Building insulation board wall for building engineering field

A technology for construction engineering and heat insulation boards, which is applied in the directions of buildings, building components, building structures, etc., can solve the problems of poor heat insulation effect, inability to buffer ventilation due to external impact force, and inconvenience, so as to increase the heat preservation capacity and prolong the Heat flow path, the effect of avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

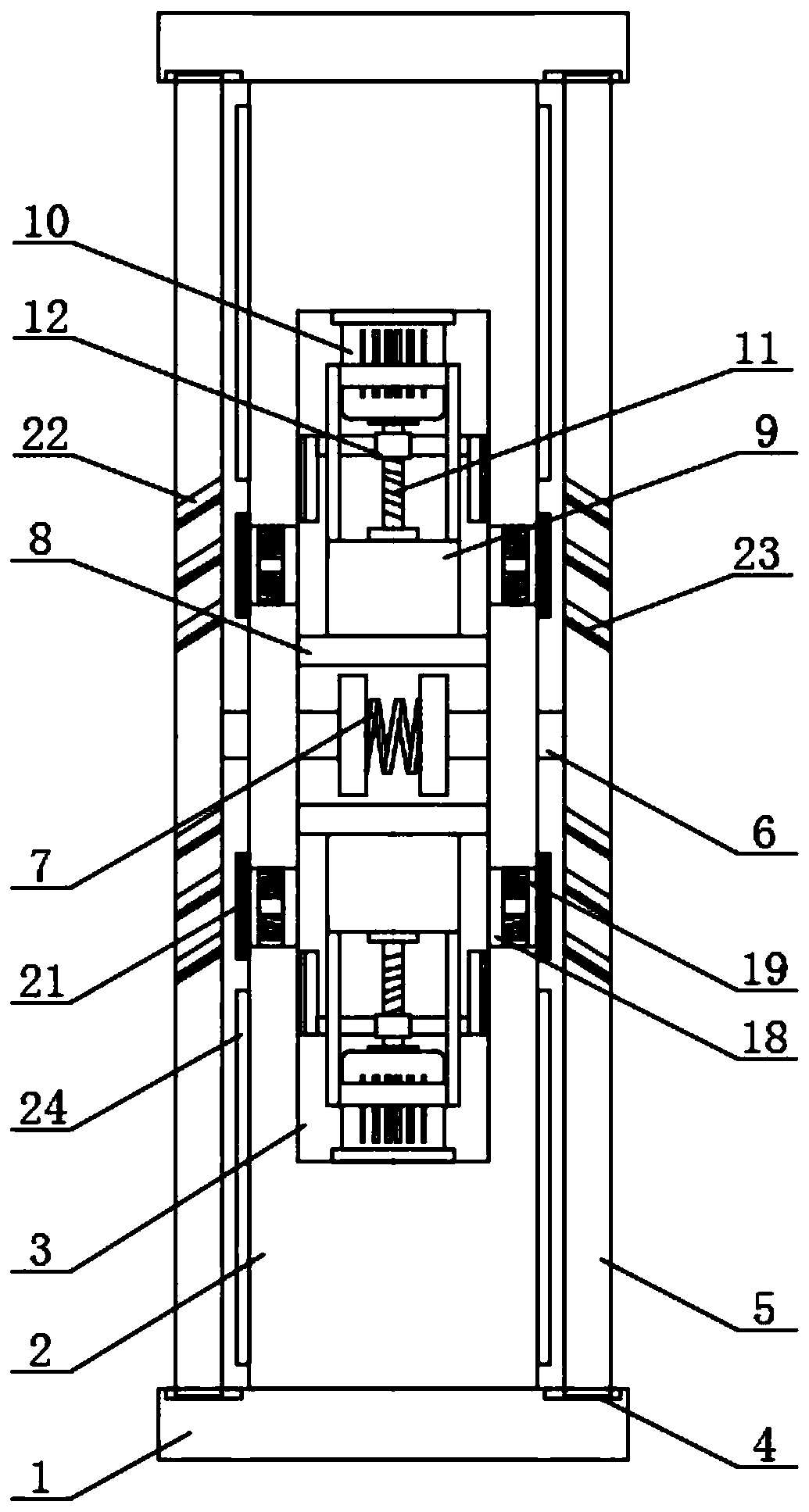

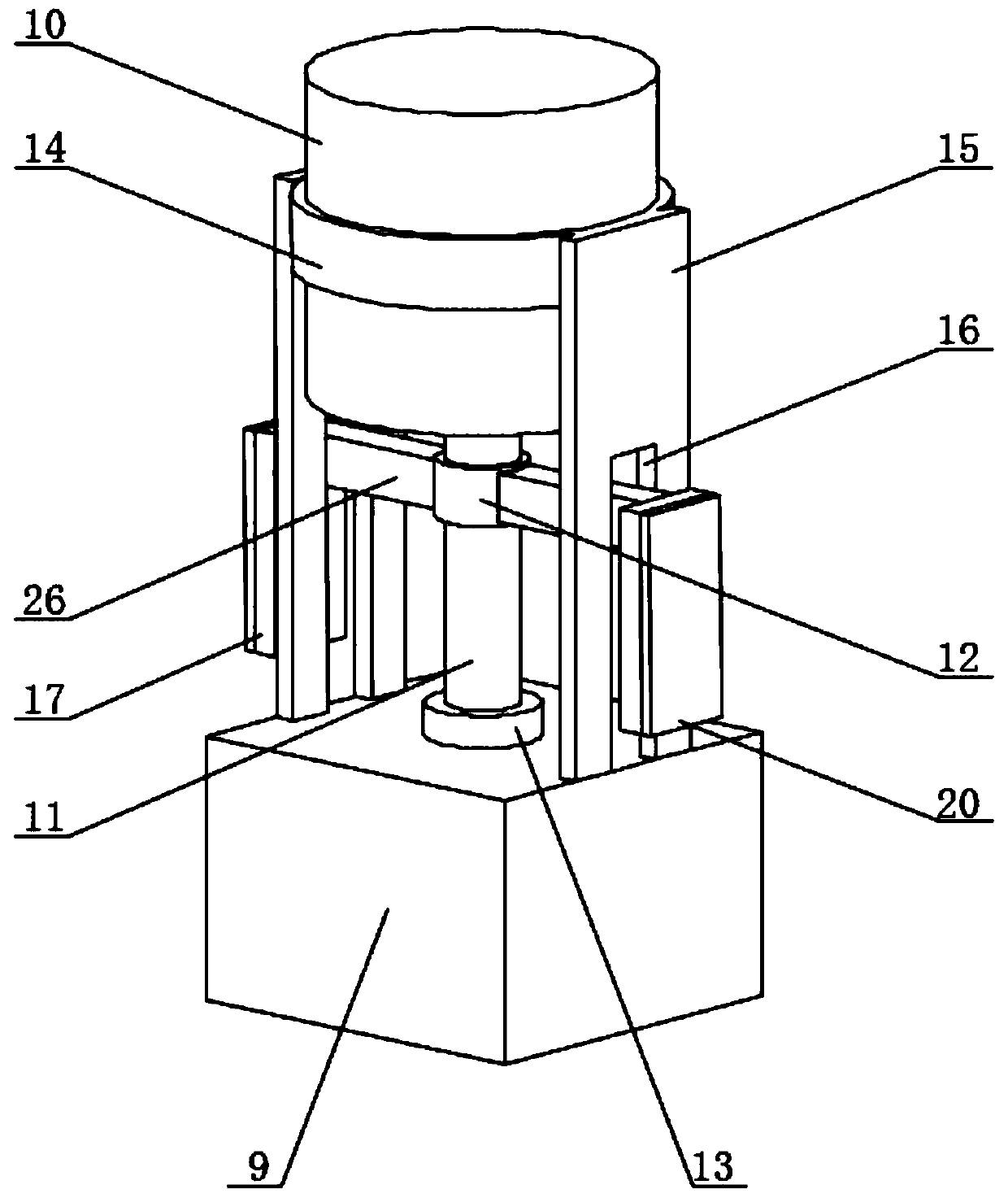

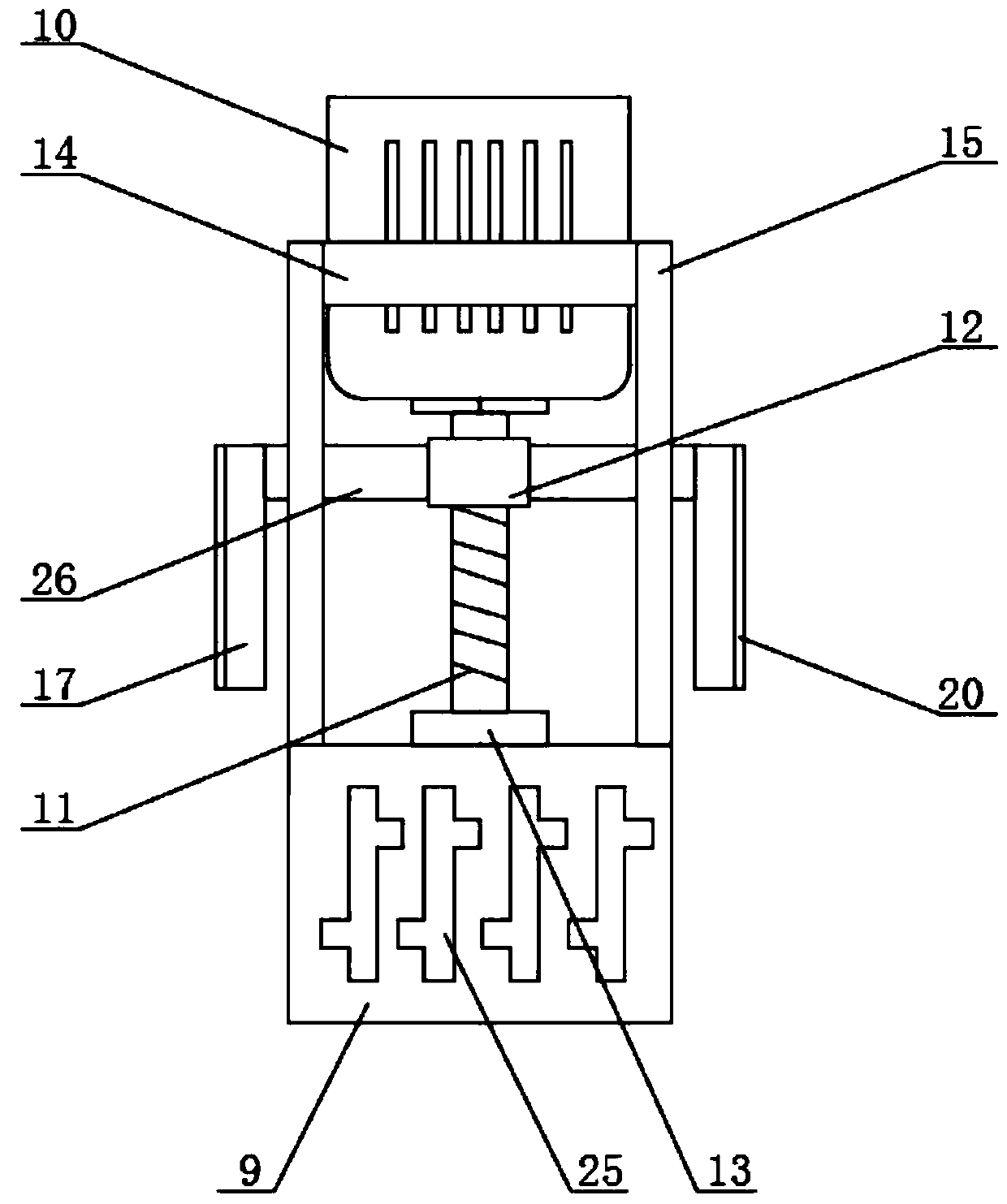

[0023] Such as Figure 1-4 As shown, the present invention provides a technical solution: a building insulation panel wall used in the field of construction engineering, including a fixing seat 1, the upper surface of the fixing seat 1 is fixedly connected with a wall 2, and the outer surface of the wall 2 is fixedly connected Filter screen 21 is arranged, and filter screen 21 is positioned at the same horizontal line as vent hole 18, can prevent external dust from entering the inside of body of wall 2 through vent hole 18 by setting filter screen 21, has improved the applicability of vent hole 18, the exterior of body of wall 2 The surface is fixedly connected with a foam cushion 24, and the thickness of the foam cushion 24 is not less than one centimeter. By arranging the foam cushion 24, the direct contact between the cushion plate 5 and the wall 2 can prevent wear and tear, and the overall heat preservation of the wall 2 can be increased. capacity, the inside of the wall 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap