Intelligent heat dissipation control method of multi-gun large-power direct current charging pile

A technology of DC charging piles and control methods, applied in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve the problems of high noise, unintelligent heat dissipation control of charging piles, and high energy consumption, so as to reduce energy consumption and reduce transformation costs cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manners of the present invention will be further elaborated below in conjunction with the accompanying drawings.

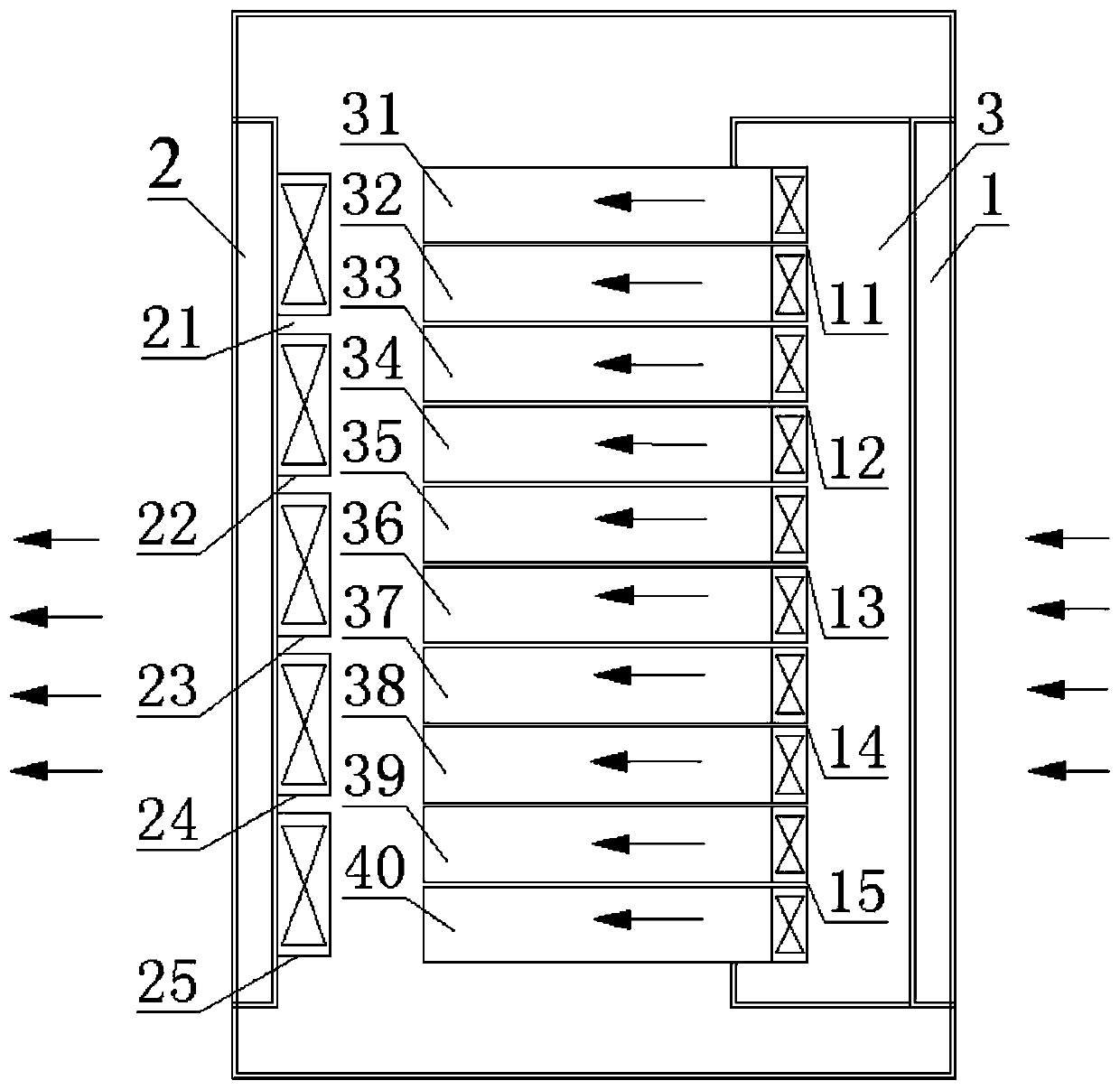

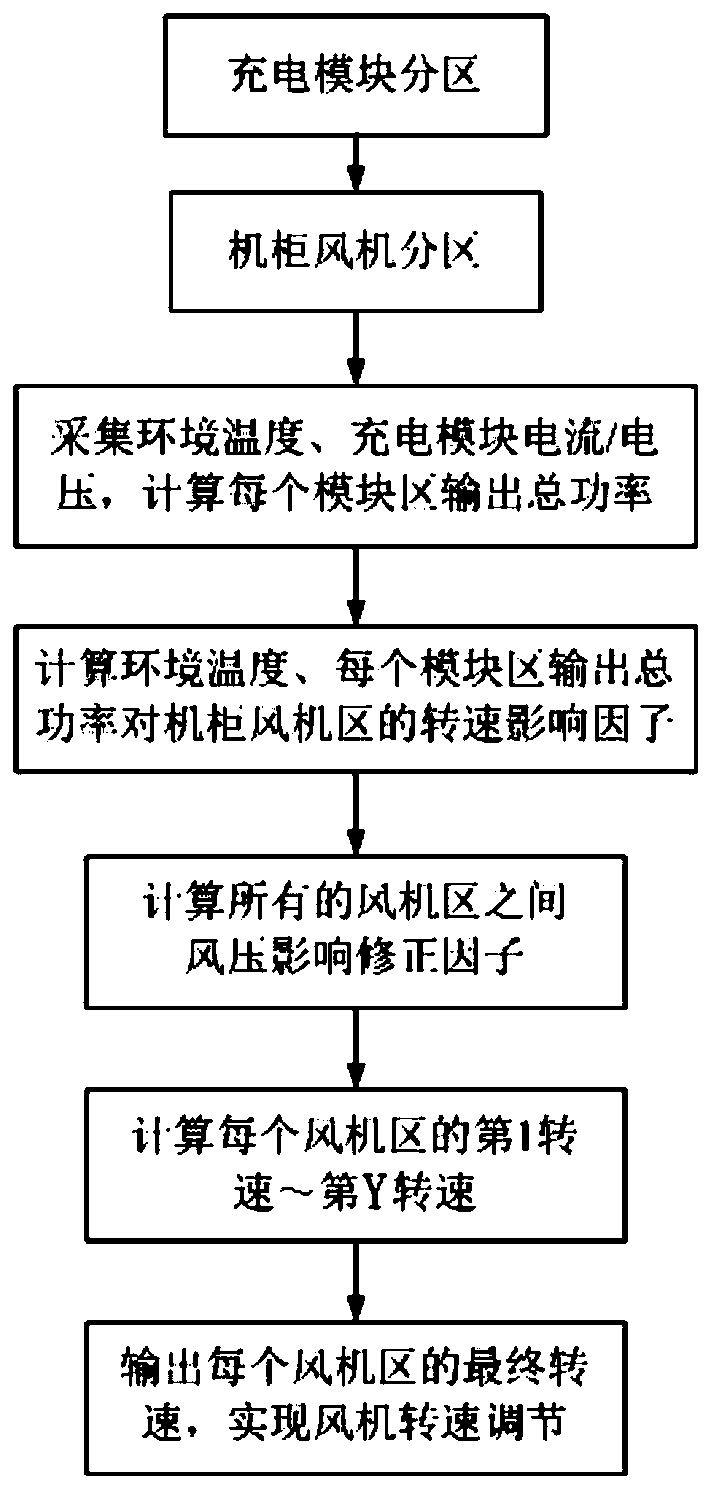

[0055] The heat dissipation system of the multi-gun high-power DC charging pile of the present invention is as follows: figure 1 As shown, the airflow direction inside and outside the cabinet is as follows: figure 1 As shown in the direction of the middle arrow, it includes the main control module and the cabinet body 3. On the right side of the cabinet body 3, there is an air inlet 1 (with a louver filter), and two sensors for detecting the ambient temperature are installed at the air inlet. It is connected to the main control module. There is an air outlet 2 (with louver filter) on the left side of the cabinet body 3. There are 5 cabinet fans of the same model at the air outlet 2. The charging pile is equipped with 5 charging guns (not in the figure 1 marked in ), there are 10 charging modules placed inside the cabinet (namely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com