Method for coating proton exchange membrane of fuel cell and coating device thereof

A technology of proton exchange membranes and fuel cells, which can be applied to devices for coating liquid on the surface, fuel cells, circuits, etc., and can solve problems such as waste of starting and stopping points of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

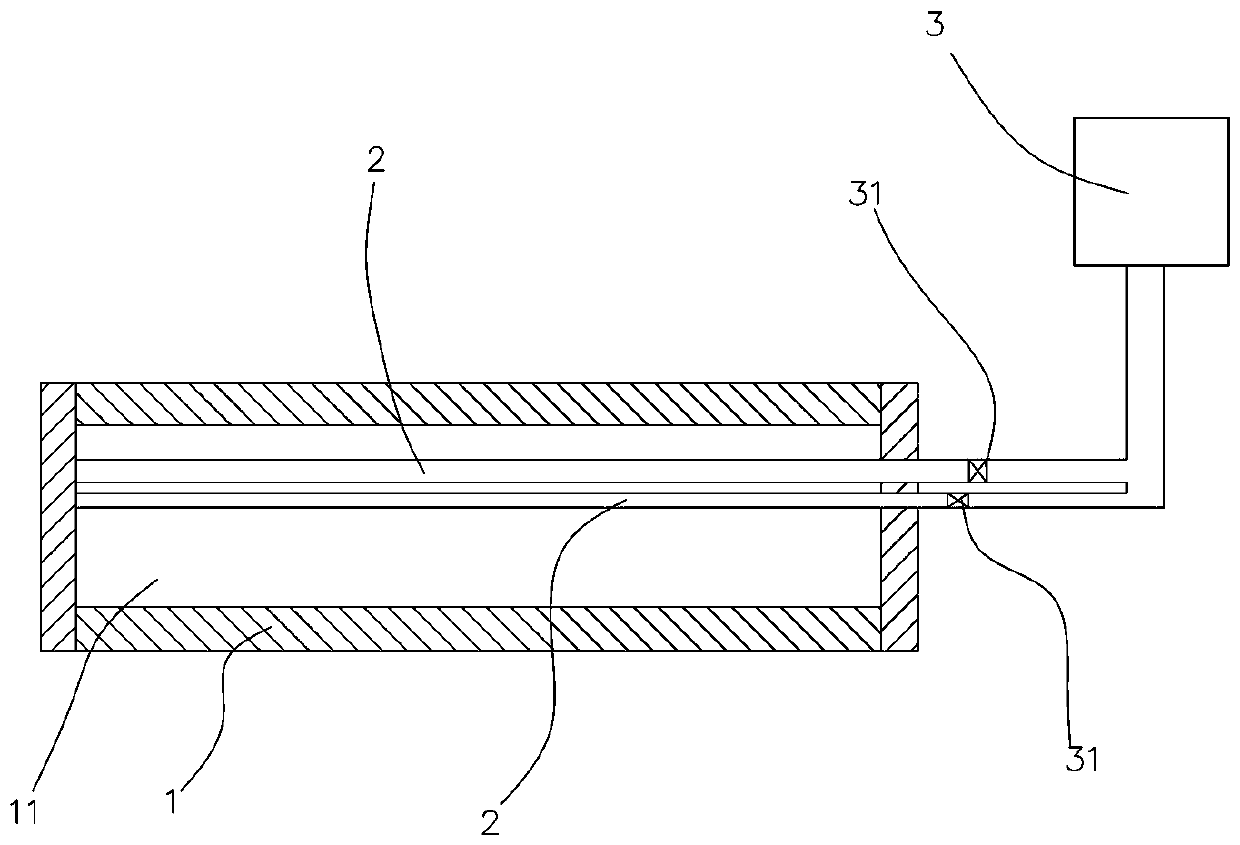

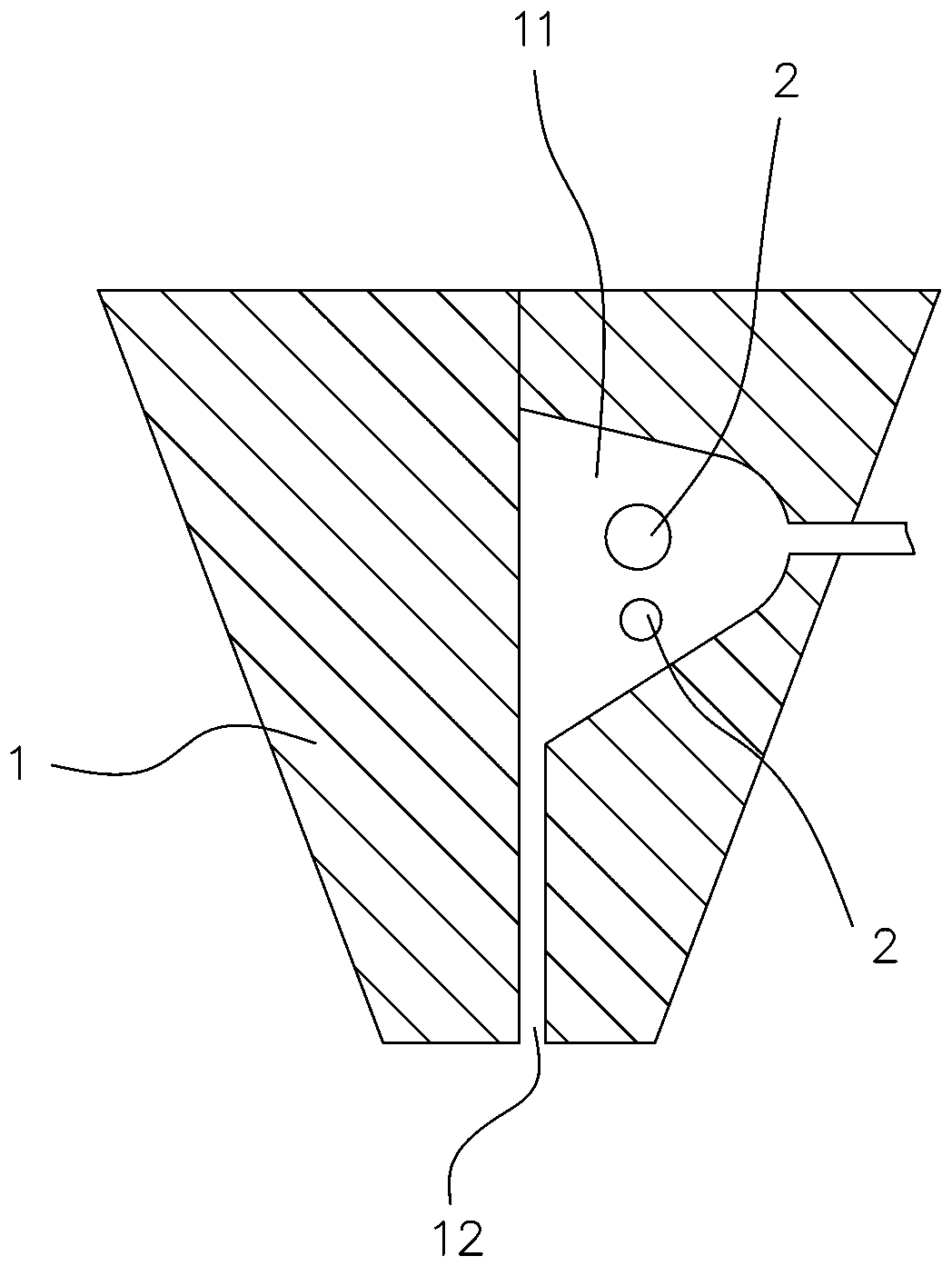

[0018] see figure 1 and figure 2 , the present invention provides a method for fuel cell proton exchange membrane coating, in which at least one expandable element 2 (in this embodiment There are two expandable elements 2, obviously, the expandable element 2 can be one, or any number of more than two), the cylinder 3 located outside the slit coating die head 1 and the expandable The element 2 communicates, and when the cylinder 3 presses the fluid into the expandable element 2, the expandable element 2 is expanded to quickly squeeze out the coating liquid; when the cylinder 3 presses the fluid from the expandable element 2 When sucked out, the expandable member 2 is contracted, thereby contracting the coating liquid from the coating port 12 of the slot coating die 1. The cylinder block 3 in the present invention can be an air cylinder or an oil cylinder, selected according to different fluids.

[0019] When the number of expandable elements 2 is more than two, the inner di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com