High-precision granite aerostatic slideway

An air-floating guide rail, granite technology, applied in measuring devices, instruments, mechanical devices, etc., can solve problems such as the error detection accuracy of rubber discs, and achieve the effects of convenient production, reduced cost, and improved detection accuracy and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

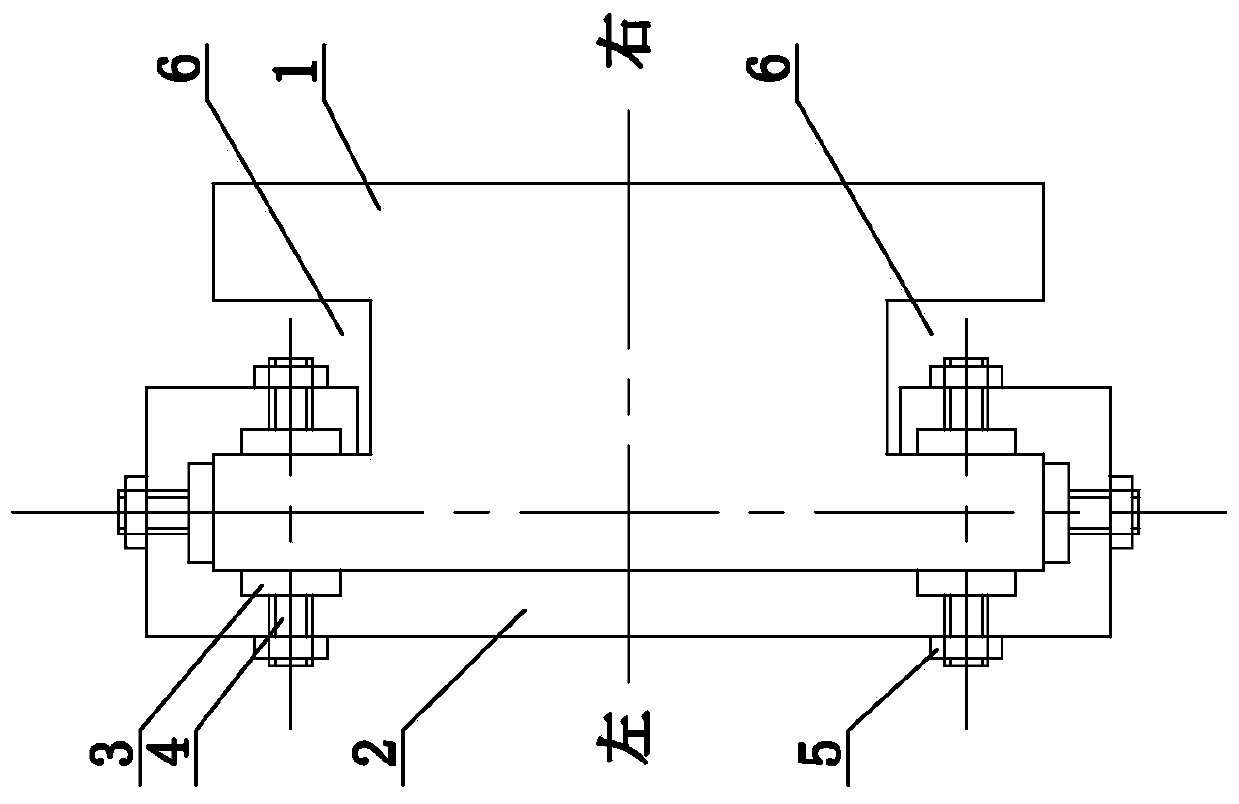

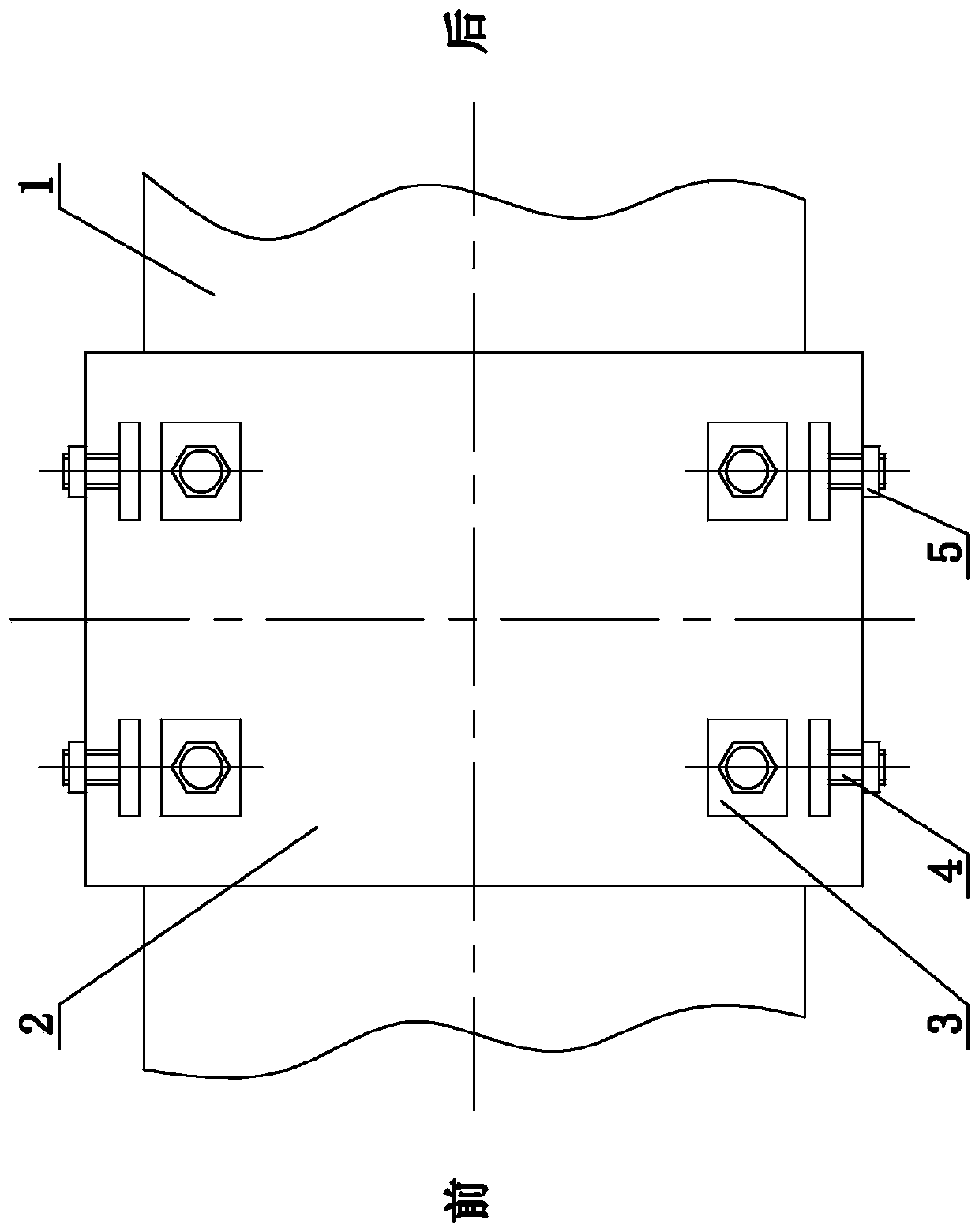

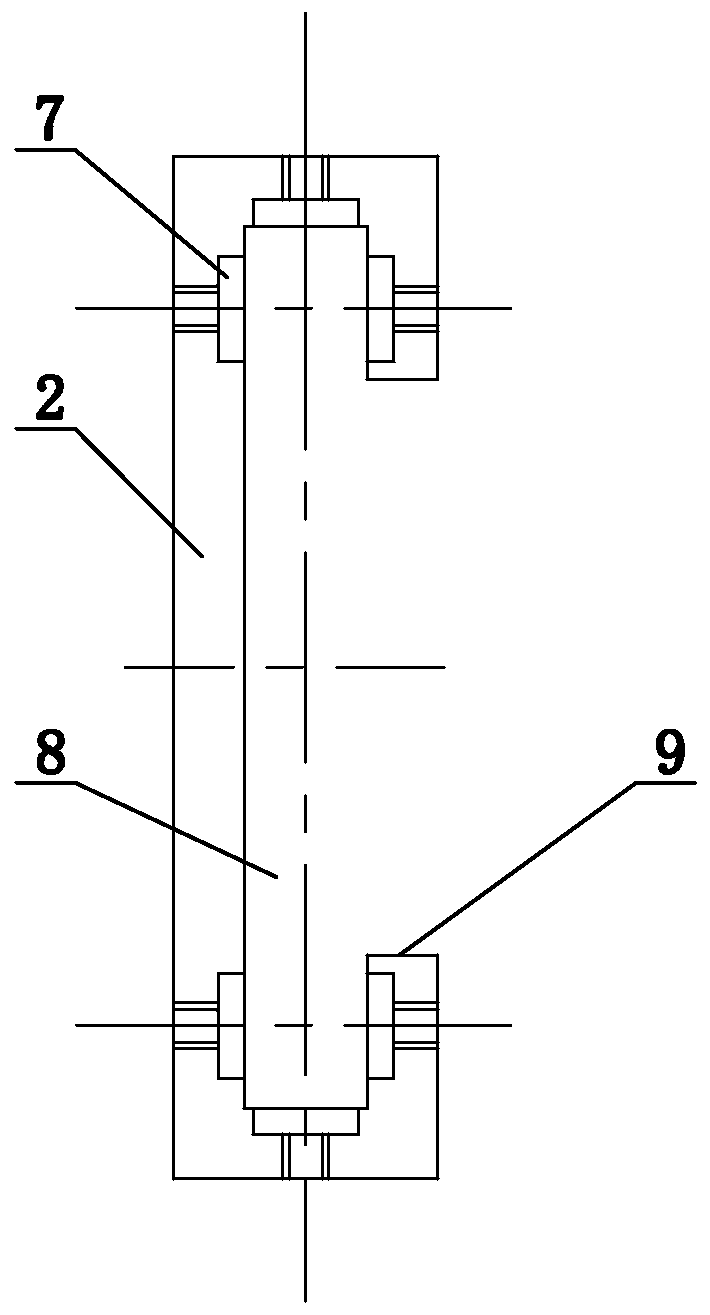

[0015] Specific implementation mode one: as Figure 1 ~ Figure 3 As shown, this embodiment discloses a high-precision granite air bearing guide rail, including a granite guide rail 1, a carriage 2, twelve air bearing blocks 3, twelve adjusting screws 4 and twelve nuts 5; the granite U-shaped grooves 6 are respectively arranged in the middle part of the upper end surface and the middle part of the lower end surface of the guide rail 1, and the two U-shaped grooves 6 are arranged opposite to each other. There are chutes, the left side and the right side of the carriage 2 are respectively provided with four threaded holes 1 arranged in a matrix form, and the upper end surface and the lower end surface of the carriage 2 are respectively provided with two threaded holes 2, which are located on the carriage 2 The two threaded holes 2 on the end surface and the two threaded holes 2 located on the lower end surface of the carriage 2 are arranged along the front and back direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com