Standard circular radial-flow type full-automatic cleaning robot applied to secondary sedimentation tanks

A fully automatic cleaning and secondary sedimentation tank technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of time-consuming, slipping and washing away, hidden dangers, etc. Impact damage, avoid rigid collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

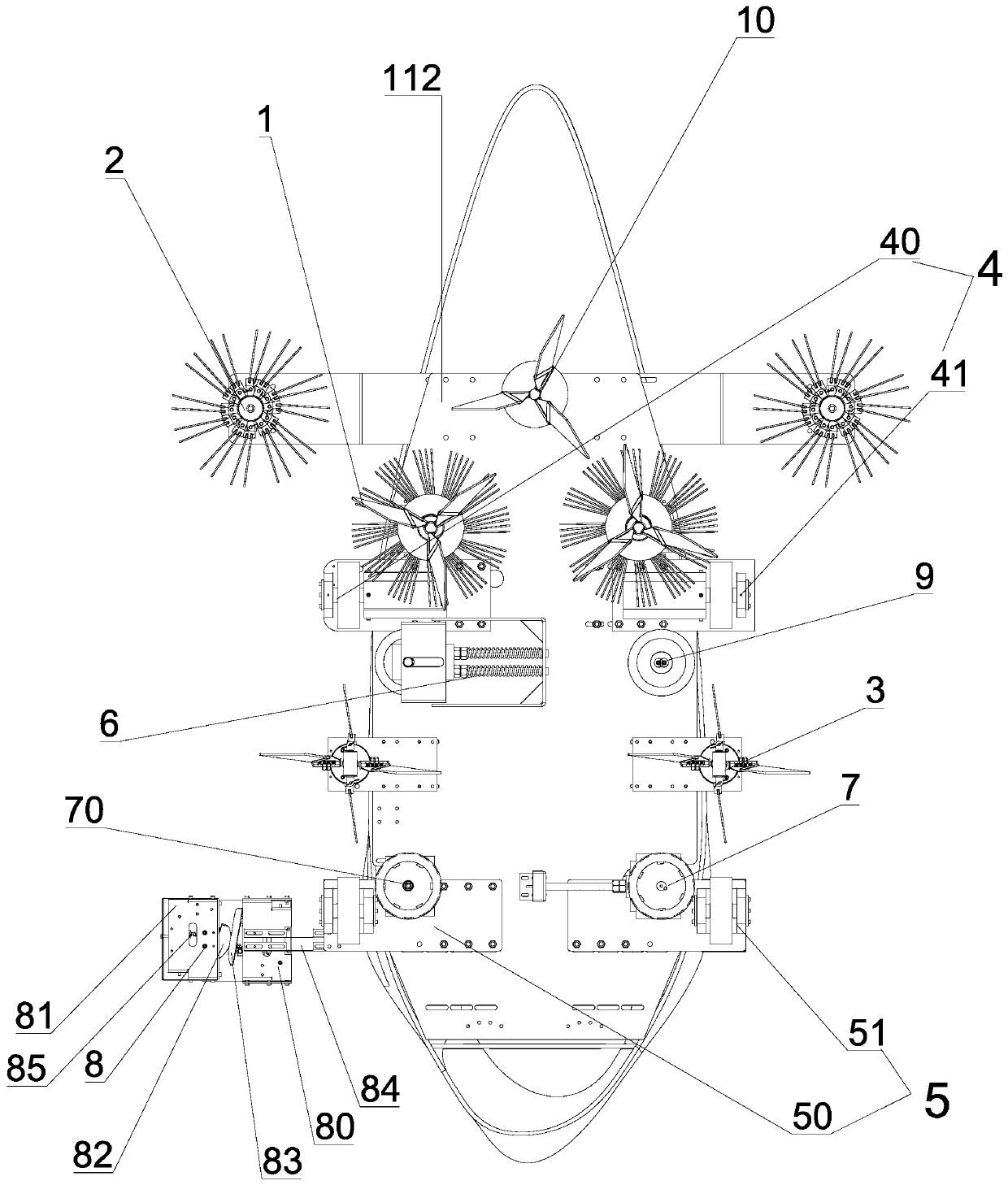

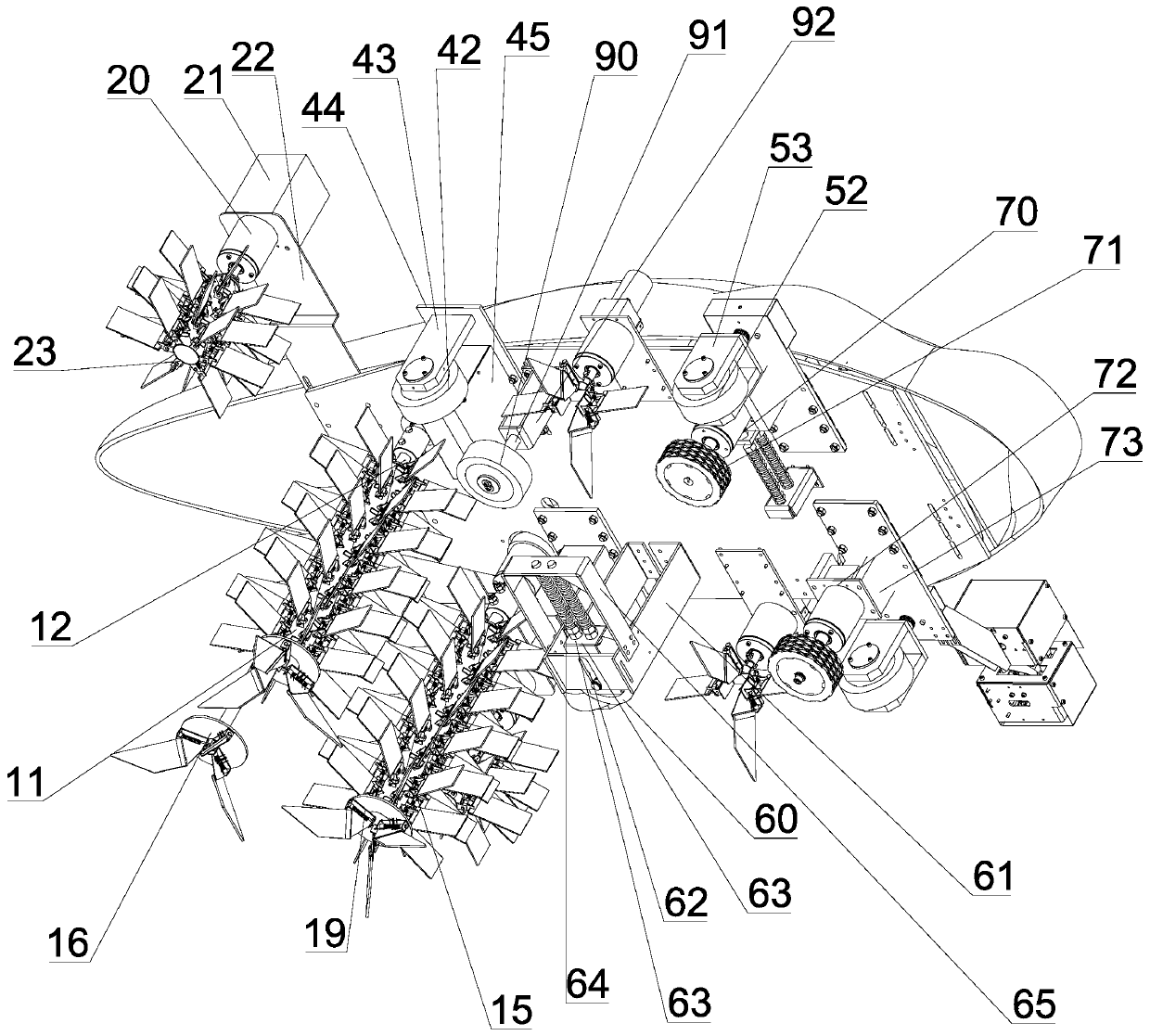

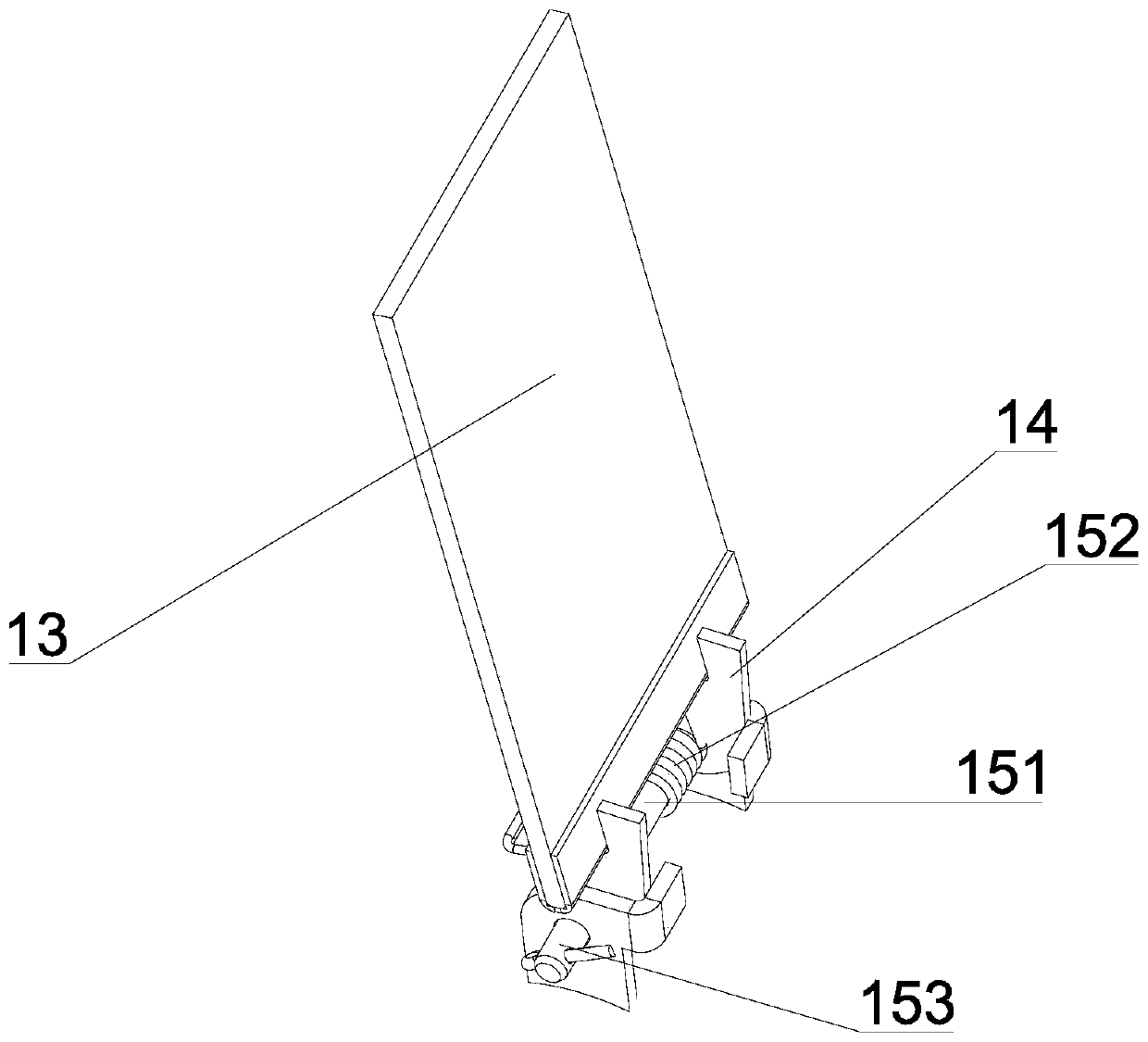

[0040] The invention relates to a standard circular radial flow type secondary sedimentation tank automatic cleaning robot, such as figure 1 As shown, it is provided with a skeleton plate 112, and the skeleton plate 112 is provided with an elastic compensation brush mechanism, a tightening positioning mechanism and a sliding automatic charging mechanism. The elastic compensation brush mechanism is provided with a main vertical spiral elastic compensation brush device 1 , an end surface elastic compensation brush device 3 , a side spiral elastic compensation brush device 2 and a bottom elastic compensation brush device 10 . The tightening positioning mechanism is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com