Pressurized oxygen bag automatic assembling machine

An automatic assembly machine and oxygen bag technology, applied in metal processing, conveyor objects, transportation and packaging, etc., can solve the problems of automatic assembly of pressurized oxygen bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

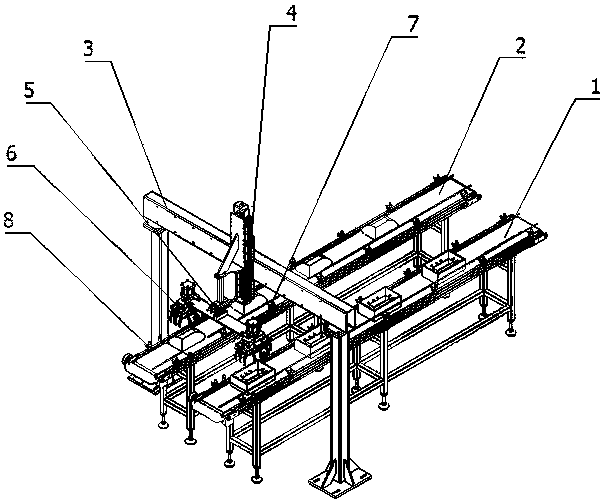

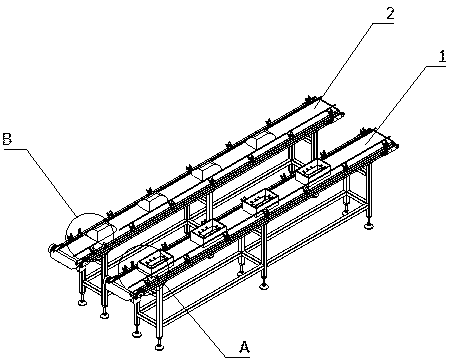

[0041] refer to Figure 2 to Figure 11 A pressurized oxygen bag automatic assembly machine shown includes a first transmission mechanism 1, a second transmission mechanism 2, a gantry frame 3, a lifting mechanism 4, a turning mechanism 5, a first clamping mechanism 6 and a second clamping mechanism The take-up mechanism 7, the first transmission mechanism 1 and the second transmission mechanism 2 are arranged side by side in the same direction, the gantry 3 is arranged at one end of the first transmission mechanism 1 and the second transmission mechanism 2, and the lifting mechanism 4 is vertically arranged on the gantry 3 , the turning mechanism 5 is arranged on the lifting working end of the lifting mechanism 4, the first gripping mechanism 6 and the second gripping mechanism 7 are respectively arranged on both sides of the turning mechanism 5 working end, the first gripping mechanism 6 and the second gripping mechanism 7 are identical in structure, and the clamping working ...

specific Embodiment approach 2

[0062] The difference from Embodiment 1 is that the staff place the oxygen bag coaxially at the feed port of the first transmission mechanism 1, and place the pressurized box coaxially at the feed port of the second transmission mechanism 2, and clamp and The assembly process is opposite to that of the first embodiment, but produces the same assembly effect.

[0063] Working principle of the present invention:

[0064] In the first embodiment, the staff places a pressurized box coaxially at the feed port of the first transmission mechanism 1, and places an oxygen bag coaxially at the feed port of the second transport mechanism 2, and the pressurized box is sent to the first transmission At the assembly end of the mechanism 1, the oxygen bag is sent to the clamping end of the second transmission mechanism 2. Before the lifting mechanism 4 starts to work, the first clamping mechanism 6 and the second clamping mechanism 7 are suspended by the gantry 3 to the second clamping mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com