Tillage-shaft-free smash-ridging tillage implement

A technology of powder ridges and tillage implements, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of slow walking speed of powder ridge machinery, low efficiency of powder ridge farming, and low efficiency, so as to improve the cutting rate and reduce the Resistance, fuel consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

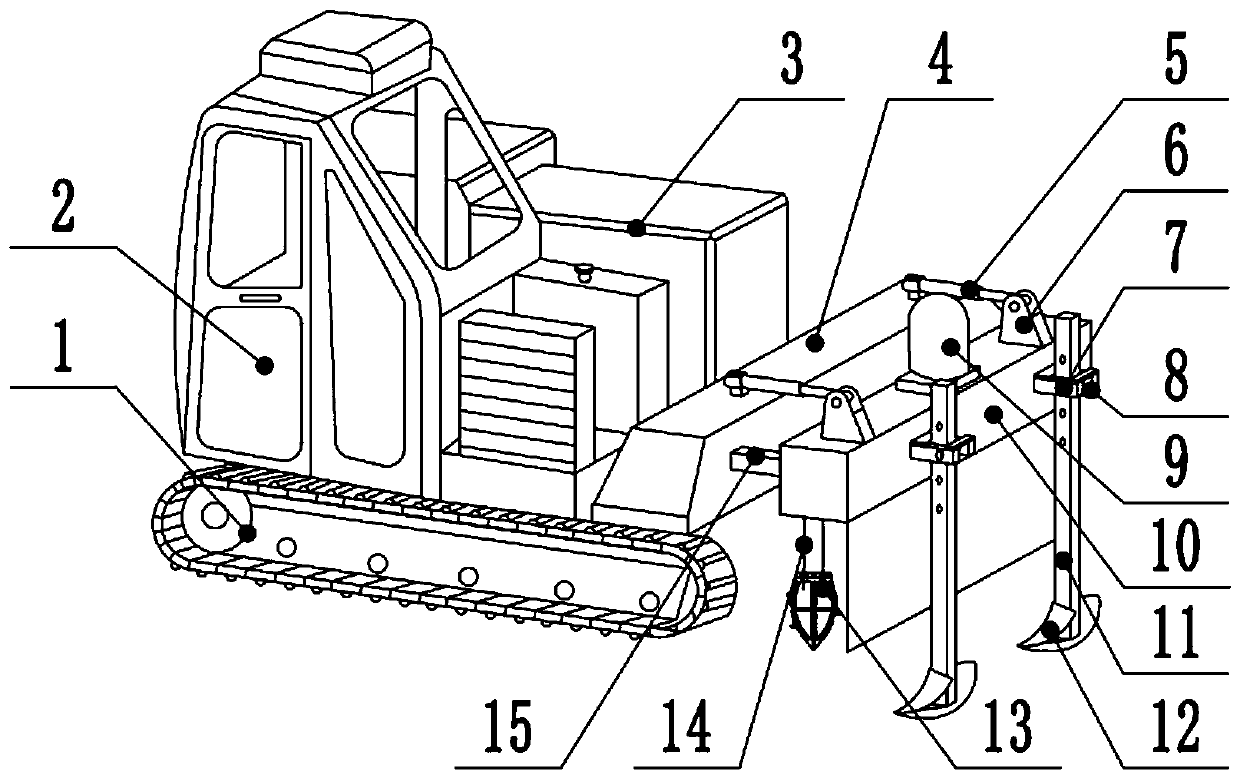

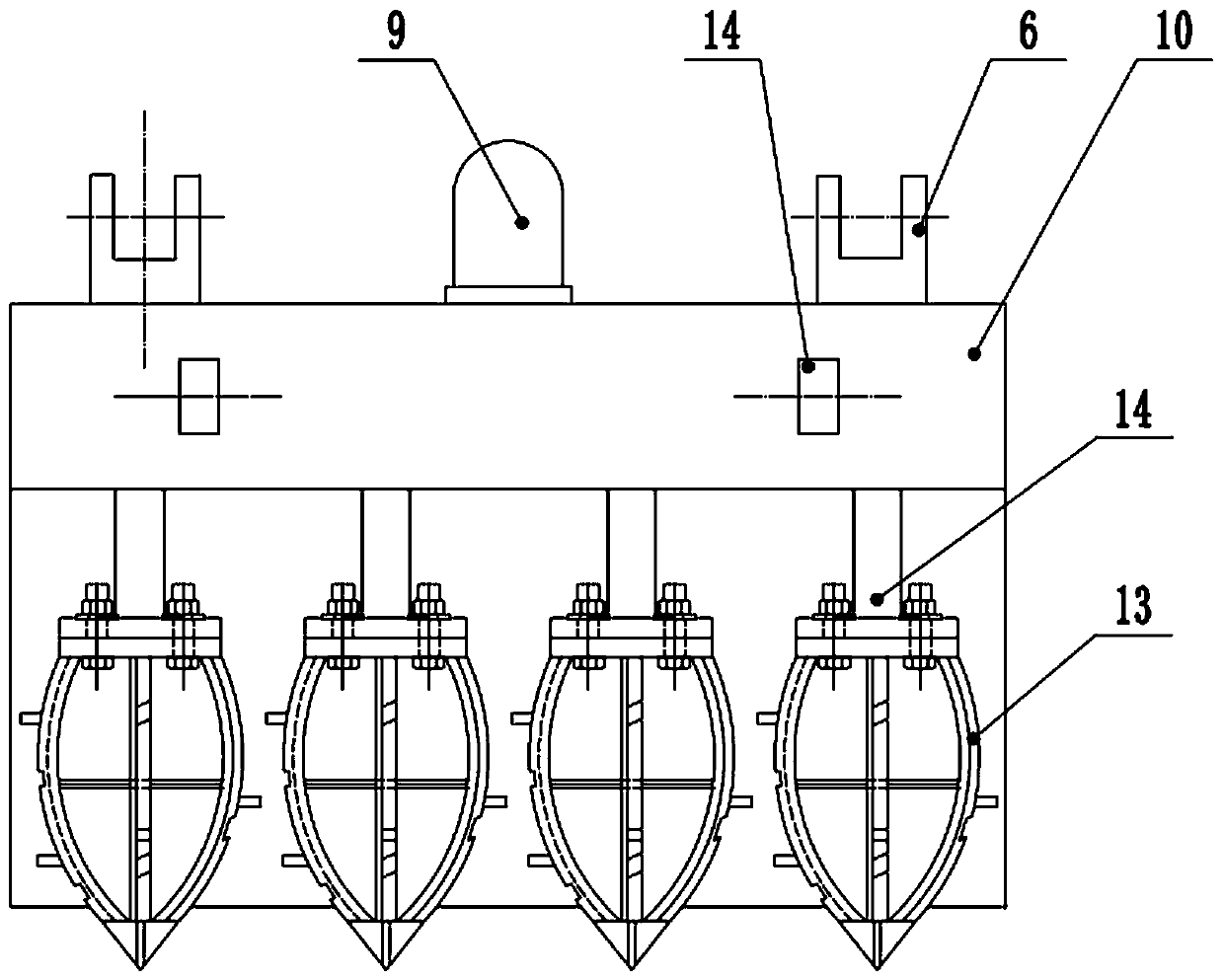

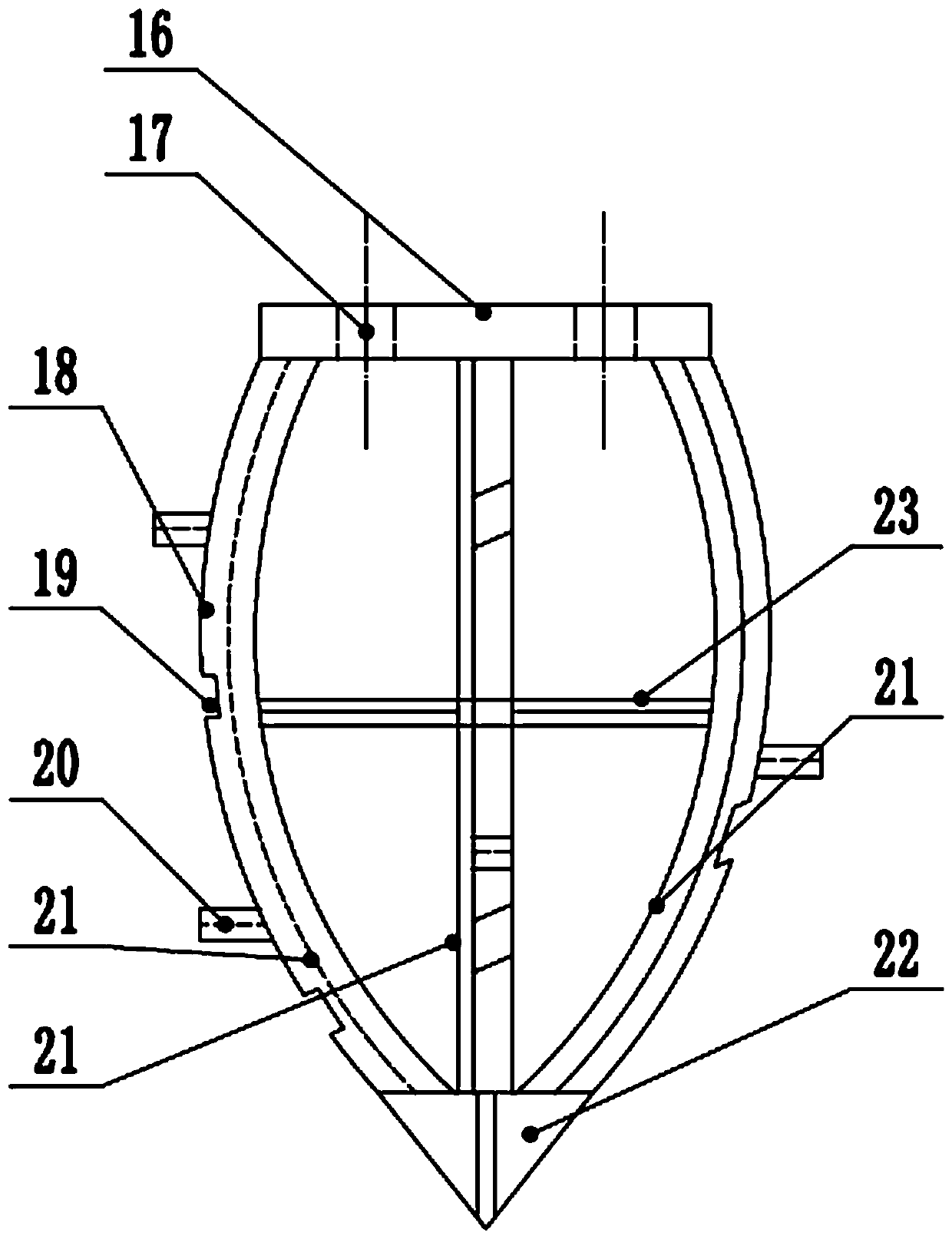

[0035] A powder ridge cultivator without tillage shaft, comprising a vehicle frame 4 and a powder ridge transmission box 10, a traveling wheel 1 is installed on the bottom of the vehicle frame 4, a cab 2 and a power unit 3 are installed on the vehicle frame 4; the powder ridge transmission box 10 Installed at the rear of the vehicle frame 4, the powder ridge transmission box 10 is equipped with an articulated arm 6, a hydraulic motor 9 and an articulated seat 15, the articulated arm 6 is connected to the vehicle frame 4 through the hydraulic cylinder 5, and the articulated seat 15 is also connected to the vehicle frame 4 The bottom of the powder ridge transmission box 10 is equipped with a shaftless vertical rotary tiller 14 driven by a hydraulic motor 9, and the vertical rotary tiller 14 without a tillage shaft is connected with the mounting seat 13 arranged at the bottom of the powder ridge transmission box 10 by bolts ; The shaft-less vertical rotary tiller 14 includes a con...

Embodiment 2

[0040] A powder ridge cultivator without tillage shaft, comprising a vehicle frame 4 and a powder ridge transmission box 10, a traveling wheel 1 is installed on the bottom of the vehicle frame 4, a cab 2 and a power unit 3 are installed on the vehicle frame 4; the powder ridge transmission box 10 Installed at the rear of the vehicle frame 4, the powder ridge transmission box 10 is equipped with an articulated arm 6, a hydraulic motor 9 and an articulated seat 15, the articulated arm 6 is connected to the vehicle frame 4 through the hydraulic cylinder 5, and the articulated seat 15 is also connected to the vehicle frame 4 The bottom of the powder ridge transmission box 10 is equipped with a shaftless vertical rotary tiller 14 driven by a hydraulic motor 9, and the vertical rotary tiller 14 without a tillage shaft is connected with the mounting seat 13 arranged at the bottom of the powder ridge transmission box 10 by bolts The described non-tilling shaft vertical rotary tiller 14...

Embodiment 3

[0046] A powder ridge cultivator without tillage shaft, which includes a tractor 25 and a powder ridge transmission box 10, the powder ridge transmission box 10 is installed at the rear of the tractor 25, and is characterized in that: the middle upper part of the powder ridge transmission box 10 is provided with an articulated arm 6. Both sides of the powder ridge transmission box 10 are respectively provided with hinged seats 15, the articulated arm 6 is connected with the middle cantilever 27 of the tractor 25, and the hinged seat 15 is connected with the side cantilever 24 of the tractor 25; whether the bottom of the powder ridge transmission box 10 is installed Vertical rotary tiller 14 with tilling shaft, and vertical rotary tiller 14 without tilling shaft are connected with mounting seat 13 arranged at the bottom of powder ridge transmission box 10 through bolts; the vertical rotary tiller without tilling shaft 14 includes a connecting plate 16. Arc-shaped rod cutters 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com