A fully automatic vacuum packaging unit

A vacuum packaging, fully automatic technology, applied in packaging machines, packaging, transportation packaging and other directions, can solve the problems of the product shape is not regular enough, the sealing effect is not good enough, the packaging bag damage, etc., to achieve a simple structure, reduce production steps, easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

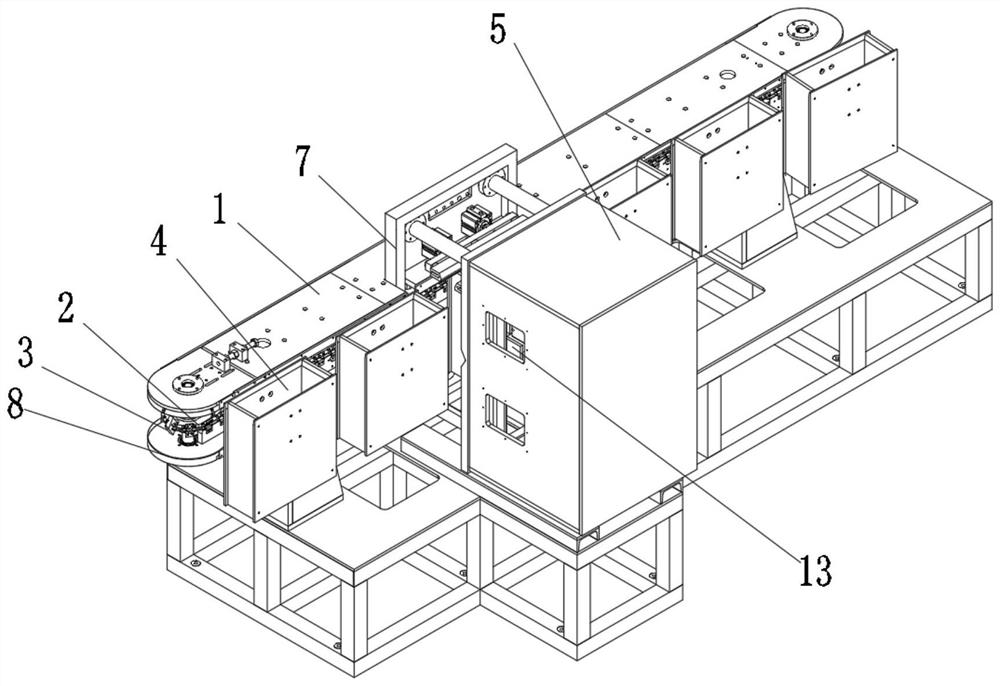

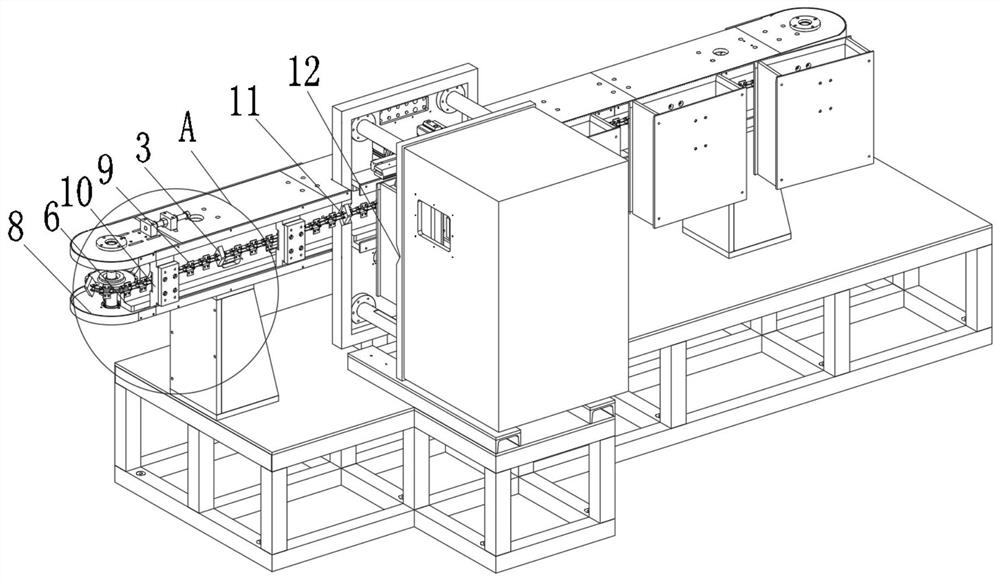

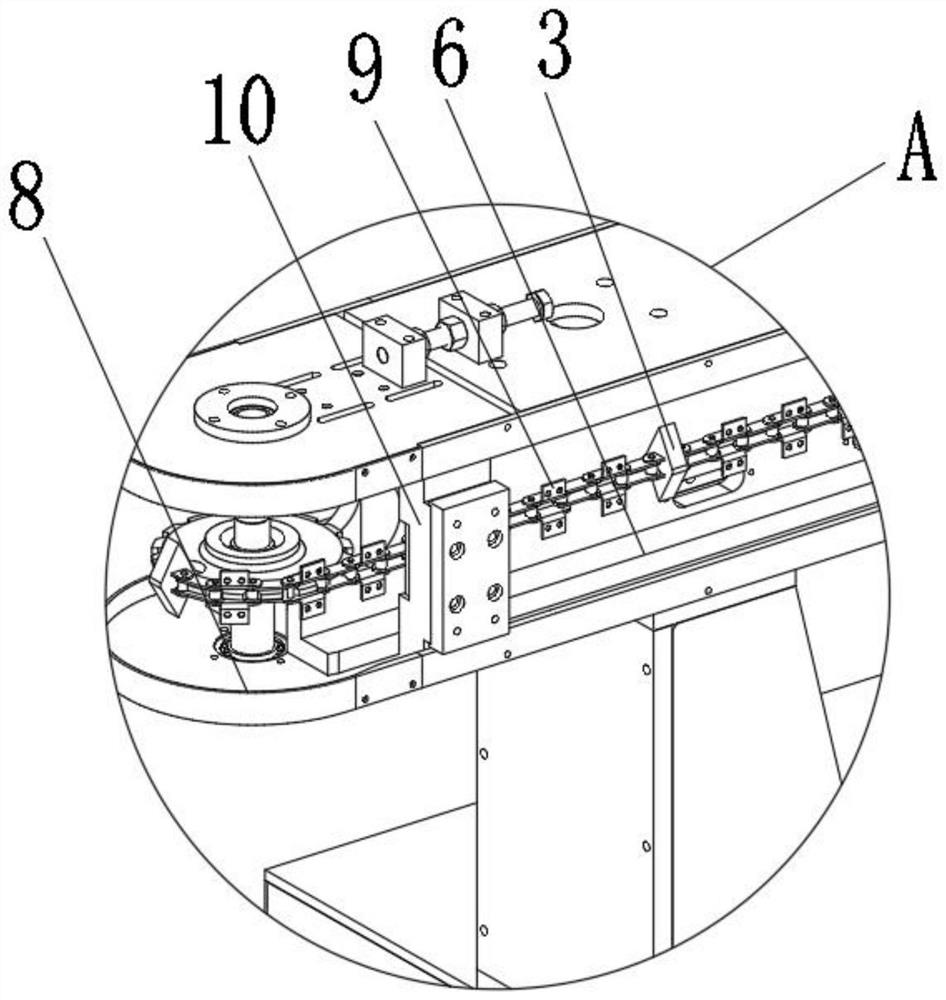

[0025] Such as Figure 1-3 As shown, a fully automatic vacuum packaging unit includes a traction mechanism 1, a traction strip 2, a seal 3, a mold cassette 4, a moving chamber 5, a telescopic mechanism (not shown in the figure), and the fixed cavity 7 and the extravagant The heat uniform, the traction mechanism 1 is provided with a circulating strip strip 2 that circulates reciprocating rotation, and the fixing chamber 7 is fixed to the traction mechanism 1, the traction strip 2 passes between the fixing chamber 7 and the moving chamber 5, The seal 3 and the mold cassette 4 are connected to the traction strip 2, and the seal 3 is spaced apart from the mold casing 4, and the moving end of the telescoping mechanism is connected to the moving chamber 5, the method of the moving chamber 5. The sealing strip is fixed to the blue surface, so the opposite surface of the mobile chamber 5 and the fixed chamber 7 is connected by a sealing strip, and the telescoping mechanism drives the movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com