The construction method of 2 meters below the horizontal plane for green sculpture

A construction method and technology of the horizontal plane, applied in basic structure engineering, construction material processing, construction, etc., can solve problems such as incompatibility and high technical requirements for green sculpture construction, and achieve a reasonable construction method, reliable fixation, and strong stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

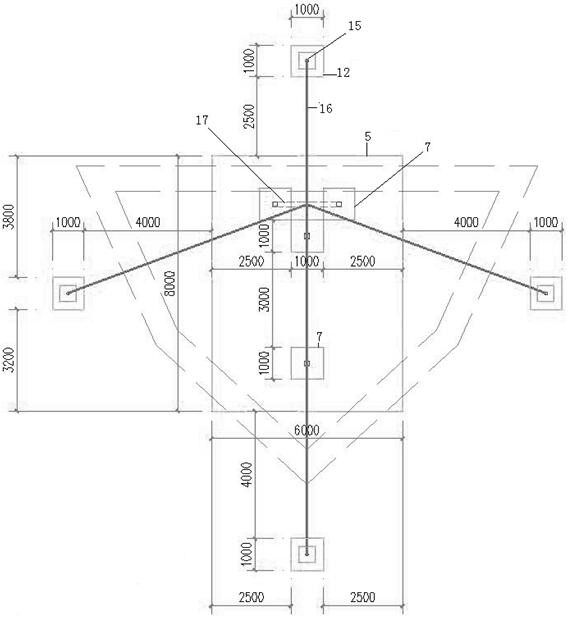

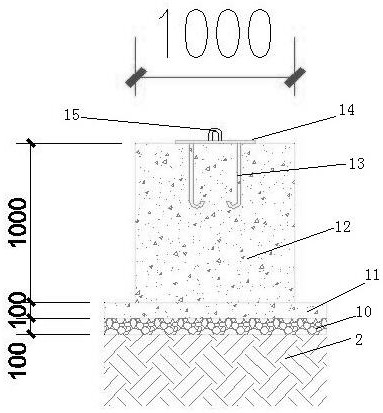

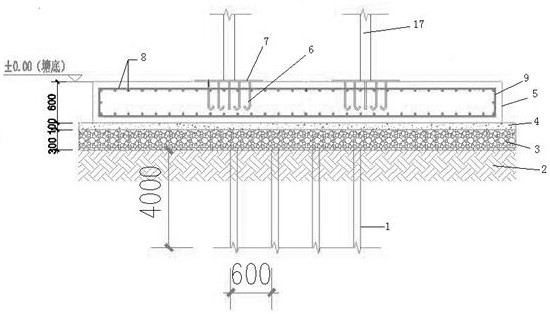

[0020] like figure 1 , figure 2 , image 3 and Figure 4 The shown construction method for the green sculpture 2 meters below the horizontal surface includes the following steps, step 1, preparation before construction, make a cofferdam around the site, and excavate a flood discharge ditch, pump away the excess water in the site, and keep it. There is no water accumulation on the internal construction surface, and the construction surface of the green sculpture base is raised to be higher than other horizontal surfaces of the entire site to prevent groundwater from overflowing the construction surface. Step 2. The construction process of the green sculpture base. Before installing the green sculpture, it is necessary to prepare the main base component and four sub-base components with a projected area of 6 meters * 8 meters and a weight of about 10 tons to support and Reinforce the entire green sculpture. Step 3. The construction process of the main structure, first use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com