A propeller folding mechanism for a catapult UAV

A folding mechanism and UAV technology, applied in the field of UAVs, can solve the problems of time-consuming and labor-intensive propellers, and the inability to realize hot start, etc., and achieve the effect of less preparation work, less space for launch, and intensive launch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make those skilled in the art better understand the technical solutions of the present invention, the following describes the propeller folding mechanism for ejector UAV in further detail with reference to the accompanying drawings and specific embodiments.

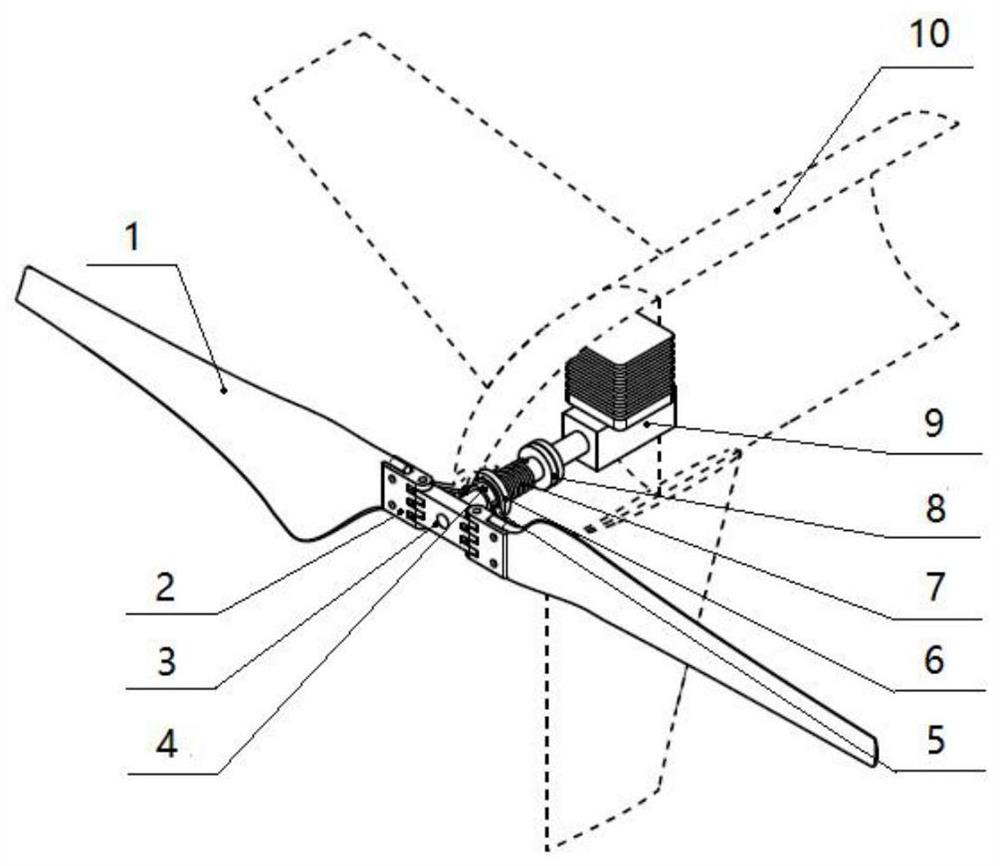

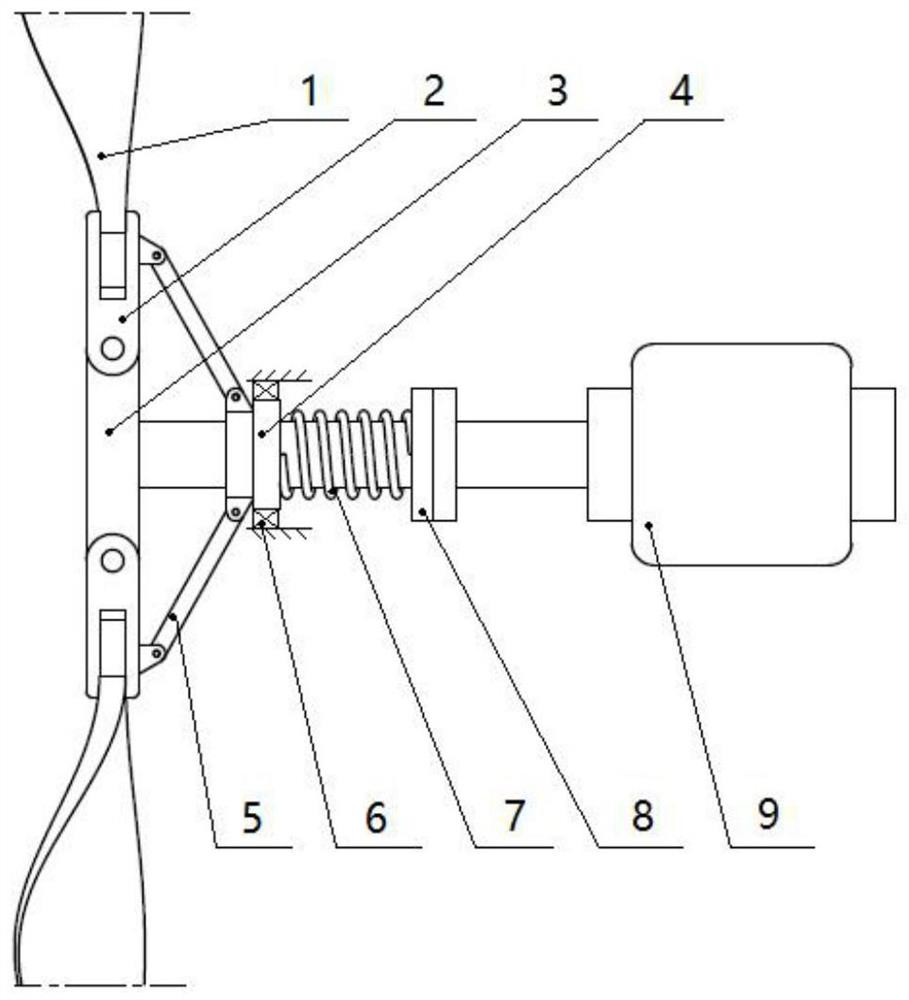

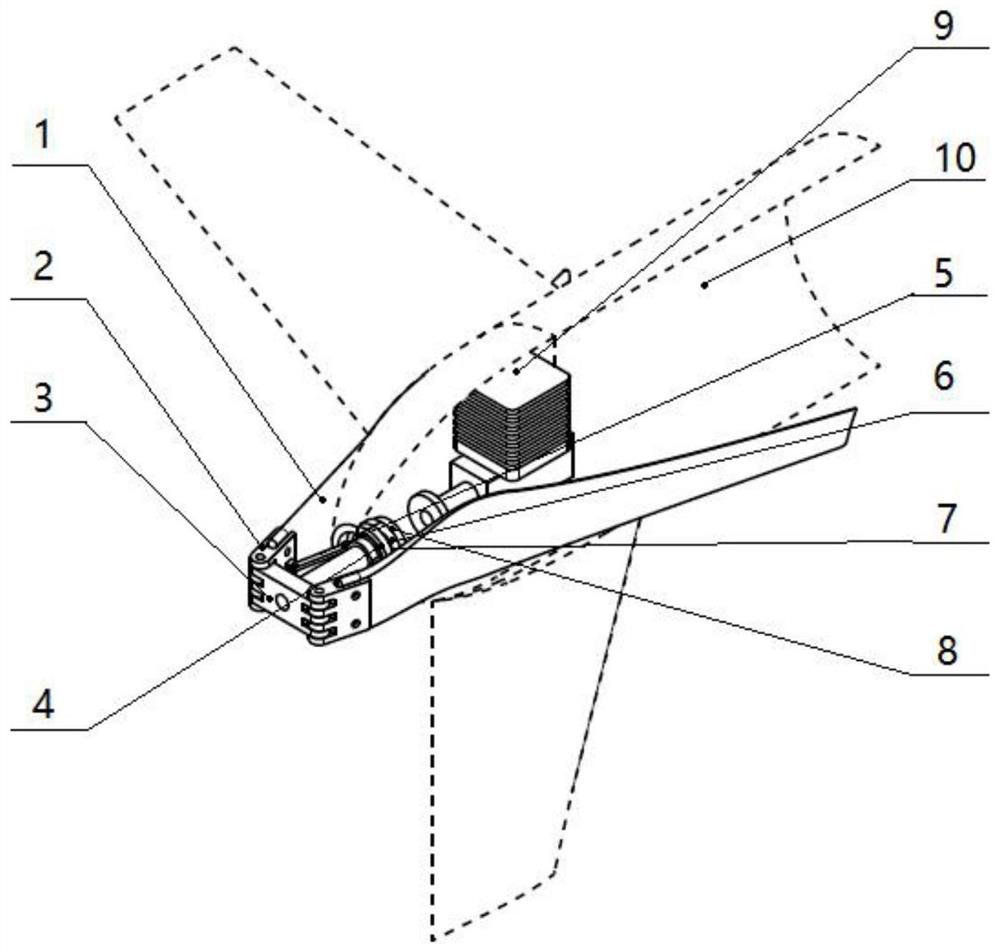

[0018] like Figure 1-Figure 4 shown,

[0019] A propeller folding mechanism for ejection-type unmanned aerial vehicles, comprising a propeller blade 1 hinged on a propeller hub 3 through a blade hinge 2, the rotating shaft of the paddle hub 3 is inserted into the shaft sleeve 4, and the connecting rod 5 is hinged on the ear of the shaft sleeve 4. On the plate, the other end of the connecting rod 5 is connected with the ear piece of the blade hinge 2, the shaft sleeve 4 is installed at the rear of the fuselage 10 through the thrust bearing 6, and the half friction plate of the clutch 8 is fixed on the rotating shaft of the blade 3 through bolts, The pressure-bearing spring 7 is sleeved on the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com