Diversion sand bottom culvert system for rockfill concrete gravity dam

A rockfill concrete and gravity dam technology, applied in gravity dams, dams, barrages, etc., can solve problems such as increasing construction costs, prolonging construction periods, and reducing the structural stability of rockfill concrete gravity dams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

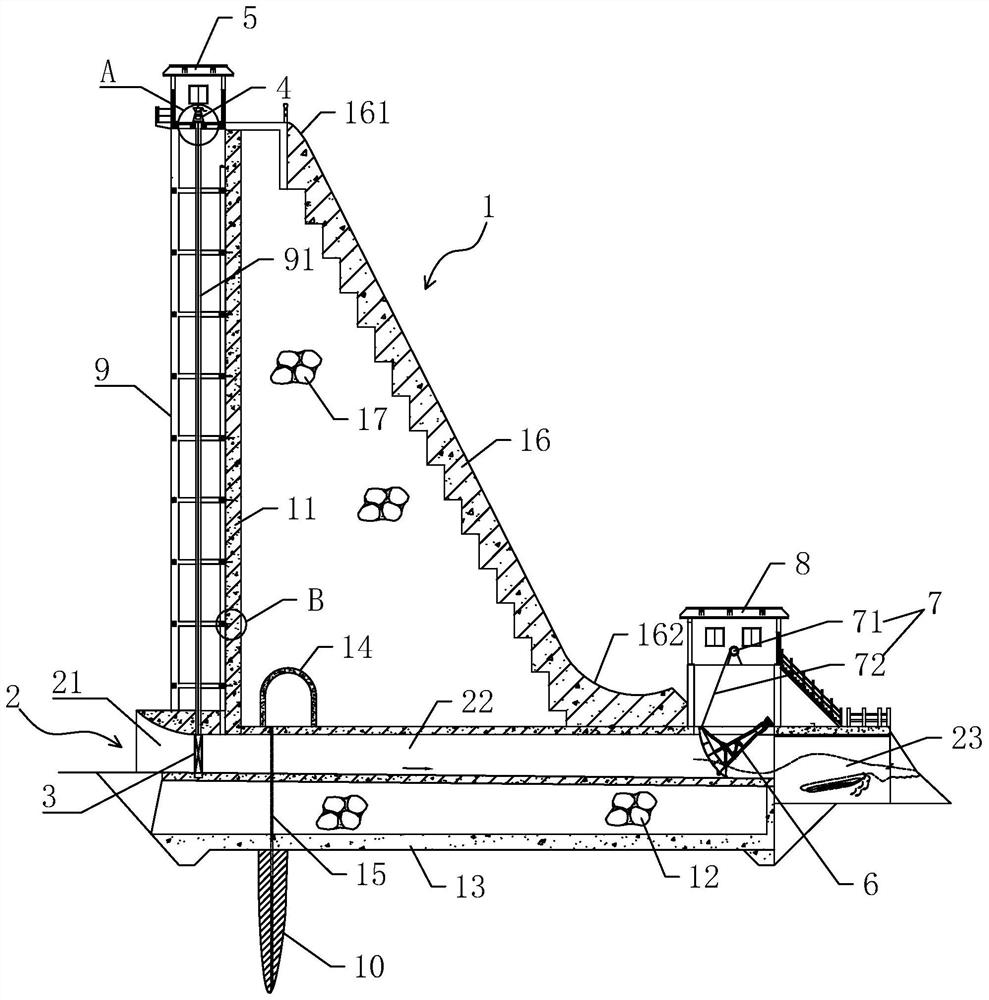

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

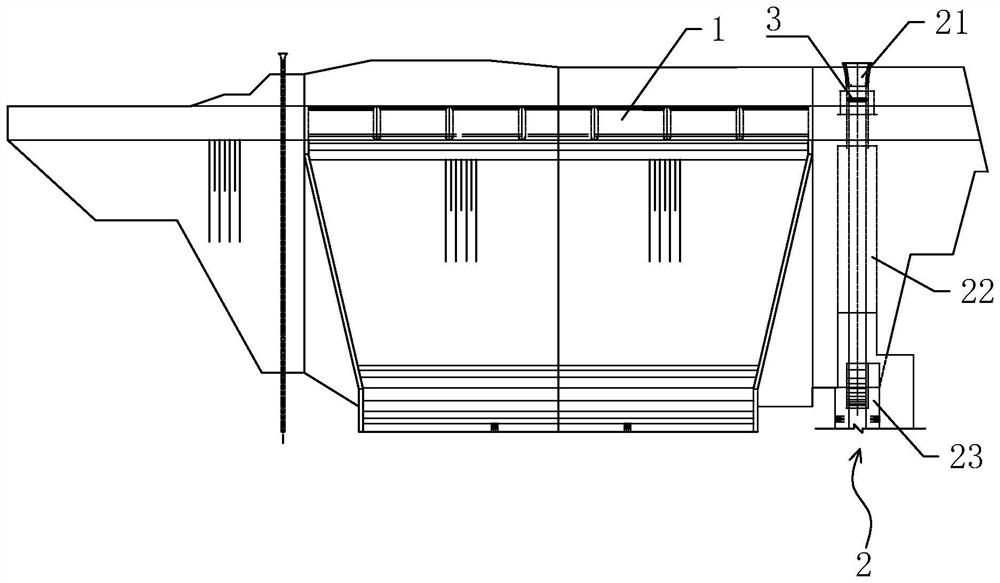

[0038] refer to figure 1 and figure 2 , is a rockfill concrete gravity dam diversion sand scouring bottom culvert system disclosed in the present invention, comprising: dam body 1, culvert hole 2, maintenance gate 3, first driving part 4, maintenance room 5, working gate 6, The second driving member 7, the working chamber 8.

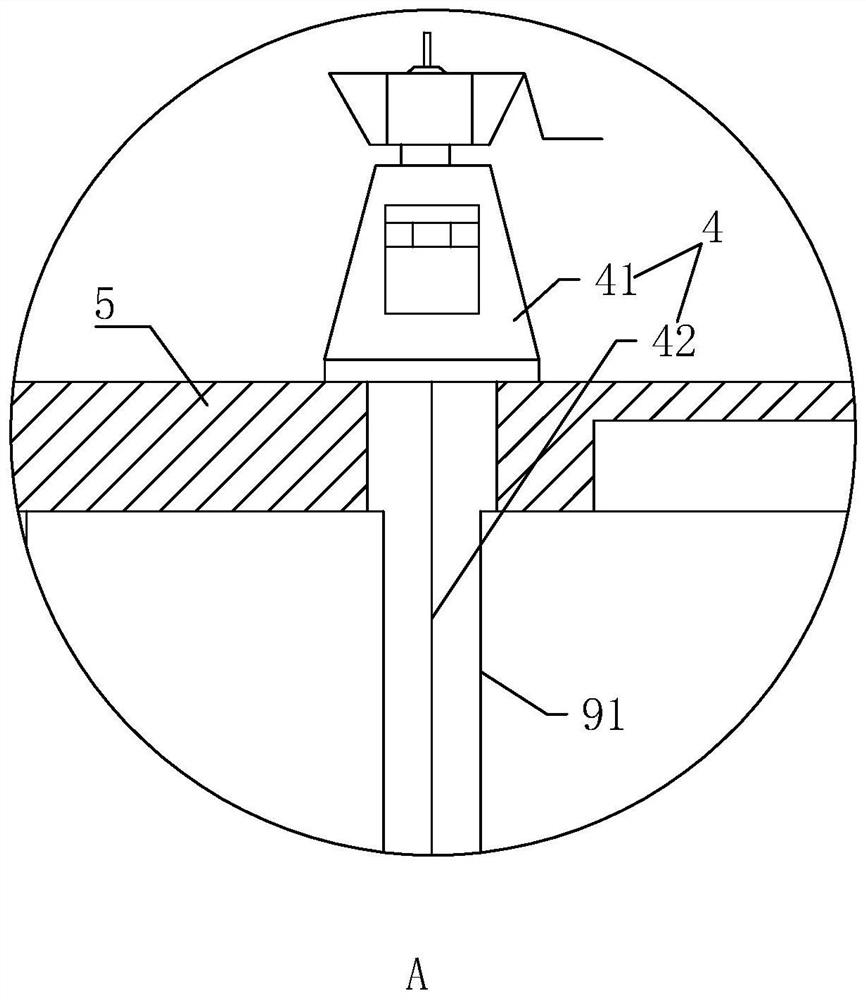

[0039] The culvert 2 is located at the bottom of one side of the dam body 1. The culvert 2 includes successively connected: an inlet section 21, a square culvert pipe section 22 and an outlet energy dissipation section 23. The inlet section 21 is vertically slidably equipped with a maintenance gate 3. A driver 4 is used to drive the inspection gate 3 to lift to open and close the inlet section 21. The top of the dam body 1 is provided with an inspection room 5, and the power part of the first driver 4 is arranged in the inspection ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com