Axial fuel shuffling metal cooled reactor and management method

A reactor and material metal technology, applied in the direction of reactors, reactor fuel elements, nuclear reaction control, etc., can solve the problem of uneven distribution of axial burnup in liquid metal cooling reactors, and increase the average unloading burnup depth, three-dimensional power Effect of flat distribution and fuel consumption distribution and reduction of power share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

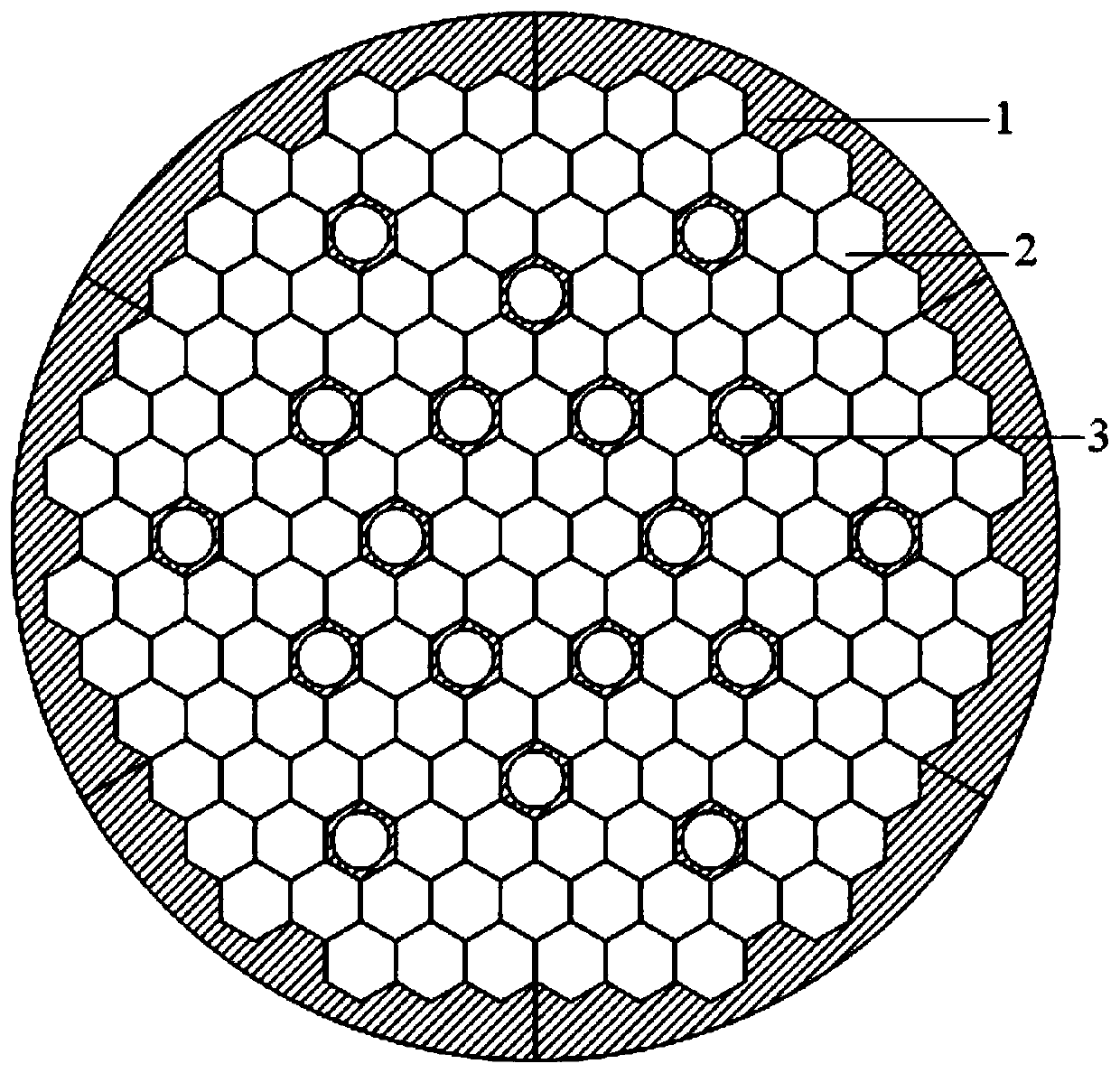

Embodiment 1

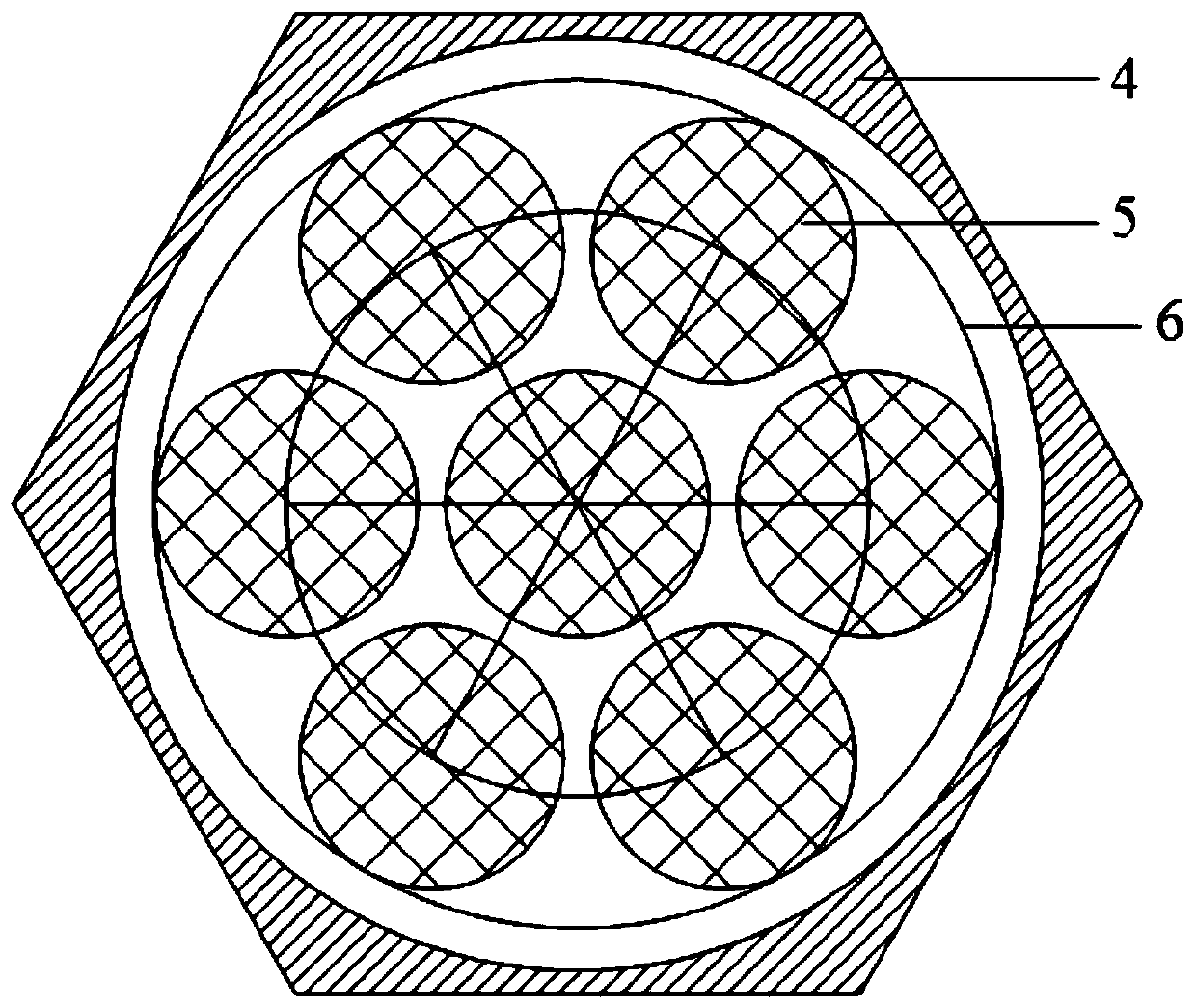

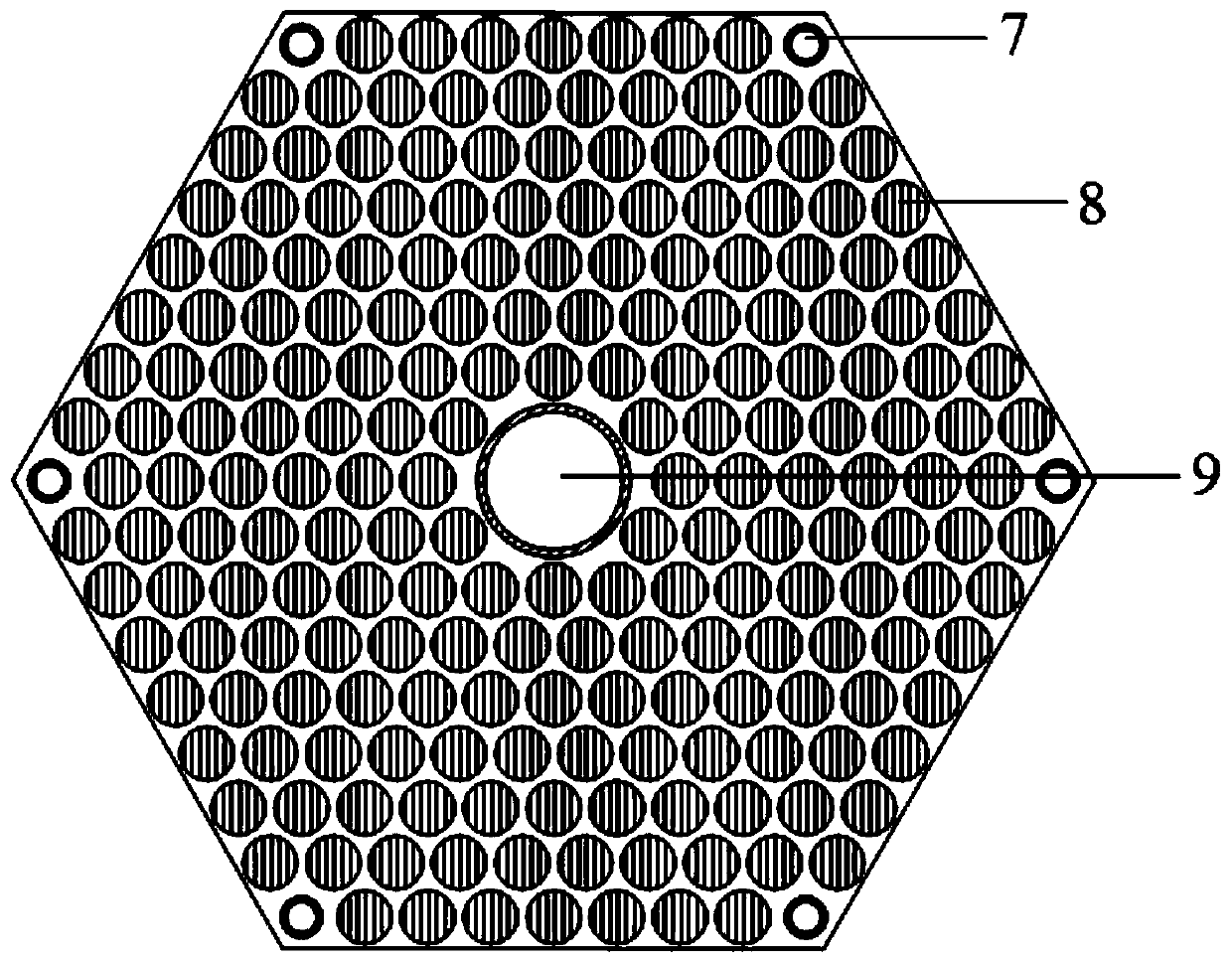

[0024] Such as Figure 1-Figure 4 As shown, a kind of axial refueling metal cooling reactor, the core structure of the reactor is an integral honeycomb regular hexagonal assembly channel, which contains 163 regular hexagonal channels, including 145 fuel assembly channels 2 and 18 The channel 3 of the control rod assembly, and the exterior of the core is an integral metal reflective layer 1 . The guide tube 4 of the control rod assembly with the shape of "square outside and circle inside" is arranged in the channel 3 of the control rod assembly, and the inner diameter is 125 mm. The distance between the centers of adjacent hexagonal channels is 139 mm, and the wall thicknesses of the fuel assembly channel 2 and the control rod assembly channel 3 are both 2.0 mm. The fuel assembly channel 2 is provided with 3 boxes of fuel assemblies 10 in the axial direction; the outer side of the integral honeycomb regular hexagonal assembly channel is provided with an integral metal reflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com