Non-contact type measuring method and device

A non-contact, measurement method technology, applied in the direction of measuring devices, mechanical measuring devices, optical devices, etc., can solve the problems of low processing efficiency and large measurement error, so as to improve processing efficiency, high measurement accuracy, The effect of high accuracy of measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

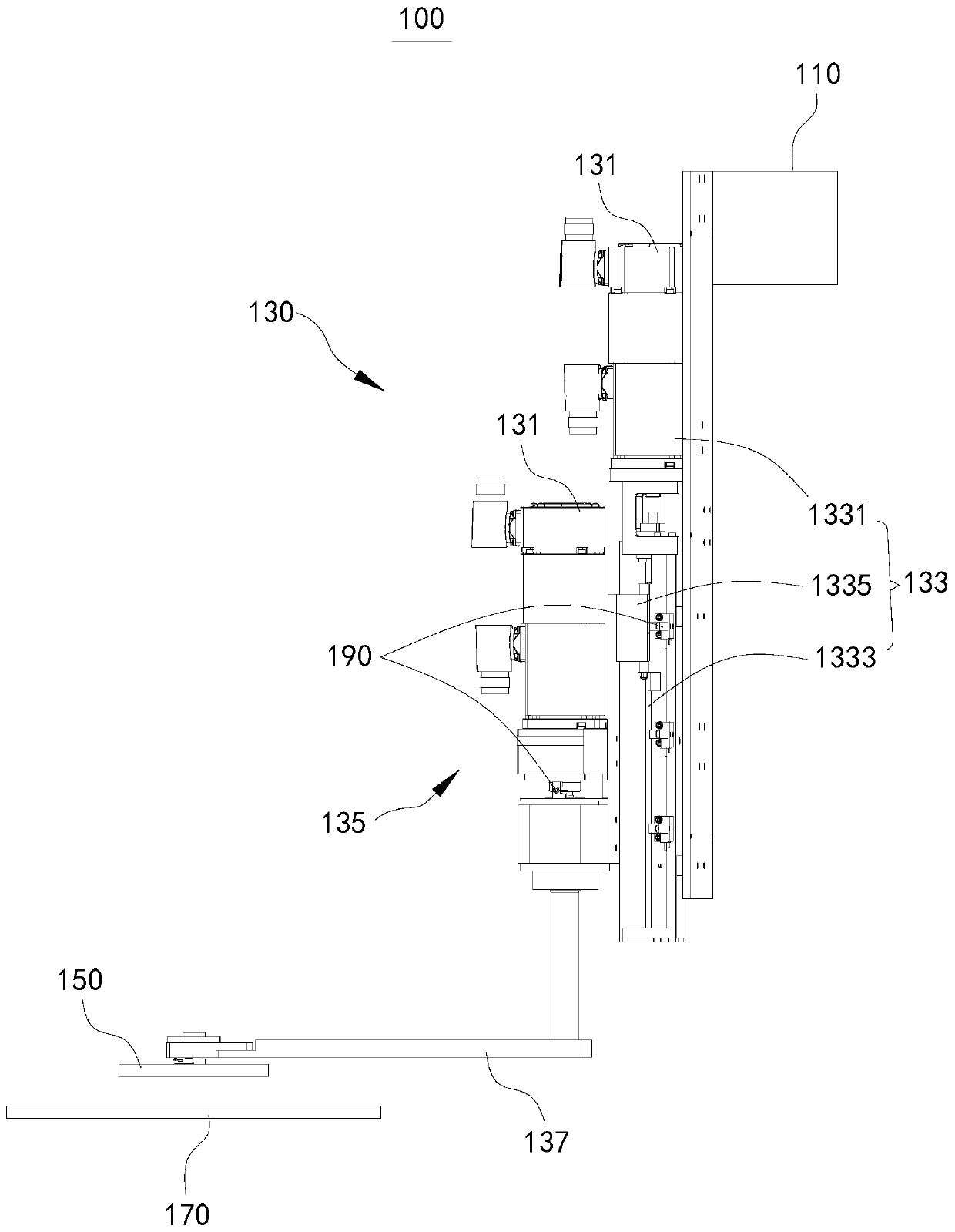

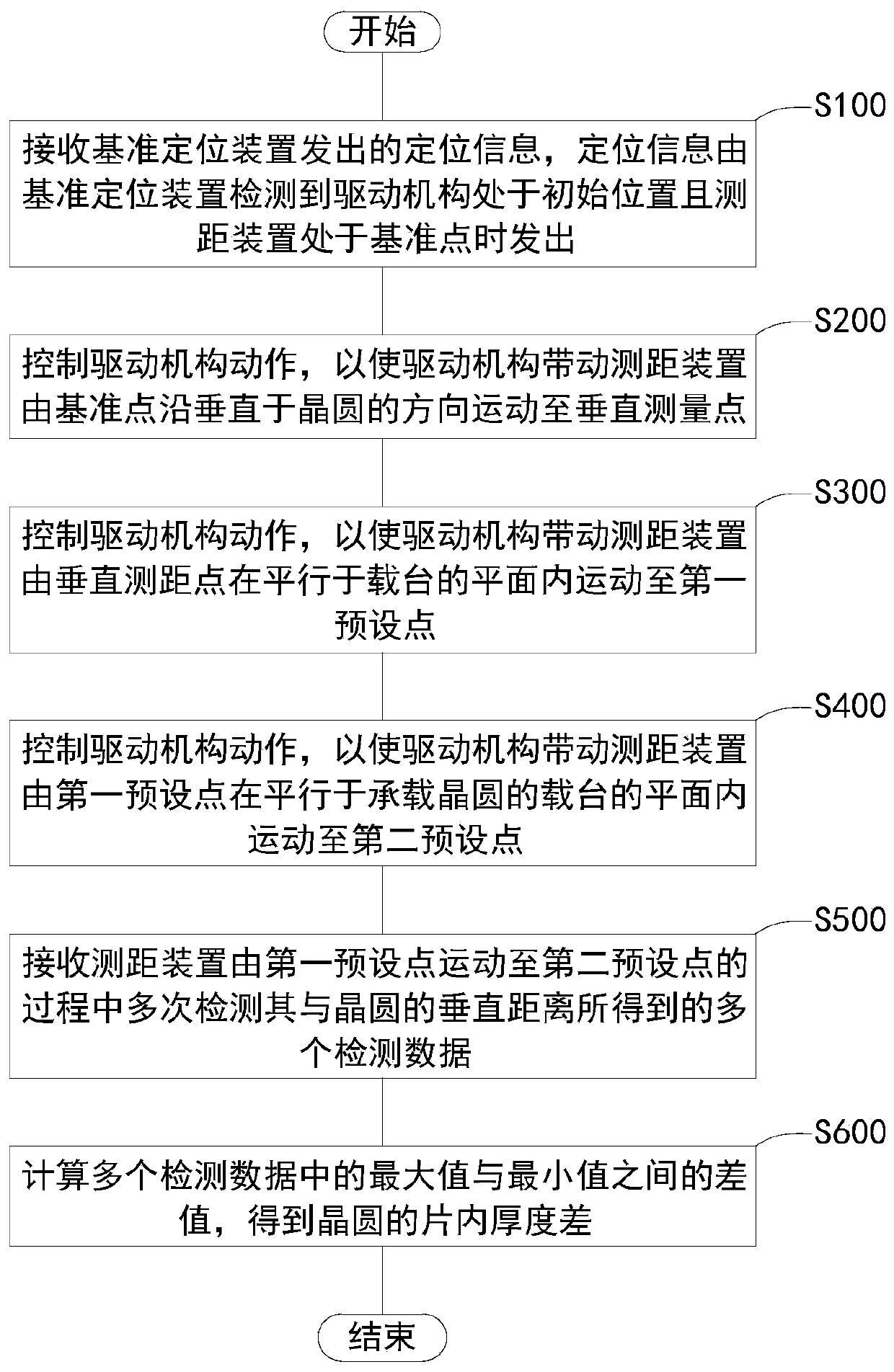

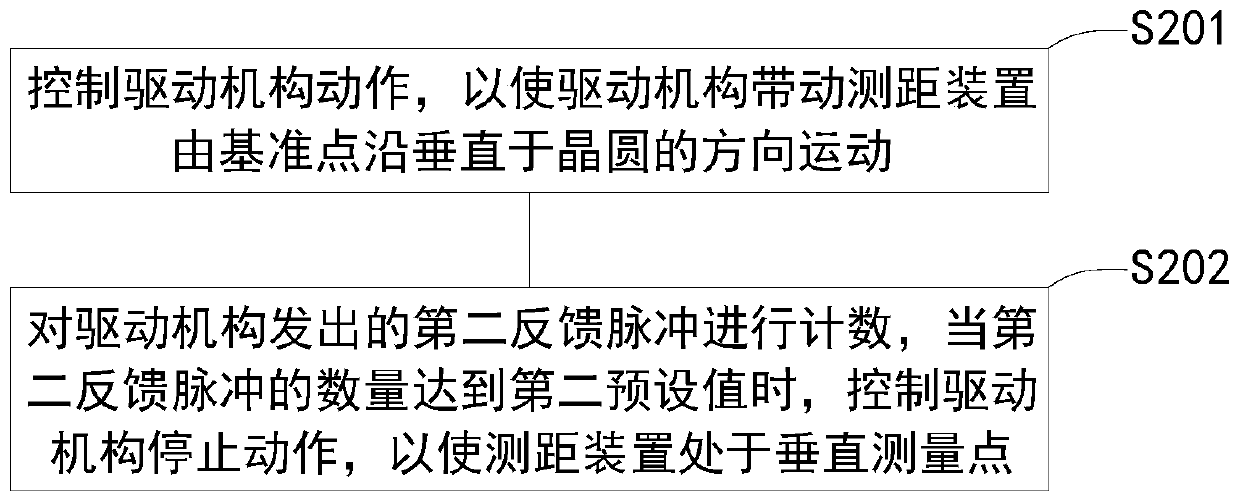

[0045] Please refer to figure 1 As shown, the non-contact measuring device 100 provided in this embodiment is used to measure the thickness difference in the wafer. The non-contact measuring device 100 can be carried out synchronously with the polishing process of the wafer, which improves the processing of the wafer. efficiency and higher measurement accuracy.

[0046] The non-contact measuring device 100 includes a controller 110, a driving mechanism 130, a distance measuring device 150, a stage 170 and a reference positioning device 190, and the controller 110 is electrically connected to the driving mechanism 130, the distance measuring device 150 and the reference positioning device 190 respectively. .

[0047] The stage 170 is used to carry the wafer, which can drive the wafer to rotate for processing such as grinding and polishing.

[0048] The distance measuring device 150 is connected with the driving mechanism 130 and is used to move relative to the wafer driven by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com