Efficient ejector

An ejector and high-efficiency technology, which can be used in ejection devices, liquid ejection devices, etc., can solve the problems of generating eddy currents, shock waves, eddy currents, etc., and achieve the effects of smooth velocity gradient changes, reduced energy loss, and smooth velocity changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

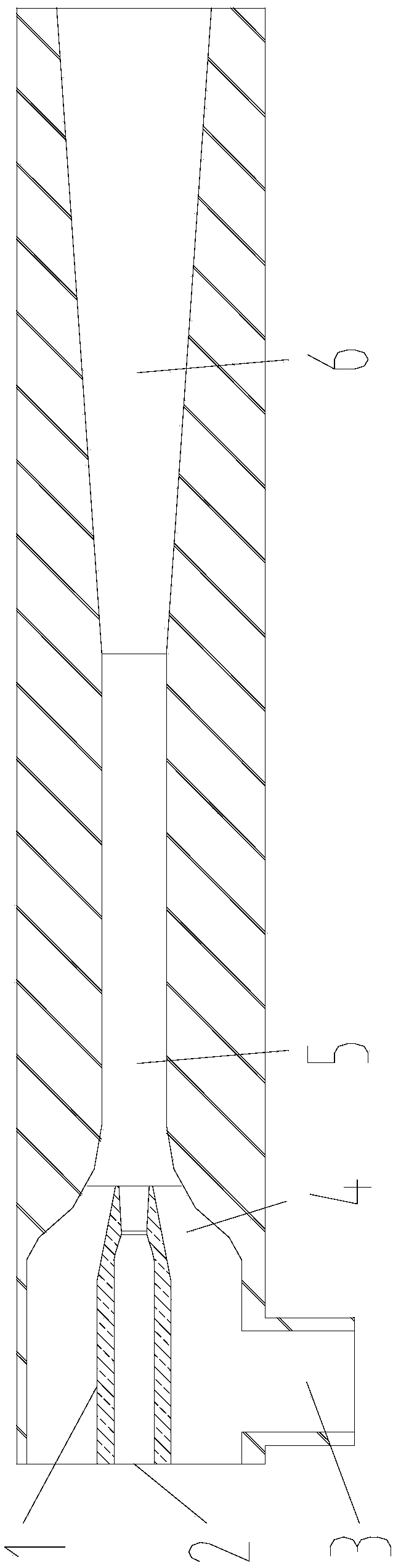

[0032] Such as figure 1 As shown, the high-efficiency injector of this embodiment includes: a working nozzle 1 , a working fluid inlet 2 , an injection fluid inlet 3 , a receiving chamber 4 , a mixing chamber 5 and a diffusion chamber 6 .

[0033] The working nozzle 1 communicates with the working fluid inlet 2 , the injection fluid inlet 3 communicates with the receiving chamber 4 , the working nozzle 1 and the receiving chamber 4 communicate with the mixing chamber 5 , and the mixing chamber 5 communicates with the diffusion chamber 6 .

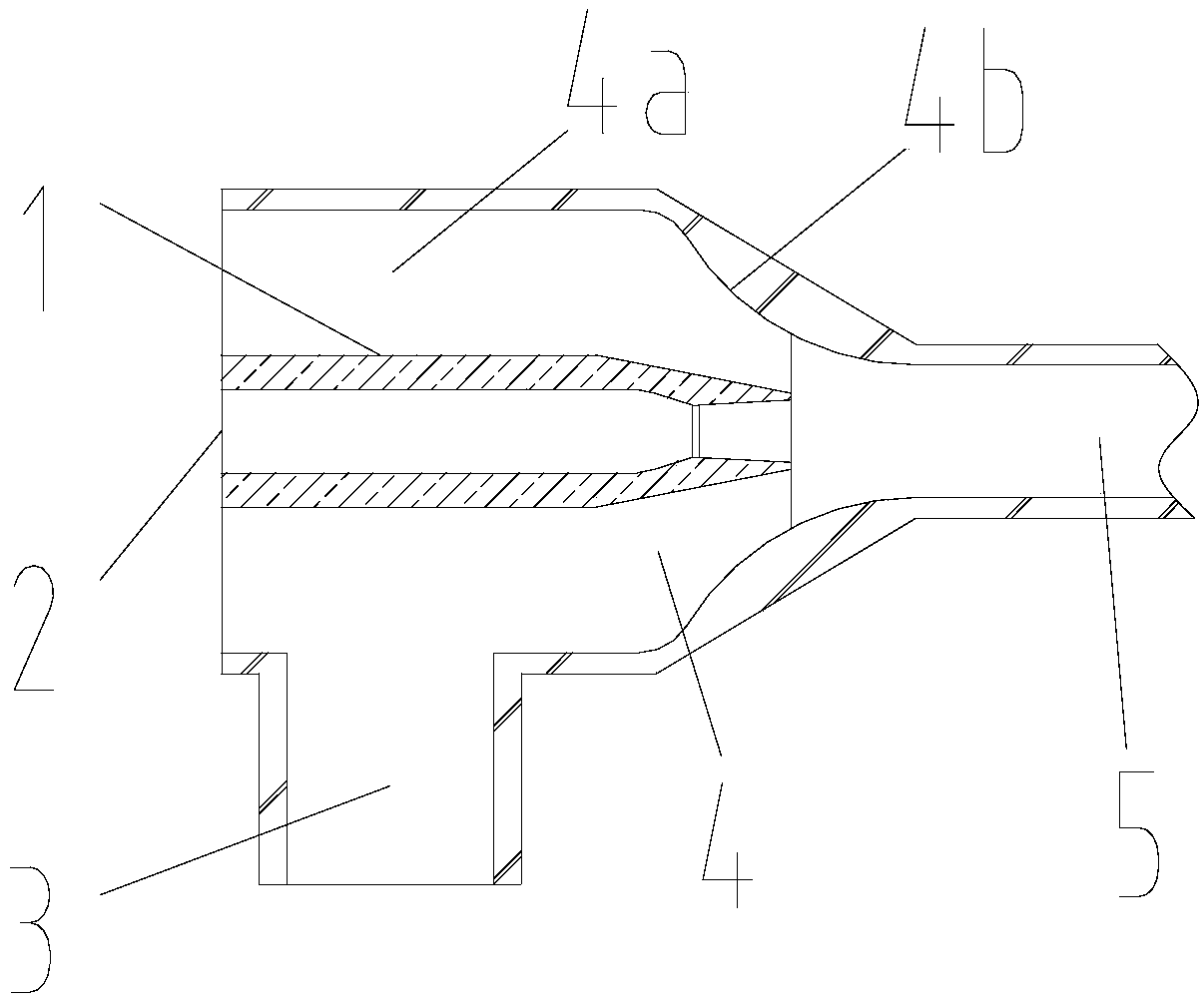

[0034] Such as figure 2 As shown, the receiving chamber 4 includes the body cavity 4a and the curve of the contracting section 4b of the receiving chamber connected to the body cavity 4a is designed according to the Witolshinski curve, so as to reduce the speed of the working fluid and the injection fluid when they are mixed. The energy loss caused by the difference.

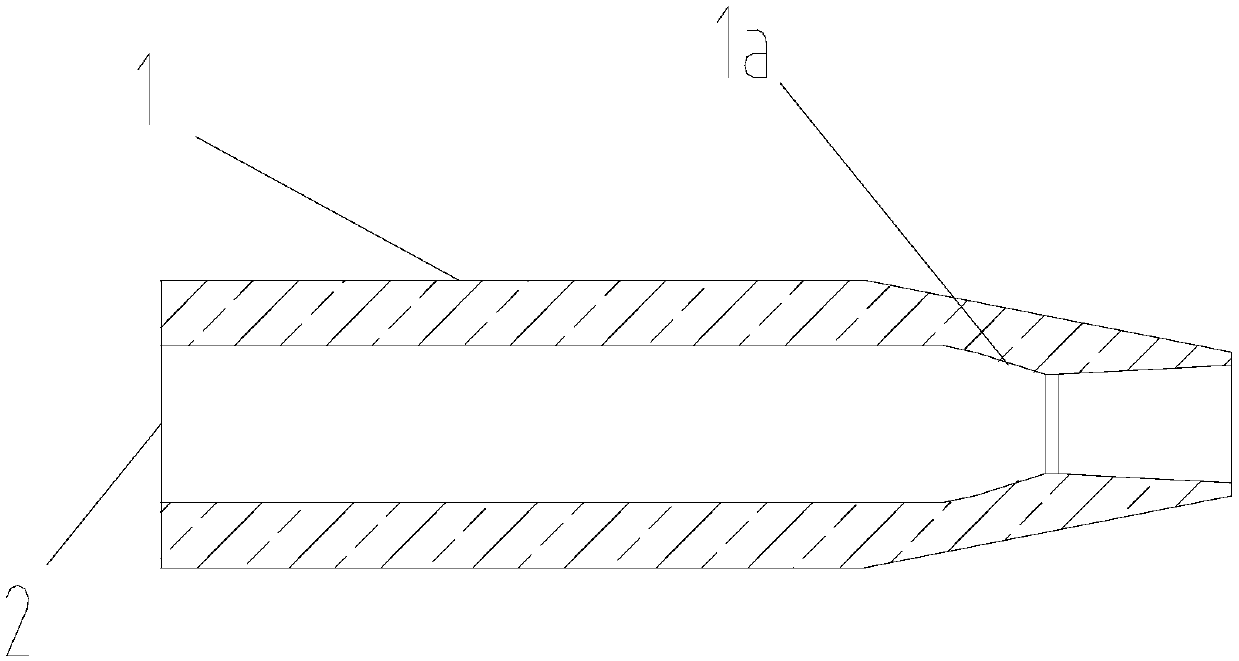

[0035] Such as image 3 As shown, the working nozzle 1 adopts a scal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com