A method for controlling the flow channel size of closed impeller investment casting precision casting

A technology of investment precision casting and closed impeller, which is applied in the direction of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of poor dimensional accuracy, and achieve the goal of ensuring the dimensional accuracy of the flow channel, saving the trial production cycle, and reducing manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

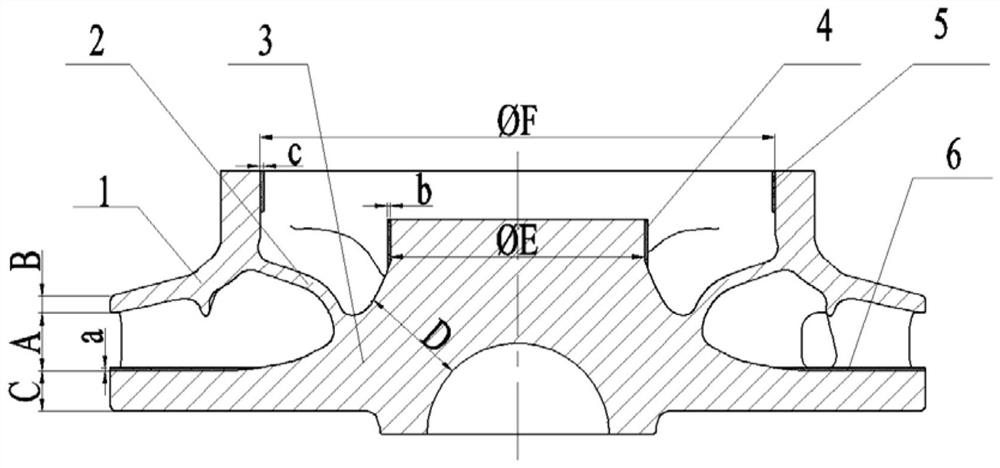

[0033] (1) When designing the investment casting mold, set the process correction amount c on the inner wall of the pouring port of the impeller curved cover plate to compensate for the size deviation of the inlet diameter ΦF after pouring is Φ170mm, and the thickness value of the process correction amount c should be controlled In 0.5 ~ 1mm;

[0034] (2) When designing the investment casting mold, set the process correction amount b on the outer surface of the flat cover plate of the impeller near the sprue to compensate for the dimensional deviation of the wheel hub diameter ΦE after pouring is Φ83mm, and the thickness of the process correction amount b The value is calculated according to the formula ΦE×(0.04-δ) / 2, where δ=0.024, ΦE=Φ83, and the thickness value of process correction b=0.66mm;

[0035] (3) When designing the investment casting mold, set the process correction amount a on the flat cover plate 3 of the impeller near the impeller outlet in the circumferential d...

Embodiment 2

[0040] (1) When designing an investment precision casting mold, set the process correction amount c on the inner wall of the pouring port of the impeller curved cover plate to compensate for the size deviation of the inlet diameter ΦF of Φ150mm after pouring, and the thickness value of the process correction amount c should be controlled In 0.5 ~ 1mm;

[0041](2) When designing the investment casting mold, set the process correction amount b on the outer surface of the flat cover plate of the impeller near the sprue to compensate for the dimensional deviation of the hub diameter ΦE of Φ75mm after pouring, and the thickness of the process correction amount b The value is calculated according to the formula ΦE×(0.04-δ) / 2, where δ=0.024, ΦE=Φ75, and the thickness value of the process correction amount b=0.6mm;

[0042] (3) When designing the investment casting mold, the process correction amount a is set on the flat cover plate 3 of the impeller near the impeller outlet in the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com