Dish-washing machine spraying assemblies and dish-washing machine

A technology for spraying components and dishwashers, which is applied to the washing machine/washing machine for tableware, parts of the washing machine/rinsing machine for tableware, cleaning equipment, etc. The problem of small and uneven washing water consumption can achieve the effect of improving convenience, convenient loading and unloading, and optimizing the sealing structure and rotating positioning structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

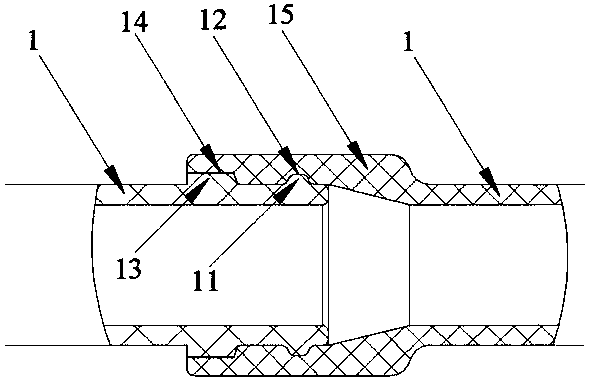

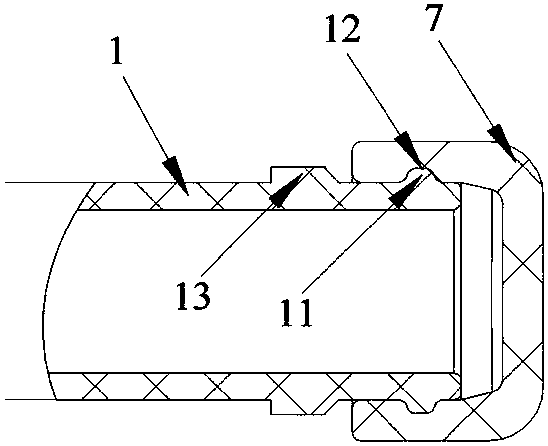

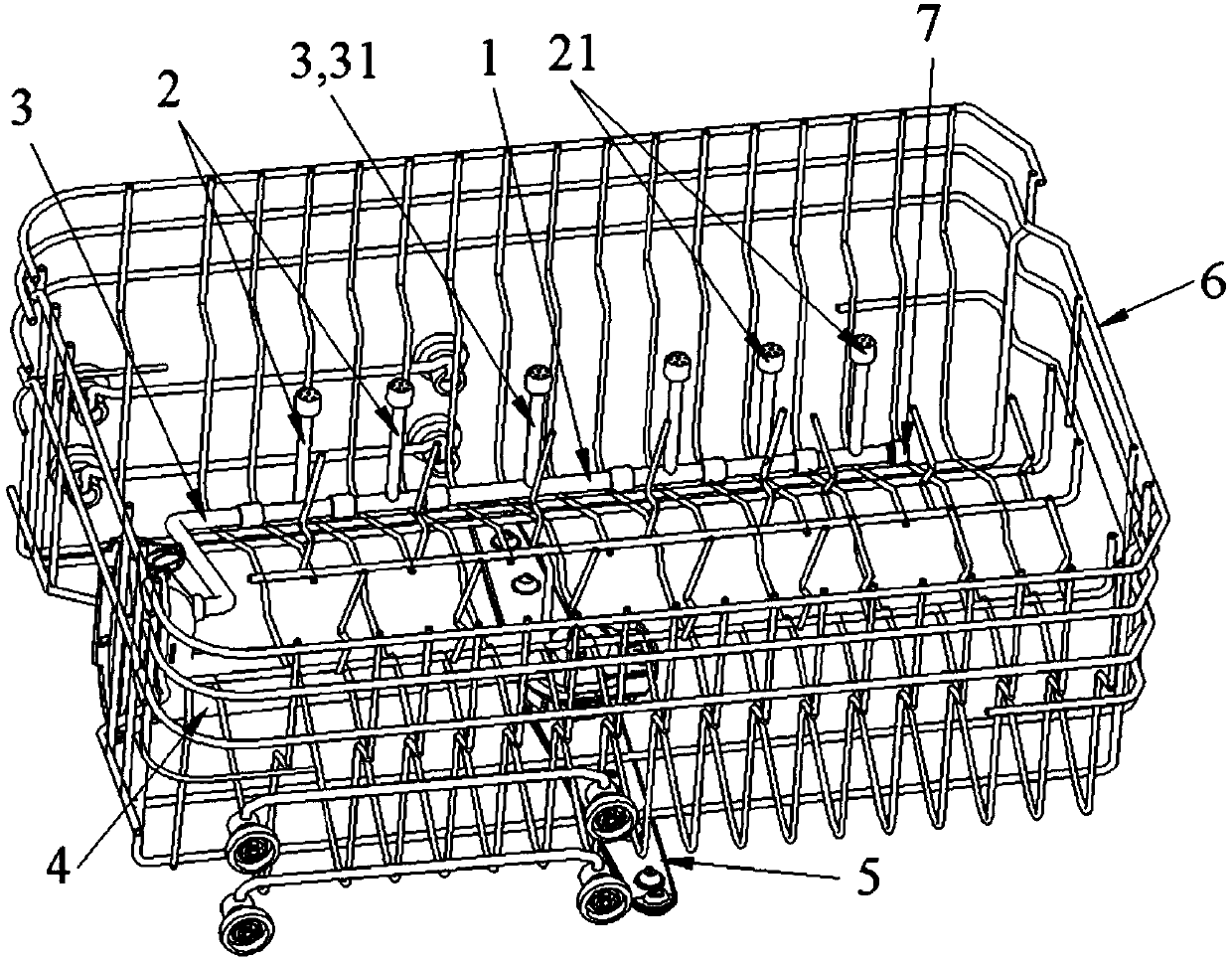

[0050] In this example, if Figure 1~6 As shown, a dishwasher spray assembly is provided. The dishwasher includes a rack 6 and an auxiliary water guide pipe 3 located in the rack 6. The auxiliary water guide pipe 3 includes a number of sprayers connected in sequence and with adjustable spray angles. Component 31 guides the water flow to flush the containers on the shelf 6 .

[0051] In this embodiment, the auxiliary water diversion pipe 3 includes several spray assemblies 31 connected in sequence, so that each sprinkler assembly 31 forms a part of the auxiliary water diversion pipe 3, and the user can adjust the rotation of each spray assembly 31 in the axial direction. The angle is adjusted and then connected and assembled, so that the spray assembly 31 is limited by the positioning structure, and sprays according to the adjusted angle, so as to realize multi-angle washing and washing of the tableware placed in the shelf 6 . In addition, the user can determine the number of ...

Embodiment 2

[0074] The difference between this embodiment and embodiment 1 is:

[0075] In this embodiment, the distances between the spray pipes 2 are set differently for users to place containers of various sizes; wherein, the distance between at least one spray pipe 2 and the adjacent spray pipes 2 on both sides is greater than that of other spray pipes 2 the distance between.

[0076] In this embodiment, each spray assembly 31 is provided with a plurality of spray pipes 2 respectively, so that several spray pipes 2 are distributed on each spray assembly 31 connected in sequence, and the spray assembly of different specifications can be changed. The distance between adjacent spray pipes 2 is suitable for containers of different sizes. For example, if the tableware to be washed is a small-mouthed deep cup with a larger diameter, the spray pipe with a larger distance from the adjacent spray pipe 2 can be selected. Tube 2 for standing wash.

[0077] In this example, if Figure 8 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com