A processing and assembly process of radio frequency coaxial cable connector

A technology of radio frequency coaxial cable and assembly process, which is applied in the direction of connection, line/collector components, circuits, etc., can solve the problems of high production and assembly costs, complicated production and assembly process, and non-standard assembly process, so as to ensure consistency and stability, optimize the processing and assembly process, and reduce the effect of production and assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

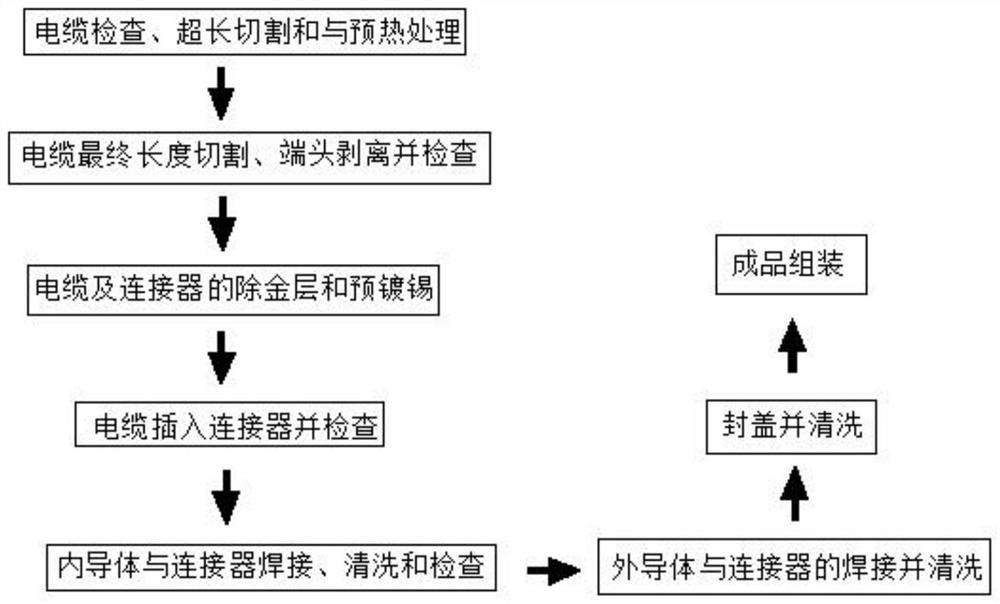

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: S1) Cable inspection, super-long cutting and preheating treatment: inspect the coaxiality, twist, ring, crack, sand hole and pollution of the inner and outer conductors of the assembled cables, and check the qualified ones according to the required length The cable is moderately long cut, and the cut cable is stored in a -45°C environment for 1 hour, then placed in a room temperature environment for 1 hour, and then the cable is placed in a thermal cycle device and heated to a maximum temperature of 65°C 1 hour, then put the cable at room temperature for 1 hour, and cut the axis of the cable and the edge of the outer conductor flat, repeat the complete thermal cycle 3 times, the temperature change rate of the cable preheating treatment is not higher than 2 ℃ / minute, and heat it at the end After the cycle is completed, put it in room temperature for 1 day, and put it into the thermal cycle device when the cable is preheated;

[0025] S2) The final length ...

Embodiment 2

[0033] Embodiment 2: S1) Cable inspection, super-long cutting and preheating treatment: inspect the coaxiality, twist, ring, crack, sand hole and pollution of the inner and outer conductors of the assembled cables, and check the qualified ones according to the required length The cable is moderately long cut, and the cut cable is stored in a -40°C environment for 1.5 hours, then placed in a room temperature environment for 1.5 hours, and then the cable is placed in a thermal cycle device and heated to a maximum temperature of 70°C 1.5 hours, then put the cable at room temperature for 1.5 hours, and cut the axis of the cable and the edge of the outer conductor flat, repeat 4 complete thermal cycles, the temperature change rate of the cable preheating treatment is not higher than 2°C / min, and heat at the end After the cycle is completed, put it in room temperature for 1.5 days, and put it into the thermal cycle device when the cable is preheated;

[0034] S2) The final length of...

Embodiment 3

[0042] Example 3: S1) Cable inspection, super-long cutting and preheating treatment: inspect the inner and outer conductors for coaxiality, distortion, rings, cracks, blisters and pollution on the assembled cables, and check the qualified ones according to the required length The cable is moderately long cut, and the cut cable is stored in a -40°C environment for 2 hours, then placed in a room temperature environment for 2 hours, and then the cable is placed in a thermal cycle device and heated to a maximum temperature of 75°C 2 hours, then put the cable at room temperature for 2 hours, and cut the axis of the cable and the edge of the outer conductor flat, repeat 4 complete thermal cycles, the temperature change rate of the cable preheating treatment is not higher than 2 ℃ / minute, and at the end of the heating After the cycle is completed, put it in room temperature for 1.5 days, and put it into the thermal cycle device when the cable is preheated;

[0043] S2) The final le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com