Method for improving sintering activity of cerium oxide doped electrolyte

A technology for sintering activity and cerium oxide, which is applied in the field of improving the sintering activity of doped cerium oxide electrolytes, can solve the problems of sintering obstacles, obstacles, and difficulty in promoting the transport of cerium oxide materials, and achieves the effect of improving electrical conductivity and expanding the selection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

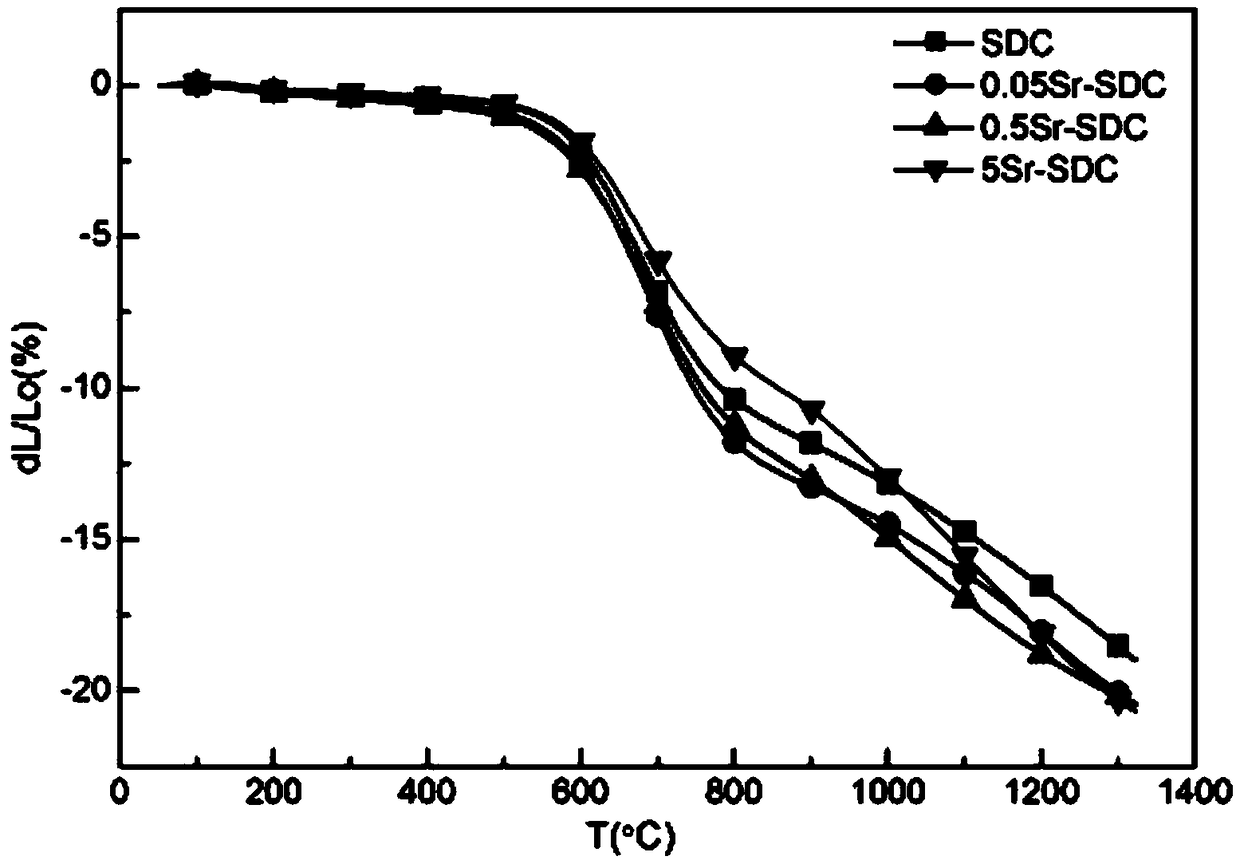

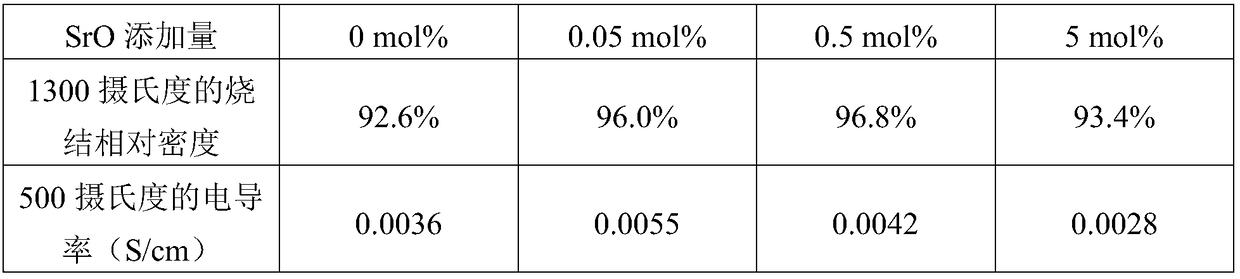

[0022] Preparation of Ce with 0.05 mol% SrO sintering aid 0.8 SM 0.2 o 1.9 electrolyte material.

[0023] First, weigh 347.378g of Ce(NO 3 ) 3 ·6H 2 O, 88.893g of Sm(NO 3 ) 3 ·6H 2 O, 0.106g of Sr(NO 3 ) 2 , dissolved in deionized water, and prepared as a metal ion solution with a concentration of 1mol / L in a 1L volumetric flask.

[0024] Then, weigh 124.10g of (NH 4 ) 2 C 2 o 4 , dissolved in deionized water, and prepared as a 1mol / L ammonium oxalate solution in a 1L volumetric flask.

[0025] Then, take 100ml of the above-mentioned metal ion solution, drop it into 500ml of the above-mentioned ammonium oxalate solution in a stirred state, and carry out co-precipitation, and use ammonia water to control the pH value between 6.5 and 6.8 during the precipitation reaction.

[0026] Then, the composite powder obtained by the co-precipitation is centrifuged from the solution, and the precipitate is taken out, washed with deionized water and ethanol to obtain a precur...

Embodiment 2

[0030] Preparation of Ce with 0.5 mol% SrO sintering aid 0.8 SM 0.2 o 1.9 electrolyte material.

[0031] First, weigh 347.378g of Ce(NO 3 ) 3 ·6H 2 O, 88.893g of Sm(NO 3 ) 3 ·6H 2 O, 1.058g of Sr(NO 3 ) 2, dissolved in deionized water, and prepared as a metal ion solution with a concentration of 1mol / L in a 1L volumetric flask.

[0032] Then, weigh 124.10g of (NH 4 ) 2 C 2 o 4 , dissolved in deionized water, and prepared as a 1mol / L ammonium oxalate solution in a 1L volumetric flask.

[0033] Then, take 100ml of the above-mentioned metal ion solution, drop it into 500ml of the above-mentioned ammonium oxalate solution in a stirred state, and carry out co-precipitation, and use ammonia water to control the pH value between 6.5 and 6.8 during the precipitation reaction.

[0034] Then, the composite powder obtained by the co-precipitation is centrifuged from the solution, and the precipitate is taken out, washed with deionized water and ethanol to obtain a precurso...

Embodiment 3

[0038] Preparation of Ce with 5 mol% SrO sintering aid 0.8 SM 0.2 o 1.9 electrolyte material.

[0039] First, weigh 347.378g of Ce(NO 3 ) 3 ·6H 2 O, 88.893g of Sm(NO 3 ) 3 ·6H 2 O, 10.581g of Sr(NO 3 ) 2 , dissolved in deionized water, and prepared as a metal ion solution with a concentration of 1mol / L in a 1L volumetric flask.

[0040] Then, weigh 124.10g of (NH 4 ) 2 C 2 o 4 , dissolved in deionized water, and prepared as a 1mol / L ammonium oxalate solution in a 1L volumetric flask.

[0041] Then, take 100ml of the above-mentioned metal ion solution, drop it into 500ml of the above-mentioned ammonium oxalate solution in a stirred state, and carry out co-precipitation, and use ammonia water to control the pH value between 6.5 and 6.8 during the precipitation reaction.

[0042] Then, the composite powder obtained by the co-precipitation is centrifuged from the solution, and the precipitate is taken out, washed with deionized water and ethanol to obtain a precurso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com