Method and device for purifying electrolyte of flow battery

A purification method and flow battery technology, applied in fuel cells, electrolyte flow treatment, regeneration fuel cells, etc., can solve the problems of cumbersome process, difficult to remove a variety of metal ions at one time, difficult to remove, etc., to widen the selection range, The effect of simple and easy-to-operate recovery of metallic mercury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0039] In the first embodiment of the present invention, a method for purifying the electrolyte of a flow battery is provided, which is characterized in that it includes the following steps:

[0040] Steps for providing an electrolytic cell having an anode, an anolyte, a cathode, and a membrane:

[0041] passing the electrolyte to be purified over the surface of the cathode;

[0042] Wherein, the cathode is metal mercury, and when the electrolytic solution to be purified passes through the surface of the cathode, a reduction reaction occurs at least in a part of the surface area of the cathode under the action of an external current.

[0043] anode and anolyte

[0044] In an embodiment of the invention, the anode comprises an anode material. The anode material may include a carbon-based material having a porous structure, and the pores can form a communication structure that accommodates or allows the electrolyte to flow. The porous structure can be formed by a foaming ...

no. 2 approach

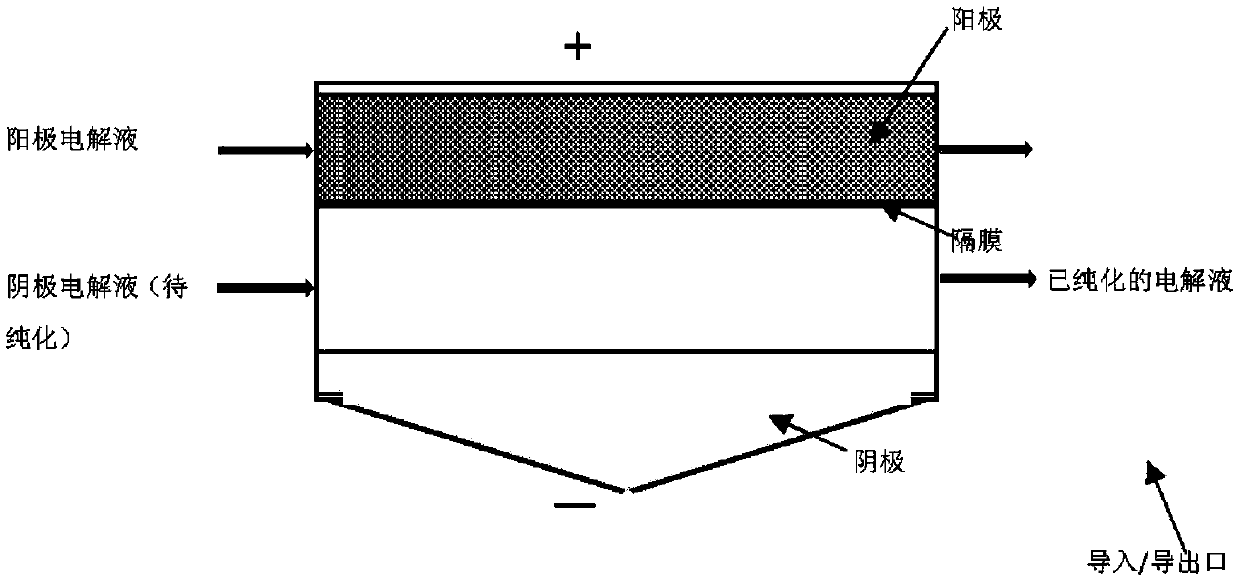

[0056] The second embodiment of the present invention relates to a purification device for electrolyte of a flow battery, which includes the following structure:

[0057] Cell;

[0058] Cathode material import / export,

[0059] Wherein, the electrolytic cell includes an anode, a cathode and a diaphragm,

[0060] the cathode is metallic mercury, and

[0061] A space is formed between the cathode surface and the separator, which space is able to accommodate the electrolyte to be purified or to allow the passage of the electrolyte to be purified.

[0062] The electrolytic cell is divided by a diaphragm into an anode part and a cathode part, and the anode part includes an anode material which is the same as that in the first embodiment of the present invention.

[0063] The cathode portion includes a cathode and a space formed between a separator and the cathode. The separator and cathode are the same as described in the first embodiment of the present invention. The space for...

Embodiment

[0093] Inject 2.5mol / L of V at a flow rate of 5L / min 3+ / V 2+ 100L hydrochloric acid solution, make it flow through the anode of the electrolytic cell composed of graphite felt and graphite bipolar plate; pass 2.5mol / L V at a flow rate of 5L / min 3+ / V 4+ Mix 100L of hydrochloric acid solution and make it flow through the cathode of the electrolytic cell composed of cavity and metal mercury, in which Ag + The content is 150ppm, Au + The content is 80ppm, Pt + The content is 20ppm, Cu 2+ The content is 200ppm. Apply 40mA / cm to the electrolytic cell 2 current, so that the anode V 2+ An oxidation reaction occurs, and a reduction reaction occurs on impurity metal ions at the cathode. A pump is used to circulate the electrolyte of the anode and cathode through the electrolytic cell five times to achieve the purpose of removing impurity metal ions to the greatest extent. The content of each impurity in the purified catholyte is lower than 1ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com