Odor removing device for clothing manufacture

A technology of fixing frame and fixing shell, applied in the field of garment processing, can solve the problems of slow deodorization rate and low deodorization efficiency, and achieve the effects of improving effectiveness, increasing deodorizing rate and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

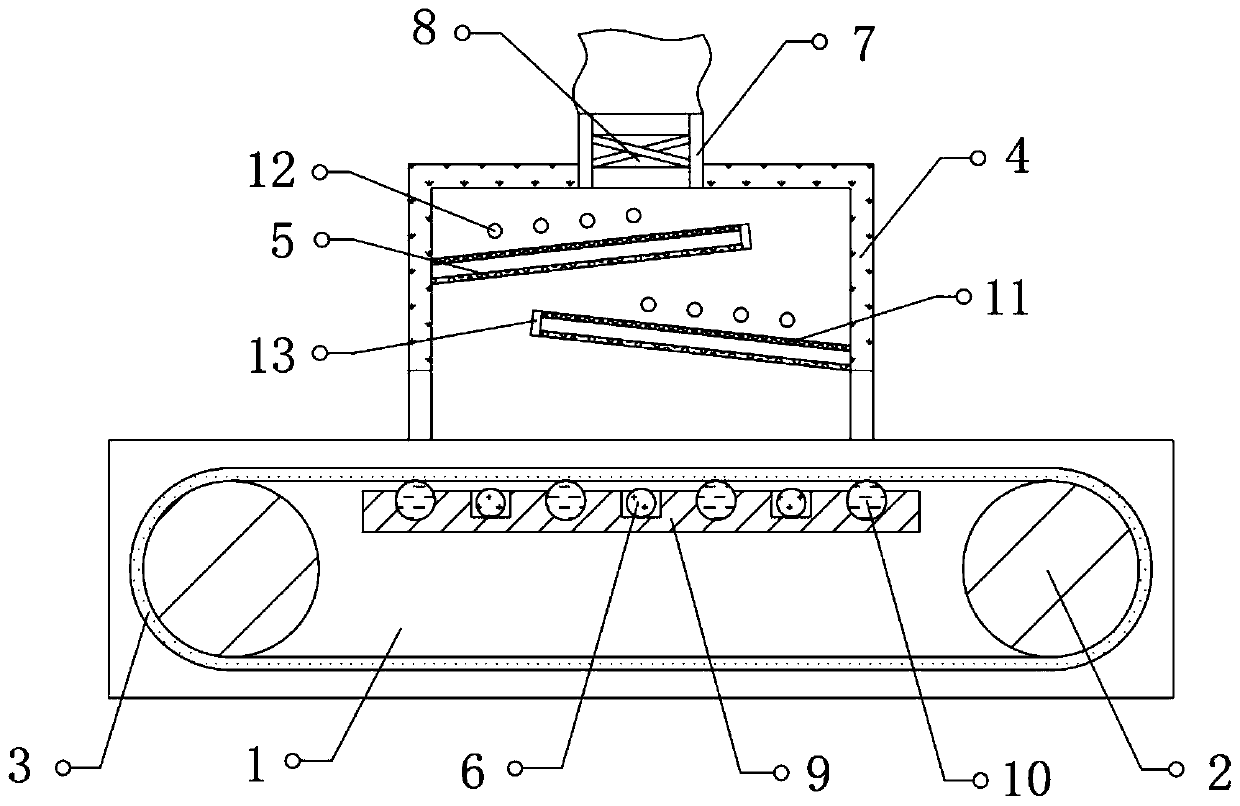

[0022] refer to figure 1 , a deodorizing device for clothing, comprising a fixed frame 1, a drive roller 2 is rotatably connected to both sides between the inner walls at both ends of the fixed frame 1, and a transmission mesh belt 3 is connected to the outer walls of the two drive rollers 2 , the top outer wall of the fixed frame 1 is fixed with a fixed housing 4 of box-like structure, and the bottom ends of both sides of the fixed housing 4 are provided with through grooves, and the inner walls of both sides of the fixed housing 4 are fixed with filter screen plates 5, An exhaust duct 7 is fixed on the top of the fixed housing 4, and an exhaust fan 8 is fixed inside the exhaust duct 7, and a plurality of heating elements 6 are fixed below the conveyor belt 3 between the inner walls at both ends of the fixed frame 1.

[0023] In the present invention, the two filter screen plates 5 are arranged to be inclined, and the inclination direction of the two filter screen plates 5 is...

Embodiment 2

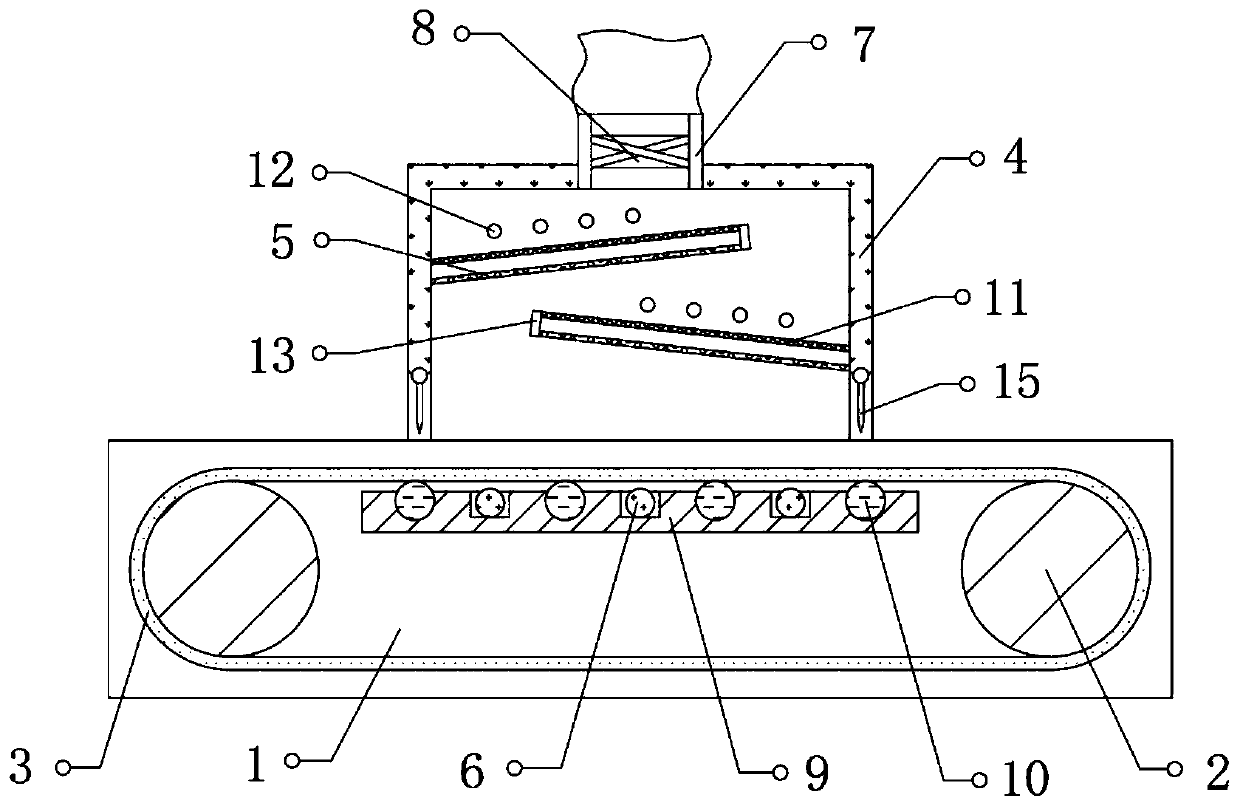

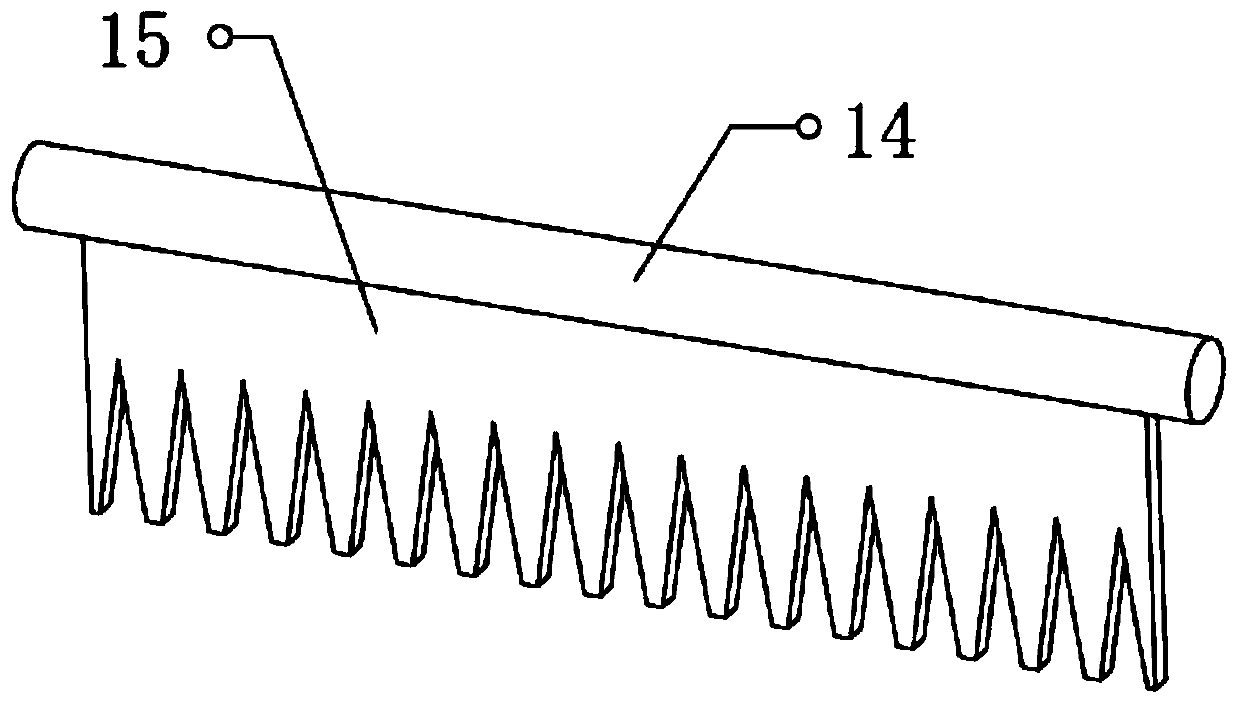

[0028] refer to Figure 2-3 , a deodorizing device for clothing, the top inner wall of the groove is rotatably connected with a fixed rod 14, and the bottom of the fixed rod 14 is fixed with a push plate 15, and one end of the fixed rod 14 is connected with a drive motor, and the bottom of the push plate 15 There are alveoli with a zigzag structure.

[0029] Working principle: Use the drive motor to make the fixed rod 14 and the push plate 15 cyclically swing at the position of the slot, so as to assist in sending the clothes that are blocked at the slot due to folding into or out of the fixed housing 4, so as to avoid the pile of clothes being blocked in the slot. location to improve the effectiveness of the device in actual use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com