Self-checking system of door sliding block

A technology of self-inspection system and slider, which is applied in elevators, elevators in buildings, transportation and packaging, etc. It can solve problems such as falling down the shaft, closing the landing door in place, and wearing out the wear-resistant material of the door slider, and achieves a simple structure. , No noise nuisance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

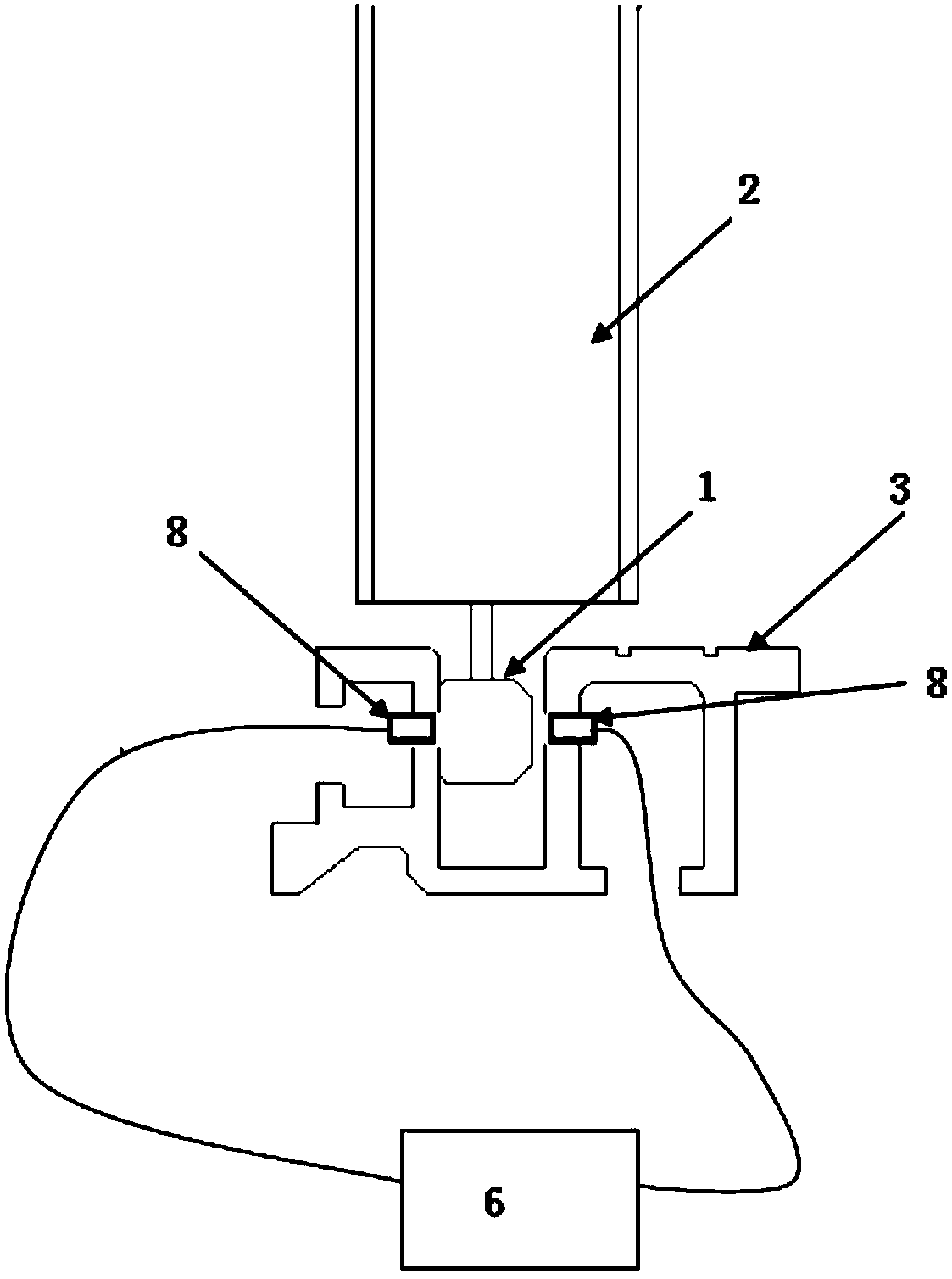

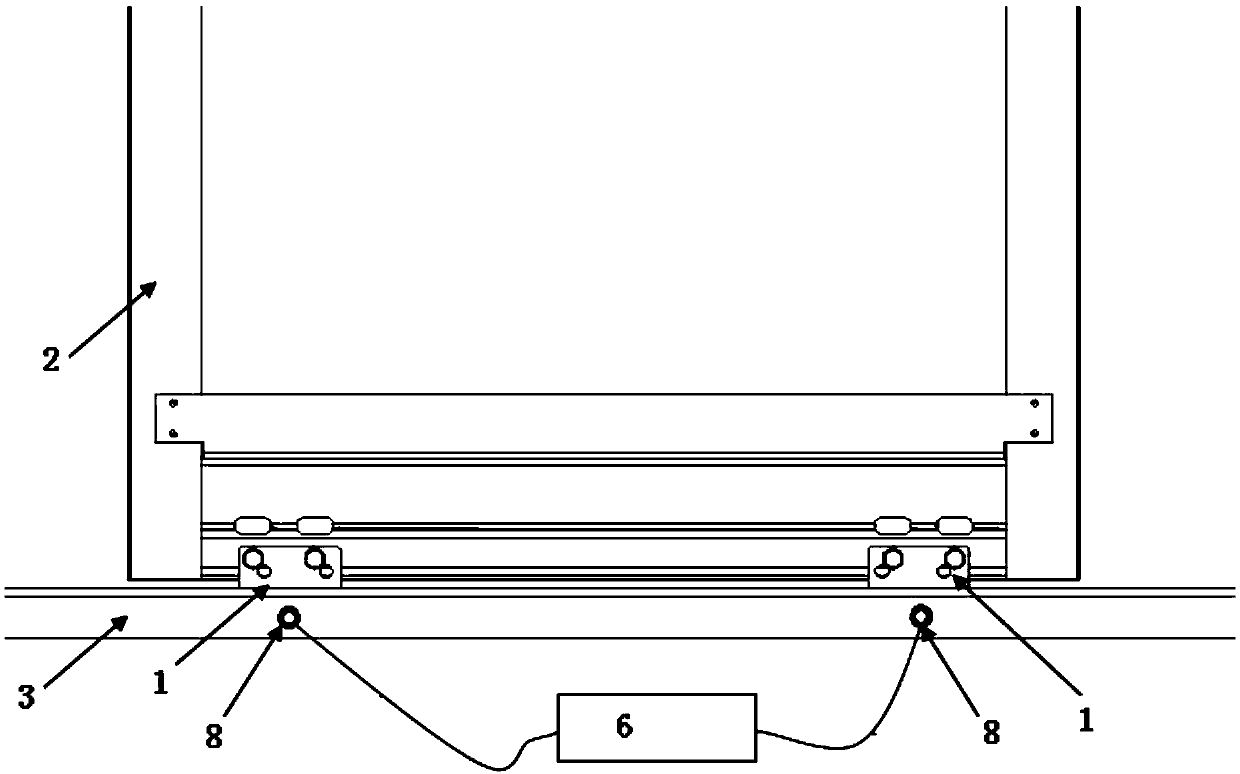

[0068] Such as figure 1 , figure 2 As shown, the door slider self-inspection system includes an elevator door 2, a door slider 1, a sill groove 3, a reflective photoelectric device 8, and a controller 6;

[0069] The upper end of the door slider 1 is fixedly connected to the bottom of the elevator door 2;

[0070] The door slider 1 penetrates into the sill groove 3, and slides in the sill groove 3 with the opening and closing of the elevator door 2;

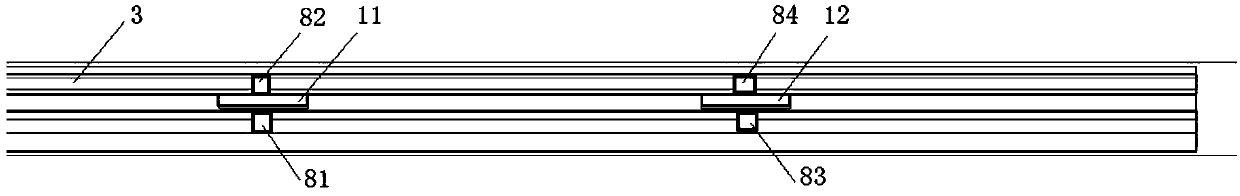

[0071] The wear-resistant surface of the door slider facing the friction surface of the sill groove 3 of the door slider 1 has a double-layer structure, the inner layer of the wear-resistant surface of the door slider can reflect specific light waves, and the outer layer cannot reflect specific light waves;

[0072] The friction surface of the sill groove 3 cannot reflect specific light waves;

[0073] The friction surface of the sill groove 3 is perforated, and a reflective photoelectric device 8 is embedded; the door slider...

Embodiment 2

[0080] Based on the door slider self-inspection system of Embodiment 1, the specific light wave is infrared light, the inner layer of the wear-resistant surface of the door slider is made of a material that can reflect infrared light, and the outer layer is made of a material that cannot reflect infrared light;

[0081] Preferably, the material that can reflect infrared light is silver, and the material that cannot reflect infrared light is carbon black, dark green or red.

[0082] Preferably, the thickness of the inner layer of the wear-resistant surface of the door slider is 0.15 mm to 0.25 mm (eg 0.2 mm), and the thickness of the outer layer is 0.45 mm to 0.55 mm (eg 0.5 mm).

[0083] Preferably, the first signal is at a high level (eg 5V), and the second signal is at a low level (eg 0V).

[0084] In the door slider self-inspection system of Embodiment 2, after the door slider is severely worn, the outer layer of the wear-resistant surface of the door slider can absorb infr...

Embodiment 3

[0086] In the door slider self-inspection system of Embodiment 1, the two friction surfaces at the same position of the sill groove 3 have holes, and reflective photoelectric devices 8 are respectively embedded.

[0087] Preferably, when the elevator door is fully closed, a door slider is located between two reflective photoelectric devices 8, wherein one reflective photoelectric device 8 faces the front of the door slider, and the other reflective photoelectric device 8 faces the front of the door slider. Opposite side of door slider.

[0088] In the door slider self-inspection system of Embodiment 3, the number of reflective photoelectric devices 8 is two, one facing the front of the door slider, and the other facing the back of the door slider. If the front side of the door slider is worn out for a long time, and the wear amount on the back side is small, when the controller outputs too many signals of excessive wear of the front door slider, it can be concluded that there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com