Shrinkage-resistant antibacterial nano composite fiber material for extracting uranium from seawater and preparation method of shrinkage-resistant antibacterial nano composite fiber material

A nanocomposite fiber, anti-shrinkage technology, applied in seawater treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of unstable structure, easy shrinkage and antibacterial effect, and achieve improved shrinkage and degradation, significant antibacterial and antibacterial effects Anti-biofilm activity, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

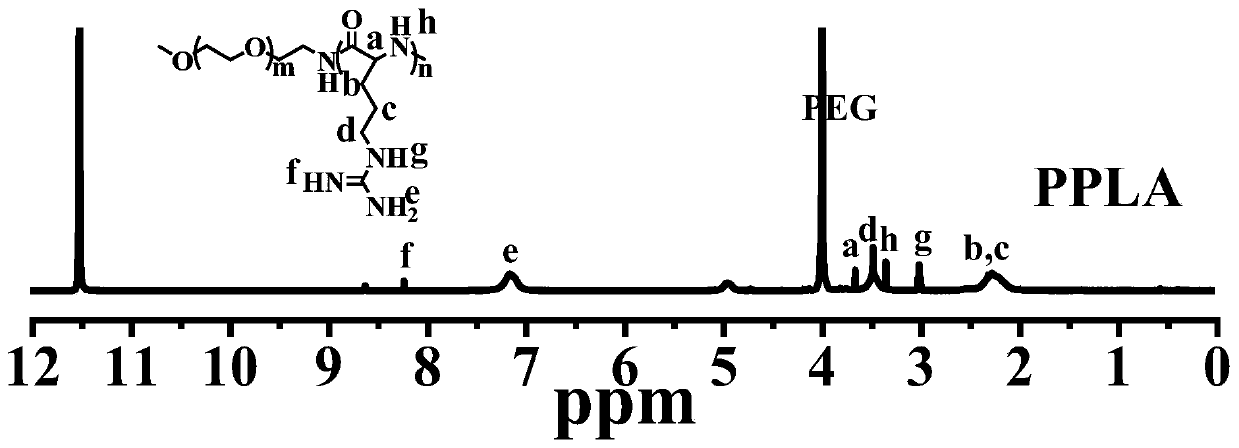

[0022] Example 1: Synthesis of methoxypolyethylene glycol-b-polyarginine diblock copolymer (PPLA)

[0023] As shown in formula 1, dissolve 2.96g of N(ε)-benzyloxycarbonyl-L-ornithine-N-carboxylic acid internal anhydride in 50mL of dry chloroform, add 1.0g of dry methoxypolyethylene glycol amine, After stirring and reacting for 3 days in an oil bath at 37°C under nitrogen protection, directly settle with ether or drain the N,N-dimethylformamide under reduced pressure. Dissolve the solid in chloroform and then settle with ether, and filter with suction. After drying under reduced pressure, the protective group was removed by trifluoroacetic acid / 33% w / w hydrogen bromide acetic acid solution (3:7v / v) to obtain methoxypolyethylene glycol-polyornithine diblock copolymer Things. Dissolve 1g of the above-mentioned diblock copolymer in 20mL of deionized water, adjust the pH to 9.0 with hydrochloric acid and sodium hydroxide aqueous solution, and then add 2.5g of 3,5-dimethyl-1-pyrazolec...

Embodiment 2

[0025] Example 2: Synthesis of polypropylene amidoxime (AOP) spinning precursor solution

[0026] As shown in formula 2, dissolve 8.5g hydroxylamine hydrochloride in 41mL DMF, add 4.6g sodium hydroxide at room temperature and stir for 4h, then add 5.0g polyacrylonitrile (PAN) to the mixed solution, stir mechanically at room temperature for 30min, and stir at 68℃ for reaction 12h. Then, it was centrifuged at 11000 rpm for 30 minutes to obtain the supernatant, which was the polypropylene amidoxime (AOP) spinning precursor solution.

[0027] Synthesis process of polypropylene amidoxime (AOP, structure is PAO or PIDO)

[0028]

Embodiment 3

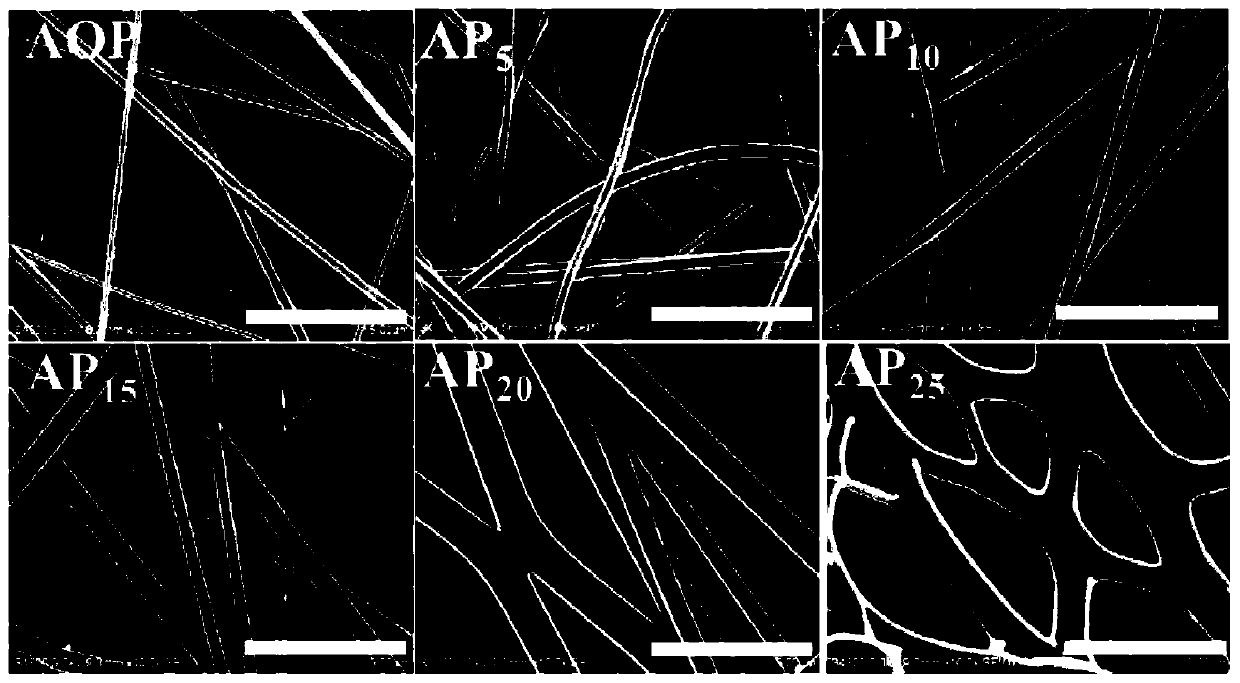

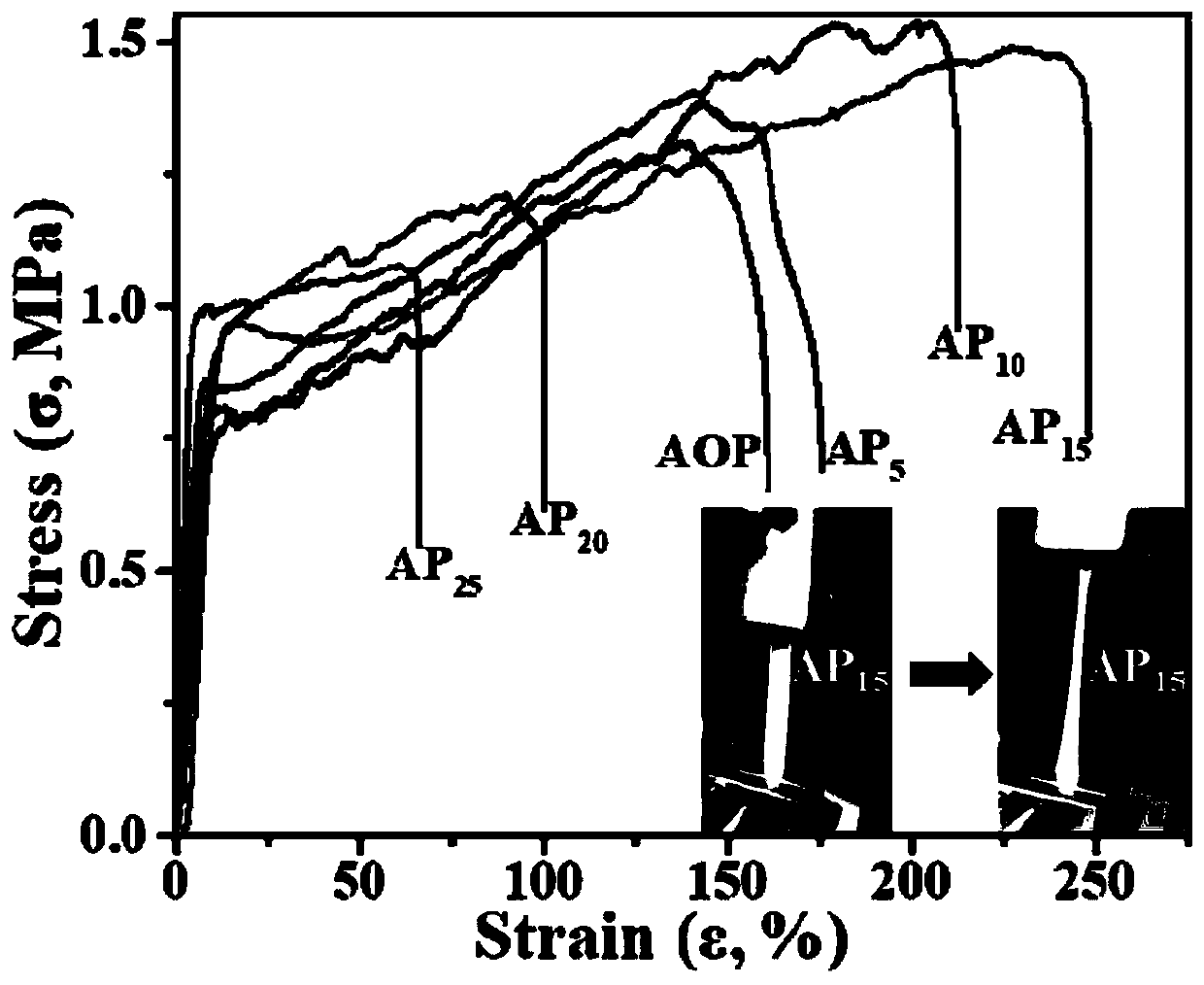

[0029] Example 3: Air-spun nanocomposite fiber (AOP / PPLA, AP x ) Preparation

[0030] Take 1g of the methoxy polyethylene glycol-b-polyarginine diblock copolymer (PPLA) prepared in Example 1, and add it at a mass concentration ratio of 15% (weight of PPLA / weight of AOP precursor solution). The 6.67 g of the polypropylene amidoxime spinning precursor solution (AOP weight / AOP precursor solution weight = 18.5%) obtained in the preparation of Example 2 was magnetically stirred and dissolved to obtain a spinning precursor mixed solution. Inject the spinning precursor mixed solution into the syringe and perform air spinning according to the following spinning parameter settings to obtain nanocomposite fiber AP x . The specific spinning operation is: an air compressor equipped with a silica gel drying tube provides dry compressed air, a syringe filled with spinning solution uses a 30G needle, and a 20kPa wind pressure and a 1mL / h advancing speed push the solution to blow the fiber , Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com