Method for calculating contact state of assembly matching surface with geometric errors

A calculation method and technology of contact state, applied in calculation, measurement device, design optimization/simulation, etc., can solve the problems of wasting assembly time, large manufacturing error of assembly parts, and high precision requirements, avoiding the iterative solution stage and avoiding various types of problems. The effect of different, simplified calculation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

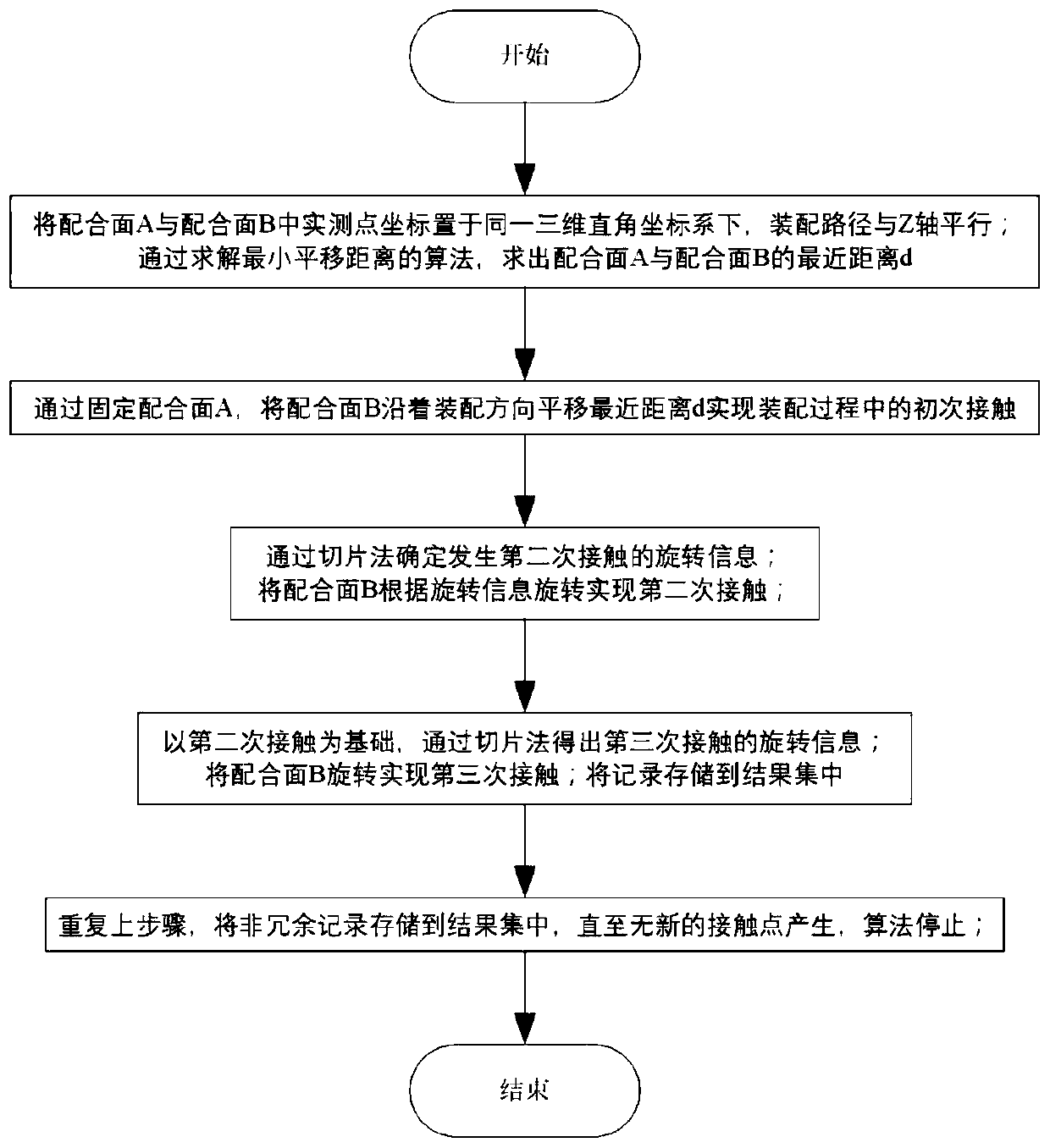

[0039] see figure 1 , the present invention provides a method for calculating the contact state of assembly mating surfaces with geometric errors, comprising the following steps:

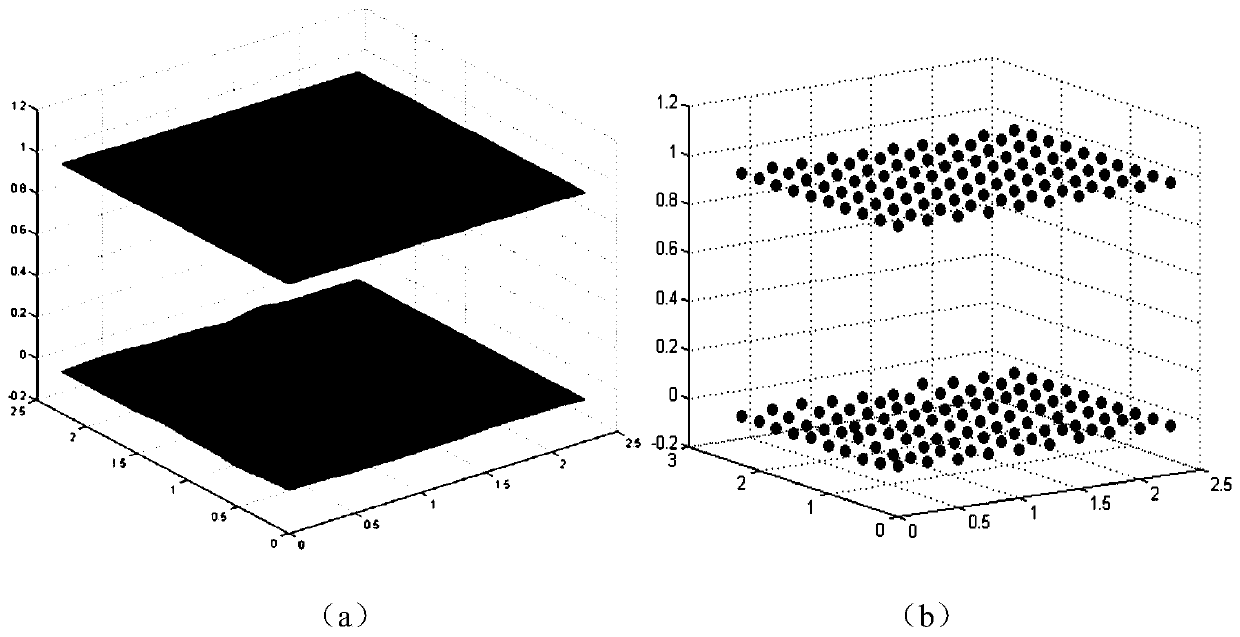

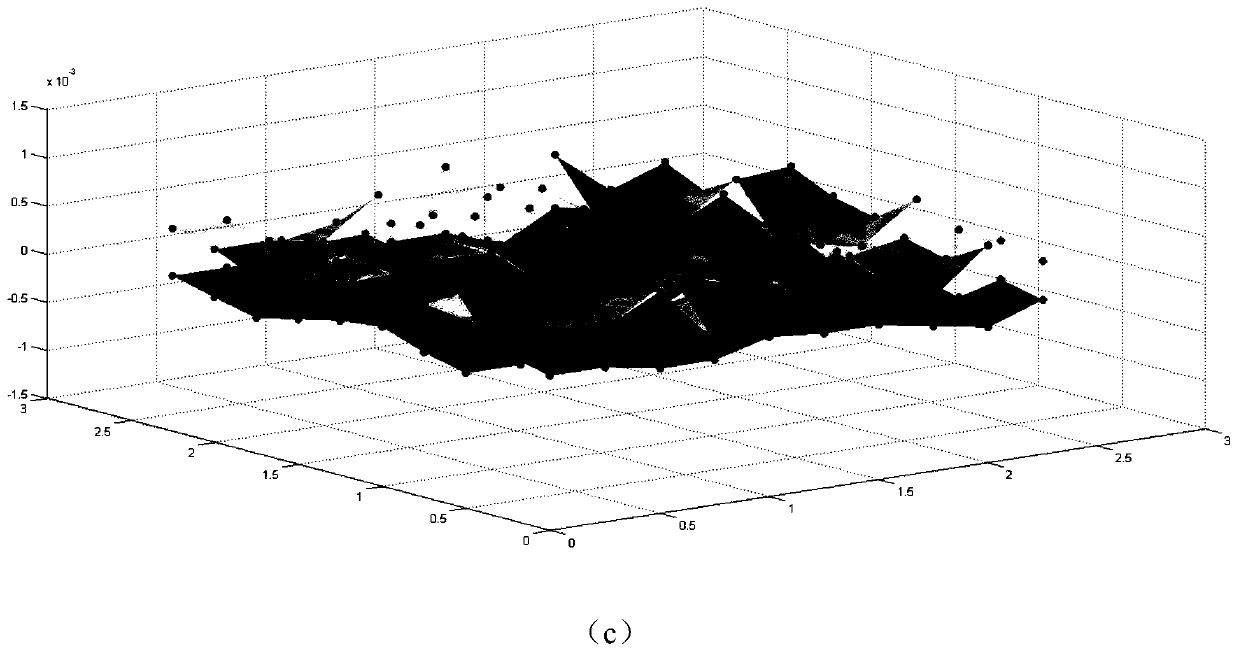

[0040] Step 1, place the coordinates of the measured points in the mating surface A and mating surface B in the same three-dimensional rectangular coordinate system, and require the assembly path to be parallel to the Z axis (such as figure 2 shown), and then calculate the shortest distance d between the matching surface A and the matching surface B by solving the algorithm of the minimum translation distance. First, through the coordinate transformation formula Place the mating surface A and the mating surface B in the same rectangular coordinate system according to the relative position in the actual assembly process, the assembly path is parallel to the Z axis, and it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com