A packaging machine for bagged food

A technology for packaging machinery and food, which is applied in the field of food processing, can solve the problems of food splashing affecting the loading operation, etc., and achieve the effect of improving the actual use effect, enhancing the actual use effect, and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

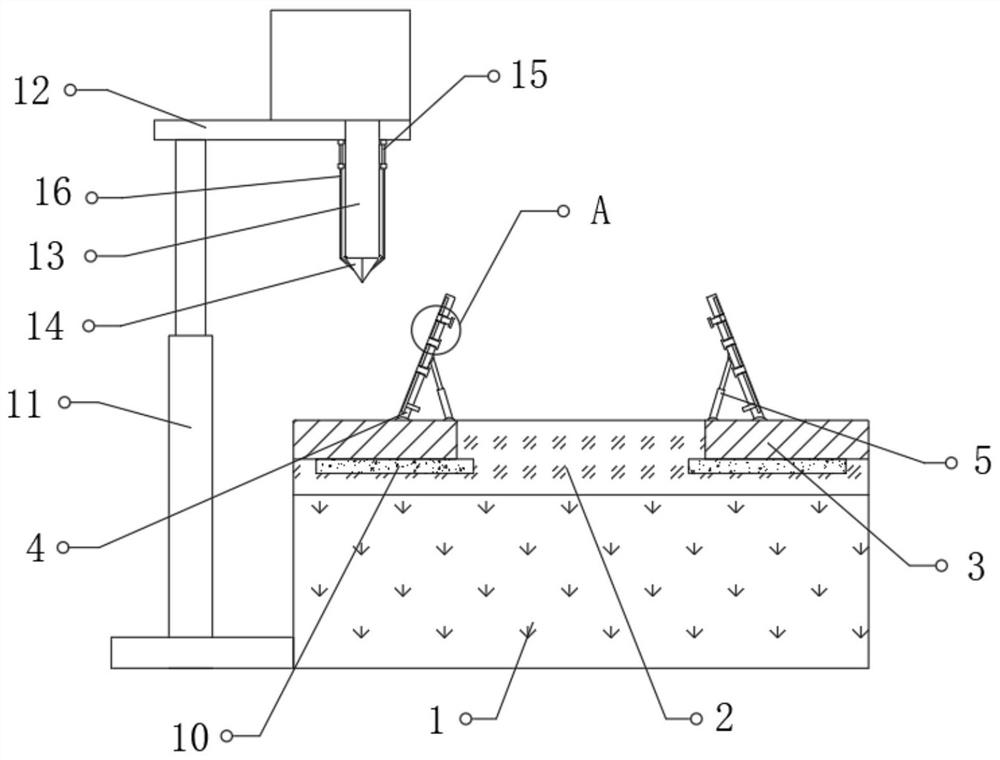

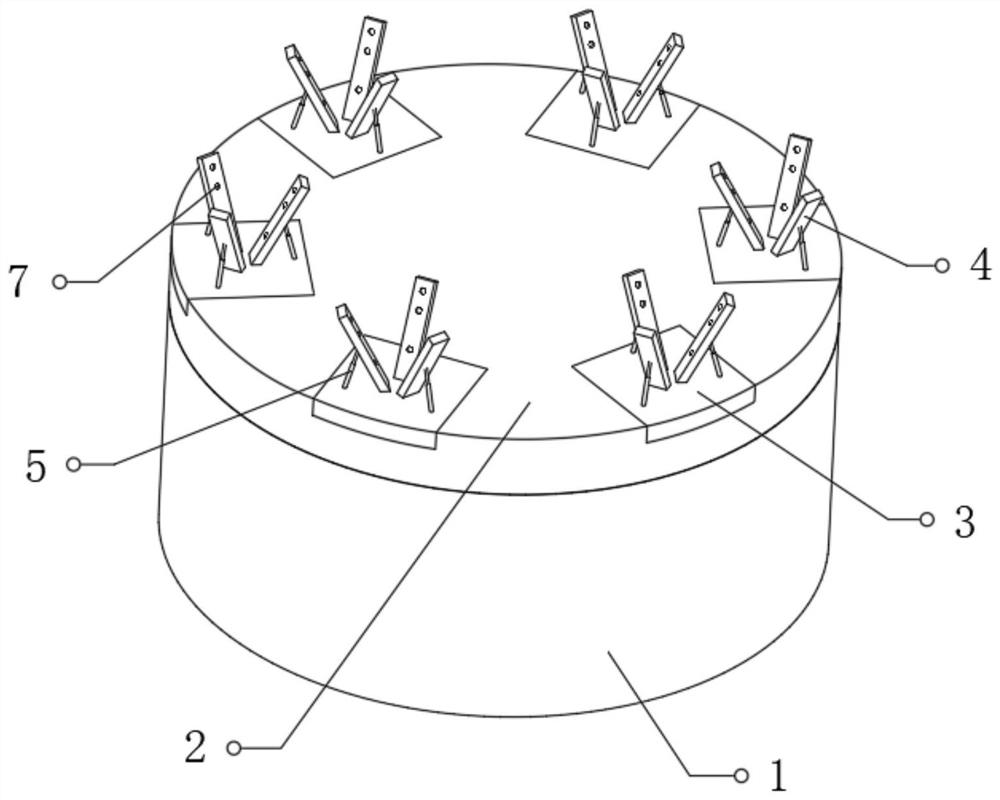

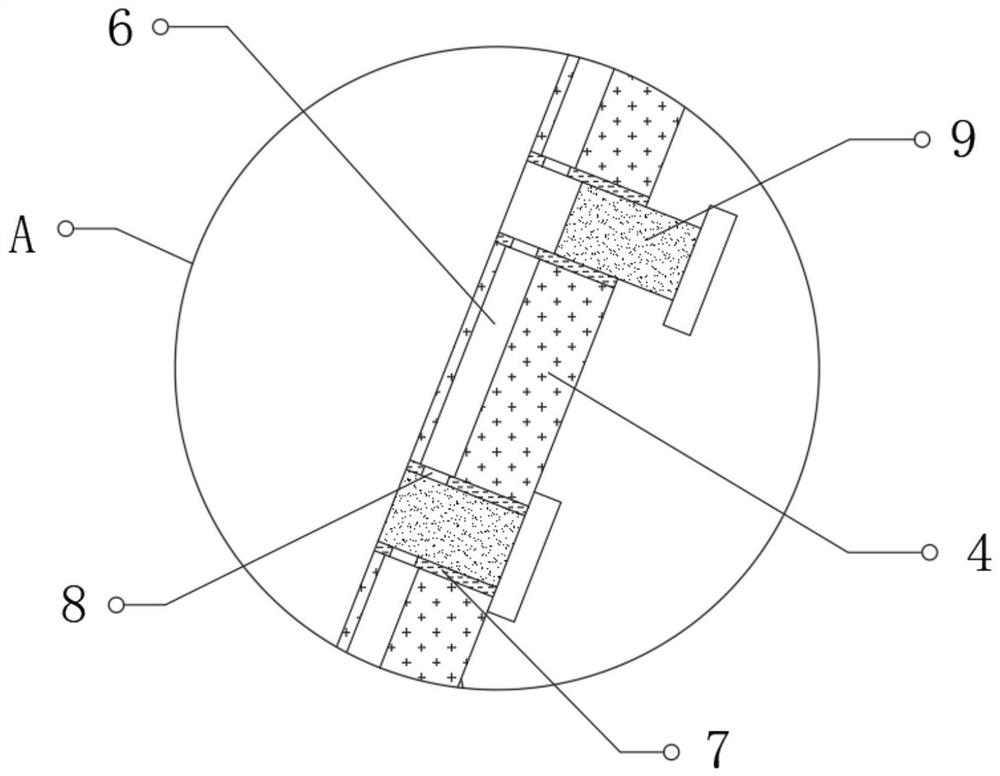

[0026] refer to Figure 1-3 , a packaging machine for bagged food, comprising a support base 1, the top outer wall of the support base 1 is rotatably connected to a turntable 2, and the bottom of the turntable 2 is connected to a drive motor, and the top of the turntable 2 is provided with a plurality of fixed rings distributed in an annular array. seat 3, and the top outer wall of the fixed seat 3 is rotatably connected with three adsorption seats 4 distributed in an annular array, an electric push rod 5 is connected between one side of the adsorption seat 4 and the top of the fixed seat 3, and the top of the electric push rod 5 and the bottom end are respectively rotationally connected between the adsorption seat 4 and the fixed seat 3, and the outside of the support seat 1 is provided with a bag-taking mechanism, a charging mechanism, a sealing mechanism and a bag-out mechanism.

[0027] In the present invention, the inside of the adsorption seat 4 is provided with a throug...

Embodiment 2

[0034] refer to Figure 1-4 , a packaging machine for bagged food, the top of the support seat 1 is provided with a cylindrical inner cavity, and the driving motor is fixed on the bottom inner wall of the inner cavity, and the position corresponding to the fixed seat 3 is fixed on the outer wall of the bottom of the turntable 2. 17. The negative pressure mechanism is fixed on the connecting frame 17. The outer wall of the bottom of the connecting frame 17 is provided with a plurality of first ball grooves of annular structure, and the position corresponding to the first ball groove on the inner wall of the bottom of the cavity is rotatably connected with a plurality of first ball grooves. A ball 18, rolling connection between the outer wall of the first ball 18 and the inner wall of the first ball groove;

[0035]The periphery of the outer wall of the bottom of the turntable 2 is rotatably connected with a plurality of second balls 19, and the position corresponding to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com