Handle full-automatic straightening and adding equipment

A fully automatic technology for adding equipment, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low success rate of alignment, high labor cost, high labor intensity of manual assembly, etc., and achieve high success rate of adding and product damage. Small, the effect of improving stability and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

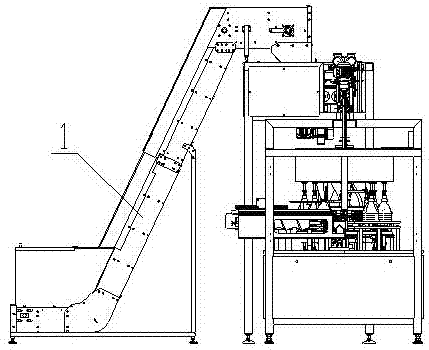

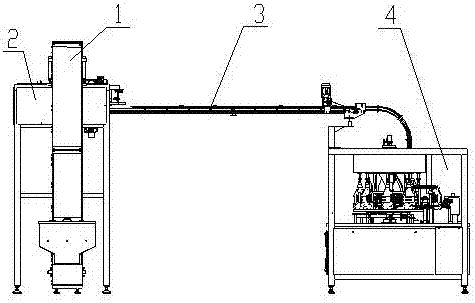

[0029] In this embodiment, a kind of automatic handle adding equipment is straightened out, see figure 1 , figure 2 , is mainly composed of four parts: chain plate hoist 1, centrifugal finishing machine 2, belt conveyor 3, and 8-station rotary adding handpiece 4.

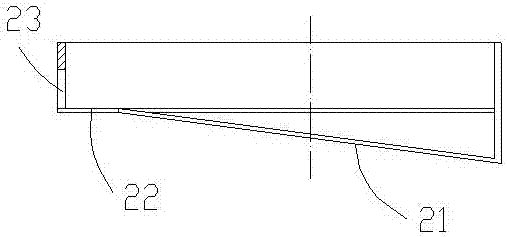

[0030] Handle products 5 such as Figure 9As shown, it has a long frame structure, the thickness of the handshake side is greater than that of the installation side, and the weight of the handshake side is also greater than that of the installation side. The handshake side surface is a curved surface, which forms a fulcrum. One end of the length direction is heavy and the other end is light. When the handle product 5 is placed flat with the curved surface as the bottom, the height of the two ends of the length direction tends to be the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com