Prefabricated type external prestressed steel truss combination beam structure and construction method thereof

A technology of external prestressing and prestressing steel bars, which is applied in the direction of bridges, truss bridges, bridge parts, etc., can solve problems such as inability to bypass, and achieve the effects of reducing difficulty, improving force, improving quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

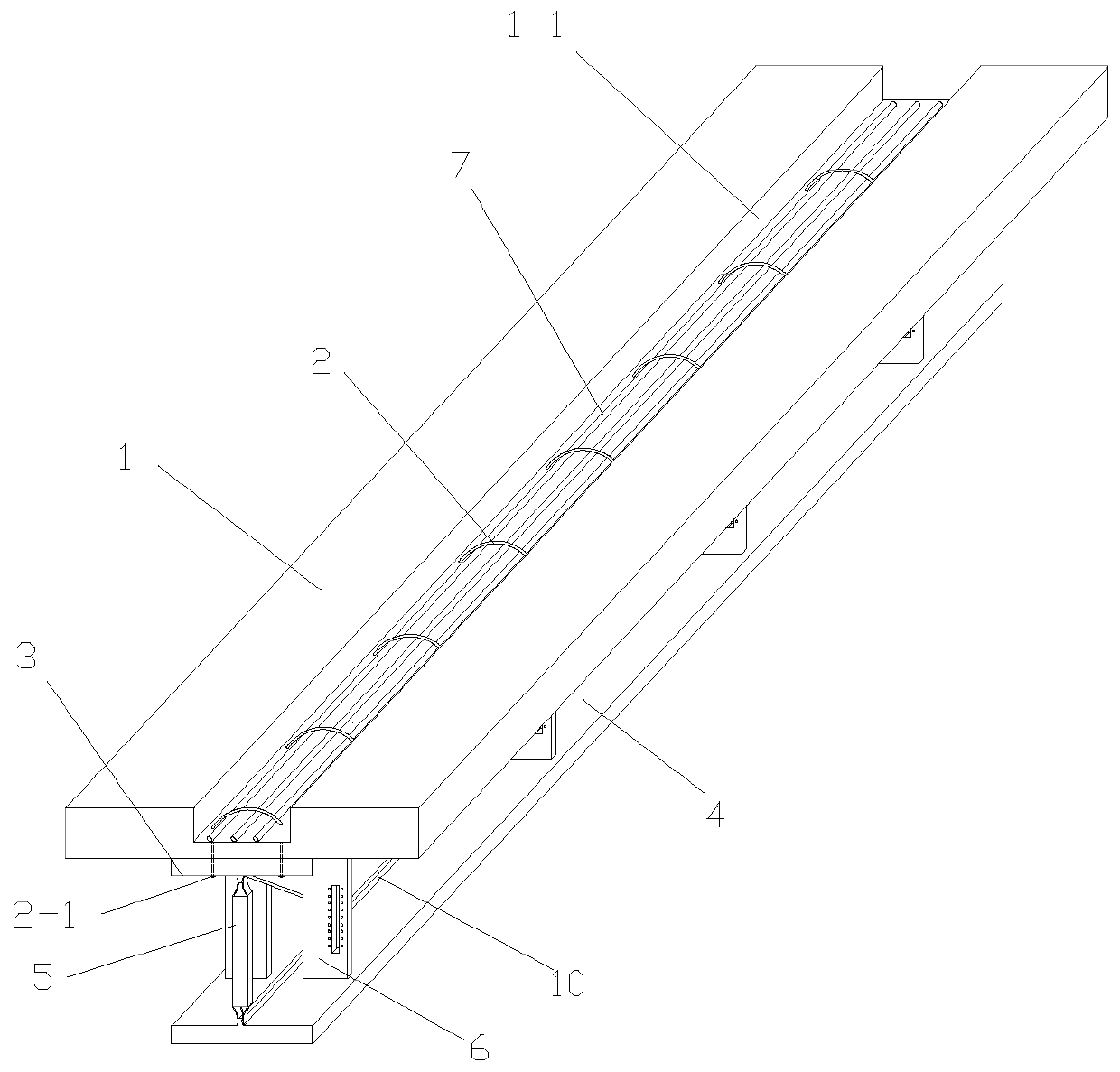

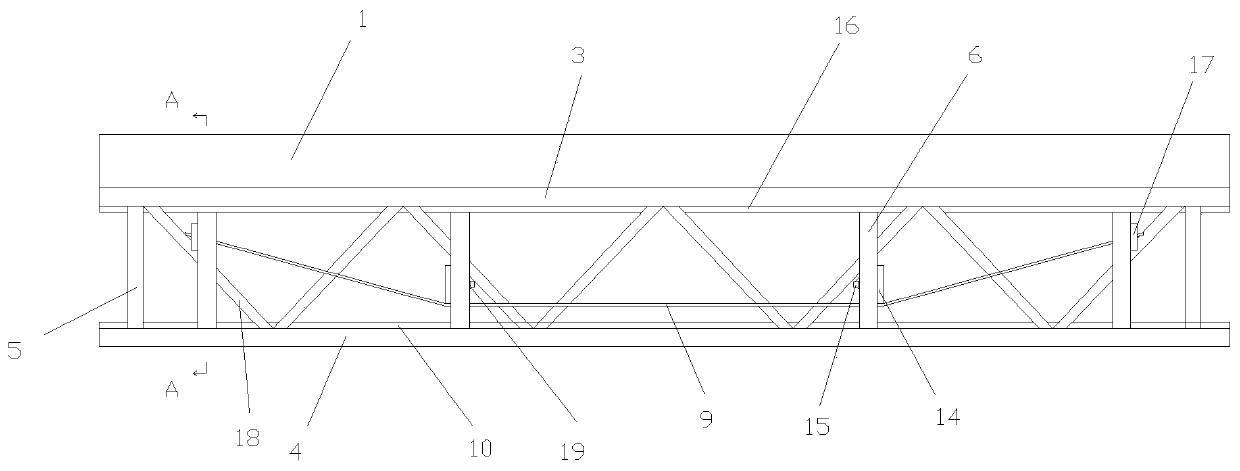

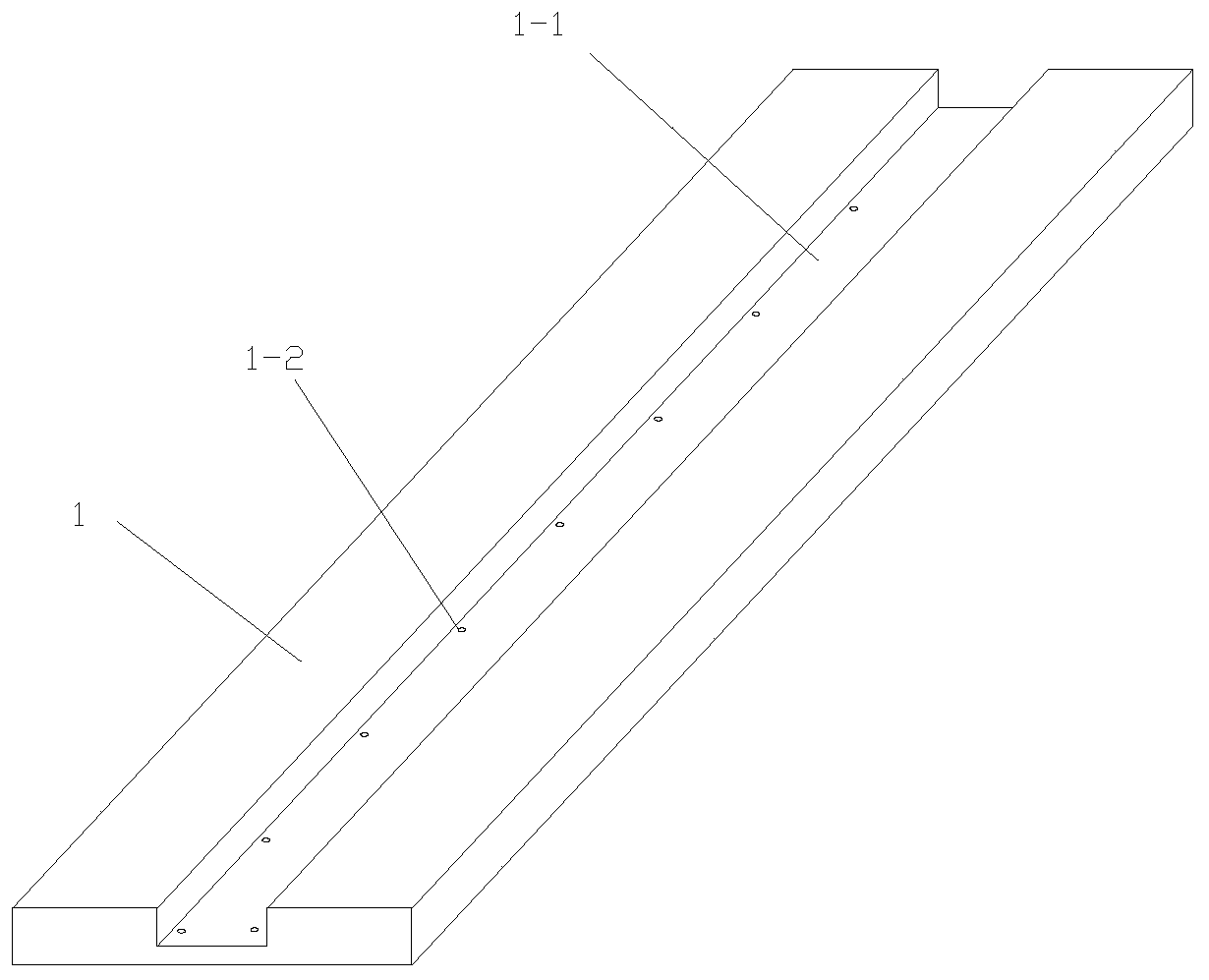

[0074] like figure 1 and figure 2 An assembled externally prestressed steel truss composite girder structure shown includes a plurality of bridge segments arranged from front to back along the longitudinal direction of the bridge. The structures of the multiple bridge segments are the same, and each of the bridge segments The above-mentioned bridge segments all include a concrete slab 1, a steel beam top plate 3, and a steel beam bottom plate 4 arranged sequentially from top to bottom. A truss mechanism and a support mechanism are arranged between the steel beam top plate 3 and the steel beam bottom plate 4. The truss mechanism includes two end steel chords 5 and a plurality of inclined steel chords 18 connected between the two end steel chords 5, and the two end steel chords 5 are symmetrically arranged on the steel beam roof 3 and the steel The two ends of the beam bottom plate 4, the support mechanism is located between the two end steel chords 5, and the prestressed stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com