Single-legged strip seam sound absorption structure

A slit and single-leg technology, which is applied in the direction of sound insulation, building components, building structures, etc., can solve the problems that the sound-absorbing effect of double-leg aluminum slit sound-absorbing panels needs to be improved, and the processing difficulty is reduced, so as to facilitate installation and disassembly, enhance Sound absorption effect, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

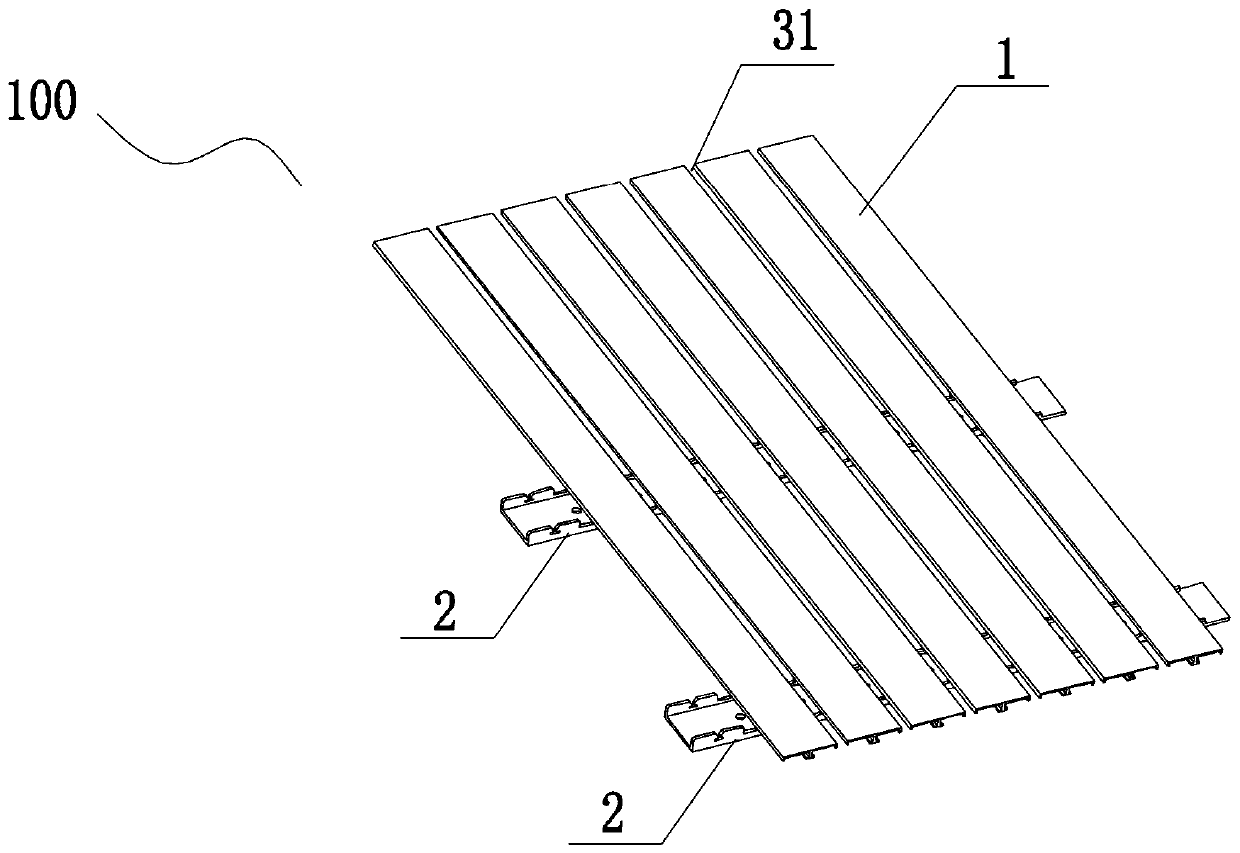

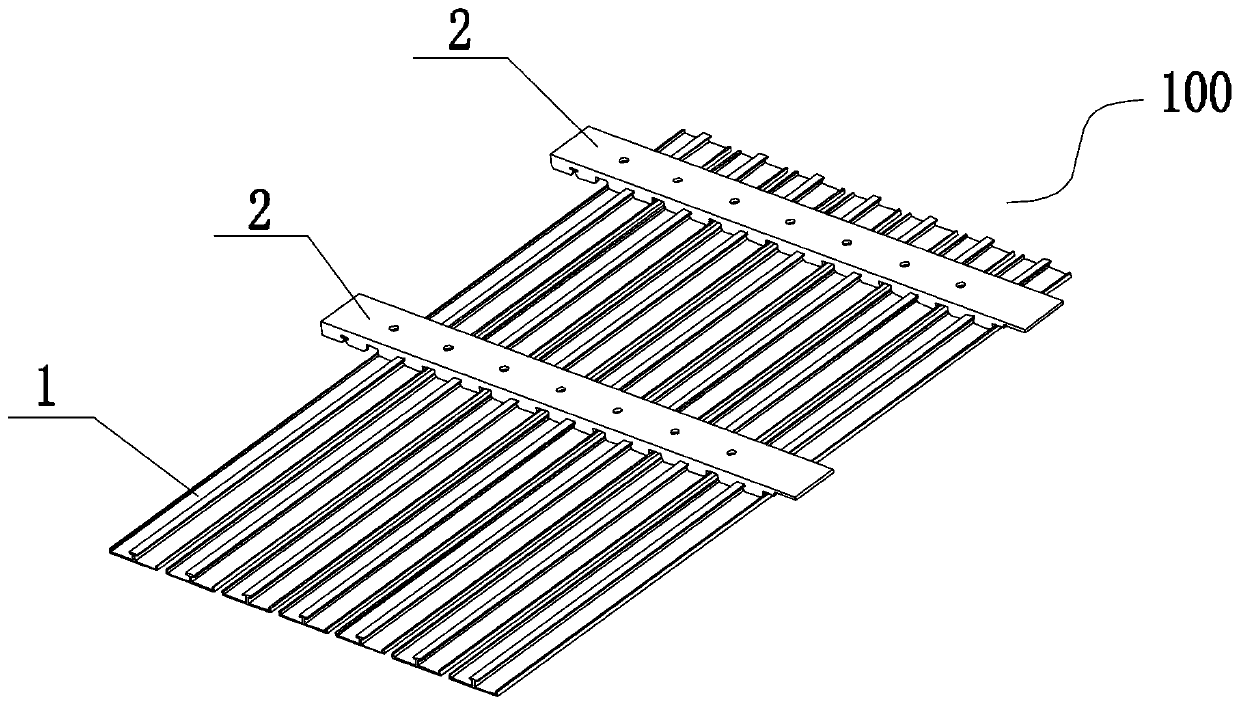

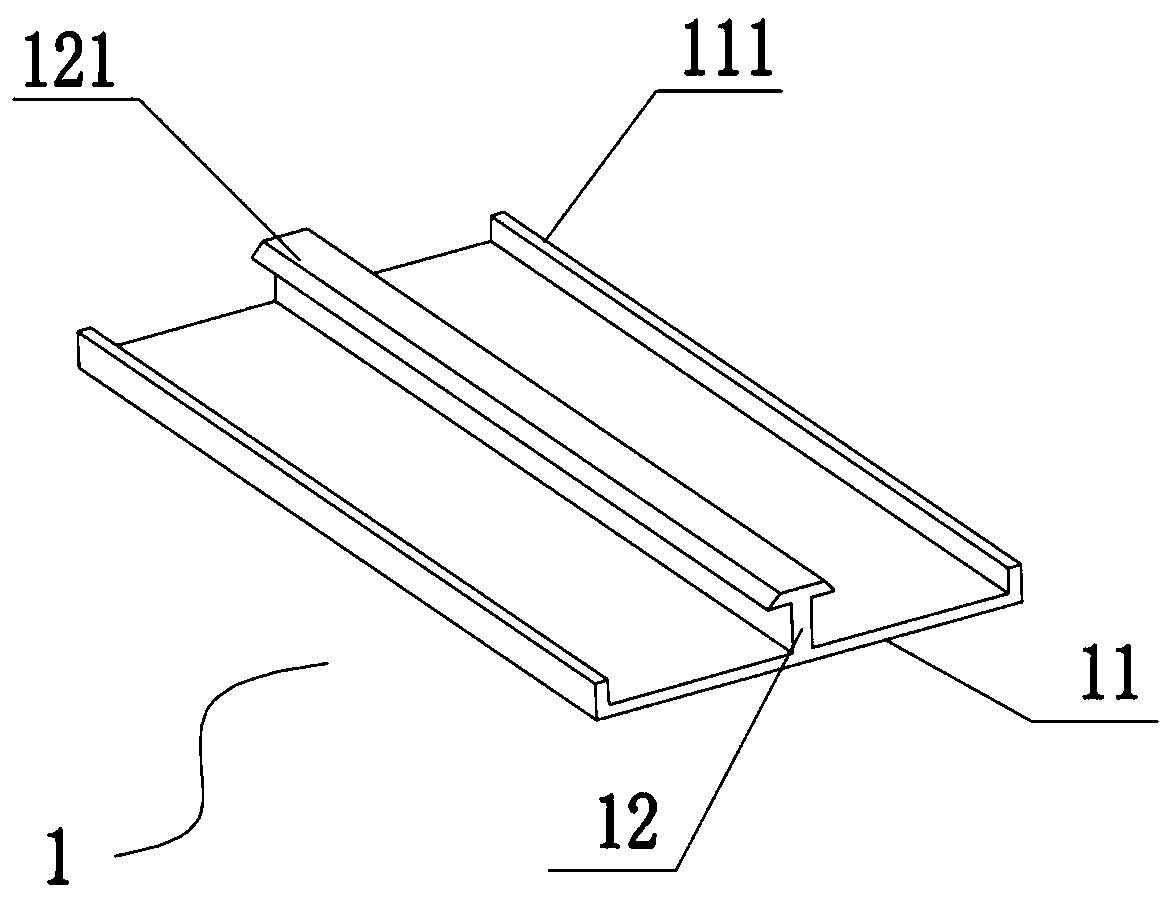

[0069] A single-leg slit sound-absorbing structure, comprising a plurality of slats 1 arranged in parallel and fixed on a keel 2 to form a panel 100 . A gap cavity 3 with a slit 31 outlet is formed between the slats 1 , the slat 1 includes a bar body 11 and a fixed leg 12 arranged on one side of the bar body 11 , each slat 1 Only a single fixing leg 12 is provided, which is used for fixed mounting of the slats 1 . The fixing leg 12 extends along the length direction of the slat 1 , and the end of the fixing leg 12 is provided with a fixing part 121 , and the fixing part 121 is made of ductile material. The lath 1 is aluminum alloy, and the keel 2 is alloy steel. The keel 2 has a simple structure and low cost, and is suitable as a fixed base for the slat 1 .

[0070] Sockets 21 are arranged on the keel 2 , and the fixed legs 12 are engaged with the sockets 21 . The cross section of the slat 1 is I-shaped, and the cross section of the fixing part 121 is trapezoidal in shape. ...

Embodiment 2

[0096] The difference between embodiment 2 and embodiment 1 is that the gap between the strip main bodies 11 of the adjacent slats 1 is 2mm. The area of the slit 31 accounts for 9.1% of the area of the entire panel 100

Embodiment 3

[0098] The difference between embodiment 3 and embodiment 2 is that the sound-absorbing layer 4 of glass wool with a thickness of 50 mm on the back is removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com