Environment-friendly mixed working medium, composition, and heat exchange system

A technology of mixing working fluids and compositions, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low refrigeration capacity and achieve good environmental performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

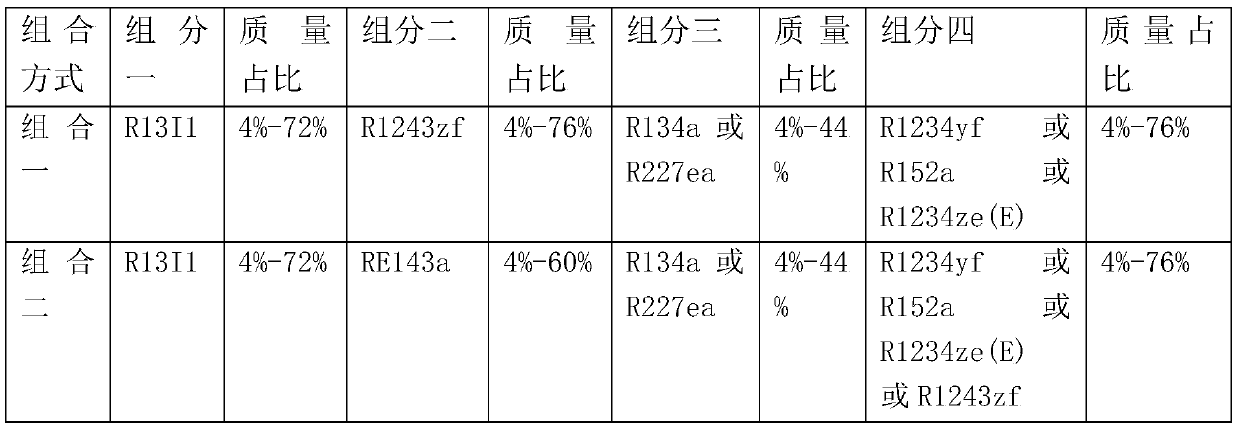

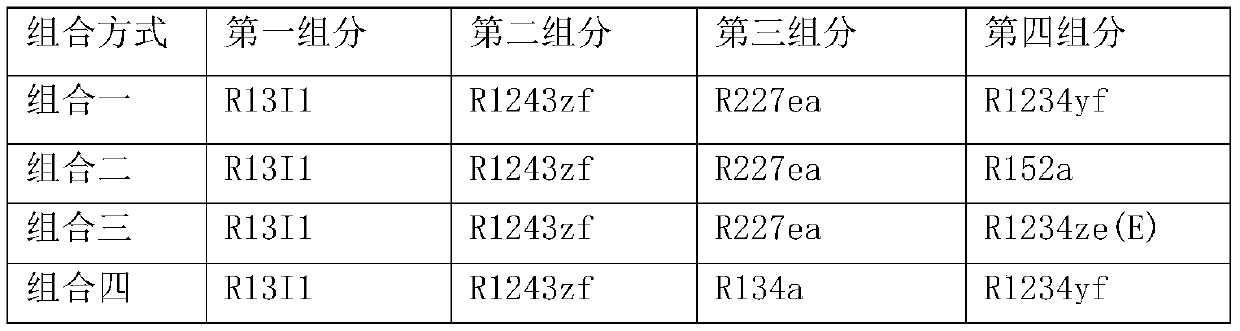

[0027] The preparation method of an environment-friendly mixed working fluid of the present invention is as follows: the first step: in trifluoroiodomethane (R13I1), 1,1,1,2-tetrafluoroethane (R134a), 1,1,1, 2,3,3,3-heptafluoropropane (R227ea) and trifluoromethyl methyl ether (RE143a) or 3,3,3-trifluoropropene (R1243zf), 2,3,3,3-tetrafluoropropene (R1234yf) ), 1,1-difluoroethane (R152a) and trans-1,3,3,3-tetrafluoropropene (R1234ze(E)) and other substances to be combined. For example, Table 1:

[0028] Table 1 Combination methods and mass proportions of refrigerants

[0029]

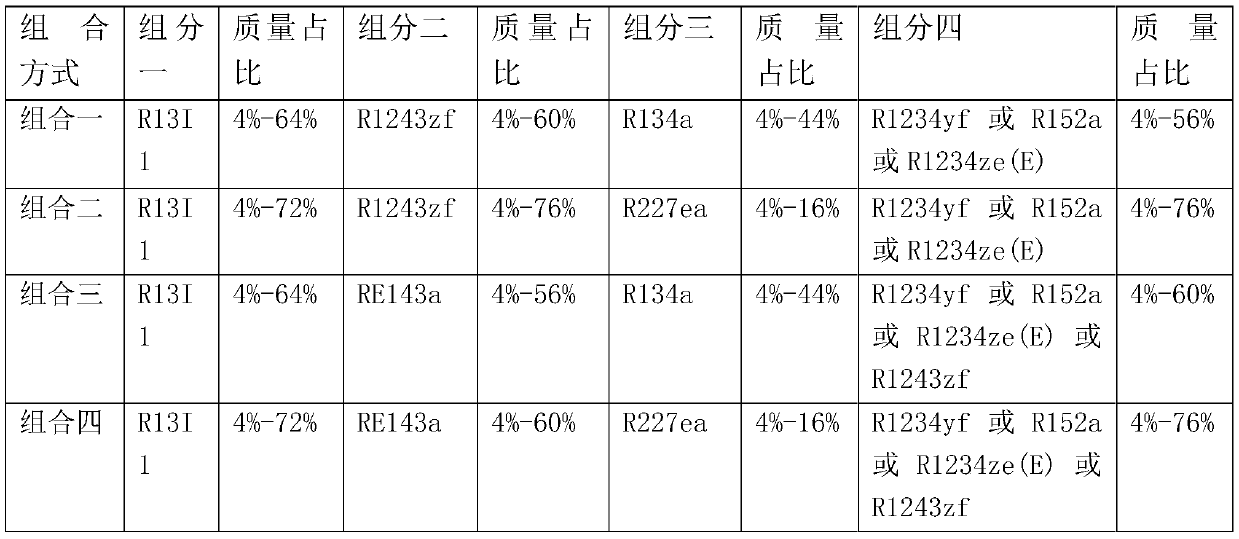

[0030] Further preferred combinations and mass ratios are as shown in Table 2:

[0031] Table 2 Combination methods and mass proportions of refrigerants

[0032]

[0033] Step 2: Carry out physical mixing in a liquid phase state at a temperature of 23°C-27°C and a pressure of 0.1 MPa according to the corresponding mass ratio of the substance, and obtain the corresponding mixed working medium aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com