A pallet safety recycling management system and its emergency device

A management system and emergency device technology, applied in the field of logistics management, can solve the problems of infrequent use, high logistics cost, long time consumption, etc., and achieve the effect of reducing the process of unloading and loading, ensuring normal transportation, and reducing logistics costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

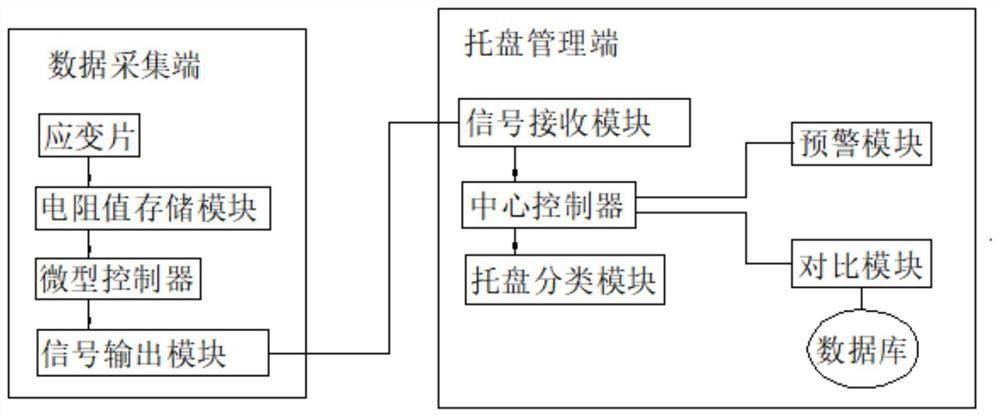

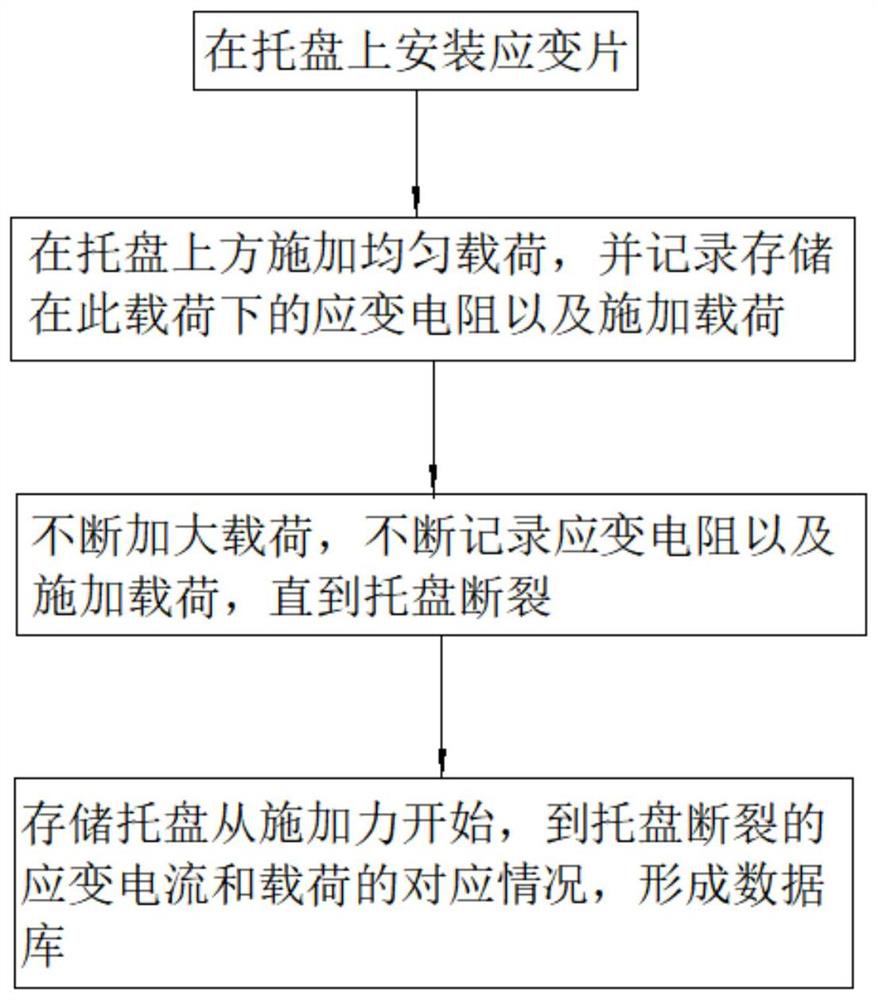

[0070] Different from Embodiment 1, this embodiment also includes a pallet damage alarm function and a pallet damage alarm step;

[0071] S21: the pallet damage alarm step is that when the strain gauge 6 detects that the pallet state corresponding to the pallet resistance value is close to the pallet end fracture value, the microcontroller will send a warning message and pallet position information;

[0072] S22: The warning information is transmitted to the signal receiving module of the pallet management end through the signal output module, and the central controller controls the early warning module to send an alarm to remind the staff to perform emergency treatment on the pallet.

[0073] In this embodiment, the pallet damage alarm function can detect the pallet is about to be damaged or has been damaged, and then the early warning module reminds the staff to sort out or replace the pallet in an emergency to ensure the safety and normal transportation of the goods on the p...

Embodiment 3

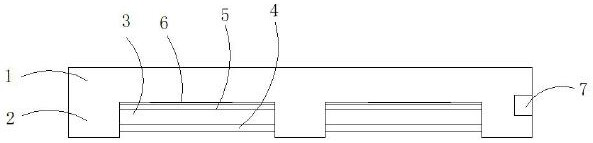

[0075] The difference between this embodiment and embodiment 2 is that an emergency device matching the tray is also provided in this embodiment, refer to Figure 6 , the shape of the emergency device is compatible with the pallet forklift port 3, and can be put into the pallet forklift port 3 for supporting the support panel 1 of the pallet. The support plate 9, the position of the movable support plate 9 can be adjusted up and down, and is used to support the tray support panel 1 that is bent in different degrees.

[0076] Specifically, refer to Figure 6 , Figure 7 and Figure 8 , the supporting body 8 is provided with an auxiliary forklift port 10, the auxiliary forklift port 10 is used to accommodate the inserting plate of the forklift, the top surface of the supporting body 8 is provided with two mounting grooves 11, and the bottom of the movable support plate 9 is provided with mounting grooves 11 is compatible with the connection block 17, the installation groove 1...

Embodiment 4

[0079] The difference of this embodiment 3 is that the connecting horizontal plate 20 and connecting screws are also set in this embodiment, refer to Figure 9 , The two sides of the supporting body 8 are provided with threaded holes, and the connecting horizontal plate 20 is provided with installation through holes, and the connecting horizontal plate 20 and the supporting body 8 can be connected by connecting screws. The connecting horizontal plate 20 in this embodiment is used to connect the emergency devices, so that multiple emergency devices can form a stable whole. When the pallet is completely damaged, the whole formed by the emergency devices can support the goods alone, which is functional and practical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com