Ultrathin clamping type carrier

A carrier and clamp-type technology, applied in the field of ultra-thin clamp-type carriers, can solve the problems of complex platform structure, easy to cause interference, many cables, etc., to achieve reasonable structure design, strong adaptability, reduced size and The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the objectives, technical solutions and advantages of the present invention clearer, a clear and complete description of the invention is given below in conjunction with the accompanying drawings and specific embodiments.

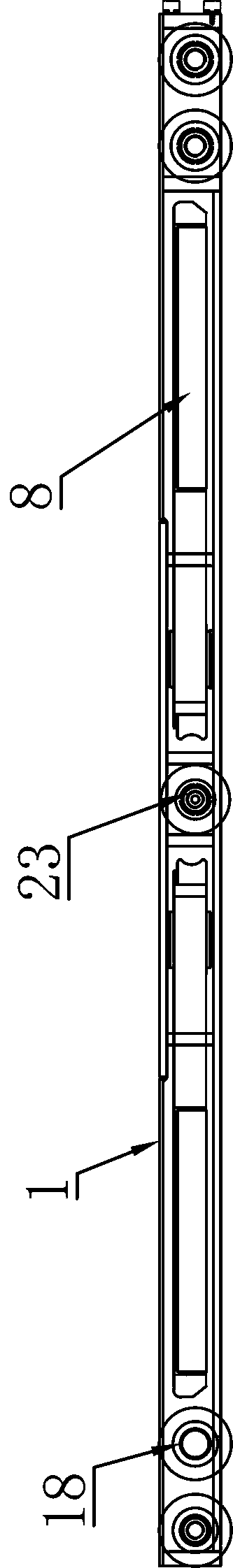

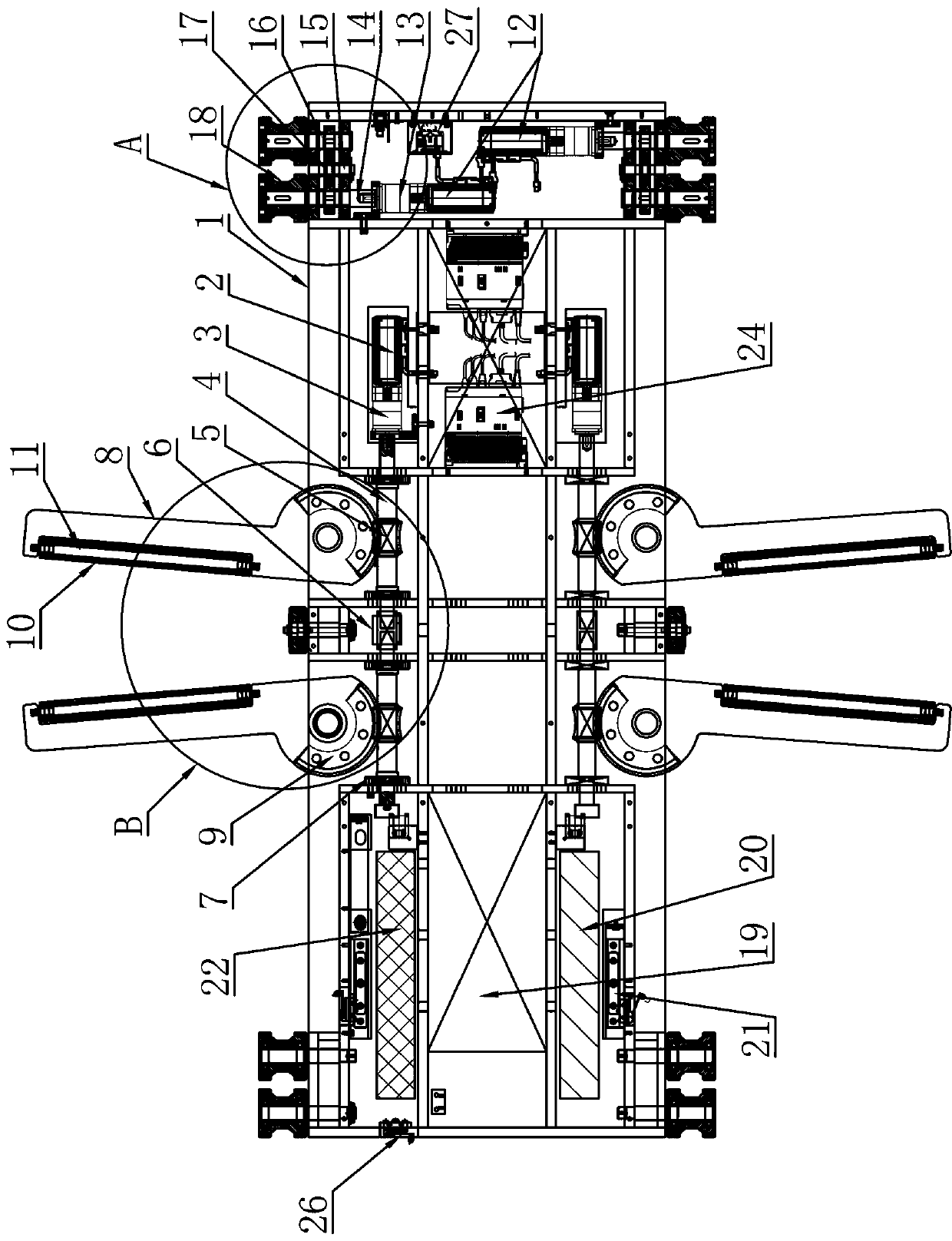

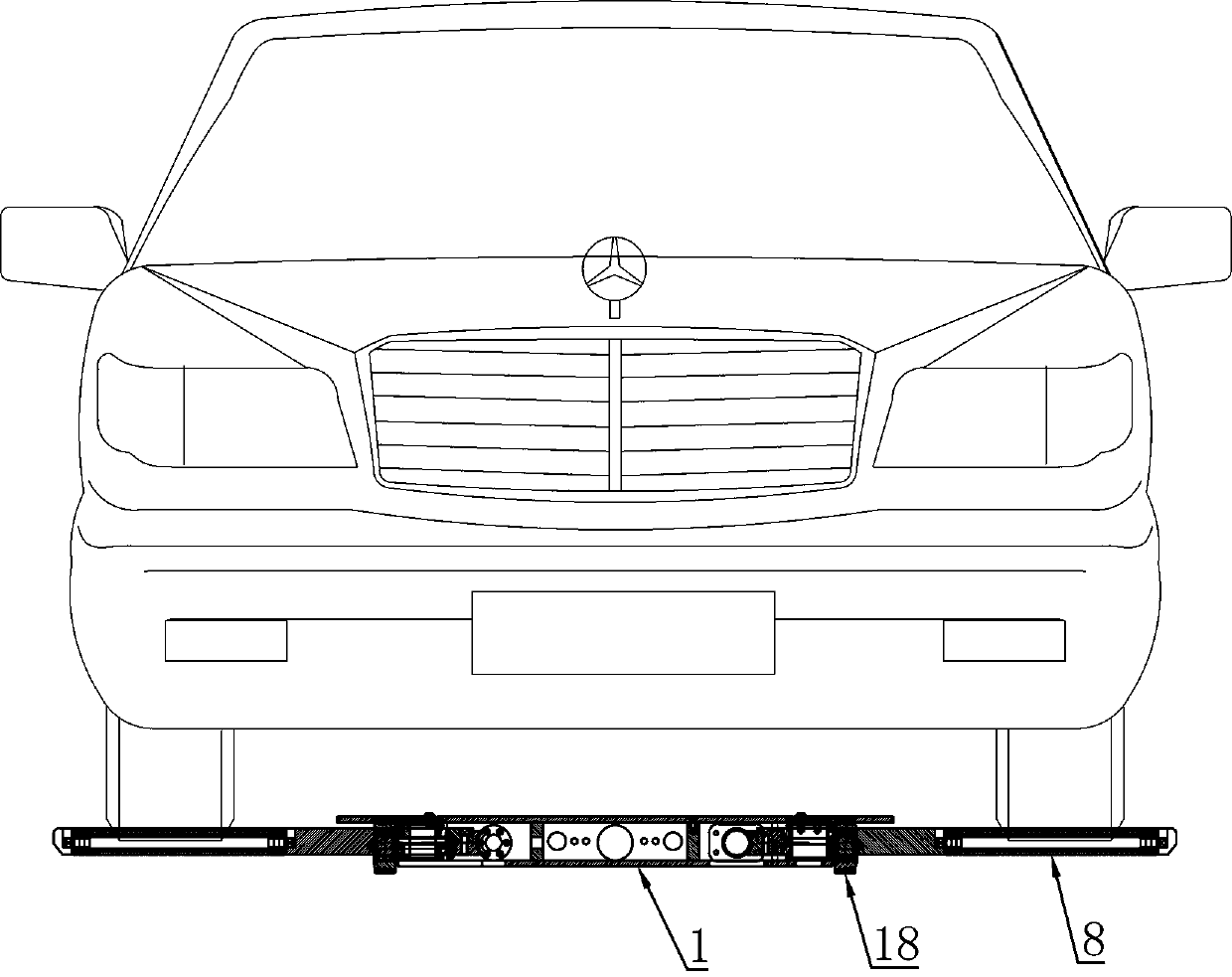

[0035] Such as Figure 1-6 An ultra-thin clamping carrier is shown, which includes a frame 1, a clamping mechanism and a walking mechanism arranged on the frame 1, and the clamping mechanism includes a symmetrical hinged connection to the frame 1. Two clamping arms 8 on the side, the clamping arm 8 can rotate horizontally with its root as an axis, the root of the clamping arm 8 is fixed with a worm gear 9, and the frame 1 is provided with two brackets 7 The worm 4 matched with the worm wheel 9 is provided with a bearing between the worm 4 and the bracket 7. The rotation directions of the worm teeth 5 on the two worms 4 are opposite, and the spiral teeth on the two worm wheels 9 are respectively Match with the worm teeth 5 of the two wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com