Centrifuging device for concrete pipe pile production jumping prevention

A technology for concrete pipe piles and centrifugal devices, which is applied to ceramic forming machines, manufacturing tools, etc., can solve the problems of reducing the bearing capacity of concrete pipe piles, the formation of concrete of the pile body is not compact, and the uniformity of pipe pile formation is not good, and the improvement of The effect of uniformity and stability, reducing scrap rate and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

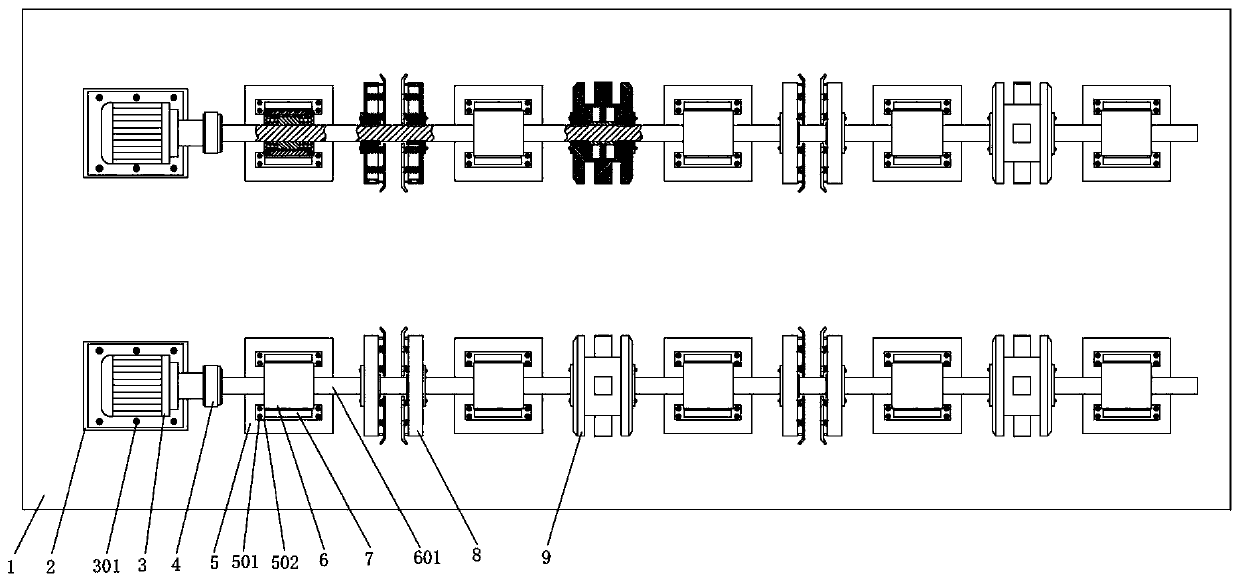

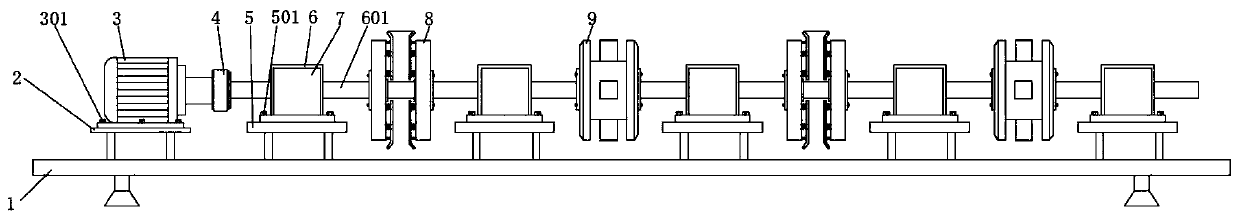

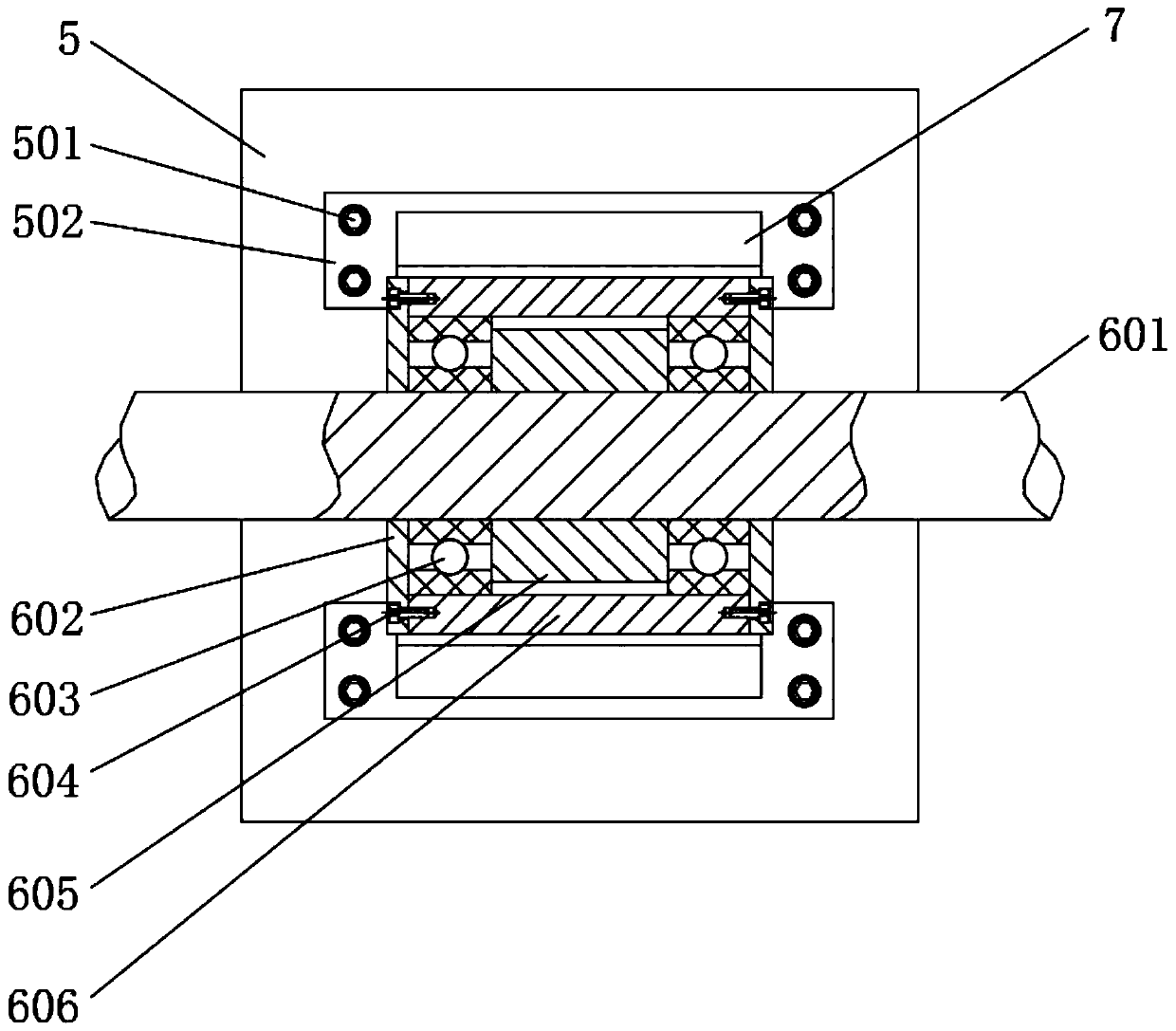

[0024] Such as Figure 1-Figure 5 As shown, the specific structure of the present invention is: it comprises a bottom plate 1, the left side of the bottom plate 1 is fixedly and symmetrically provided with a support frame 2, the top of the support frame 2 is fixedly connected with a motor 3 by a first bolt 301, and the output shaft end of the motor 3 passes through The shaft coupling 4 is connected with a rotating shaft 601, and the rotating shaft 601 is horizontally rotated and installed in the bearing mounting seat 6 to drive the motor 3, and the rotating shaft 601 rotates in the bearing mounting sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com