Combined three-phase common-body electronic current and voltage transformer

A voltage transformer, electronic current technology, applied in the direction of inductors, transformers/inductor shells, transformers, etc., can solve the shielding effect, poor anti-interference ability, difficult to meet high-performance testing, difficult to obtain uniform internal electric field distribution, etc. problem, to achieve the effect of good self-cleaning performance, great practical and popularization value, and uniform distribution of the internal electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

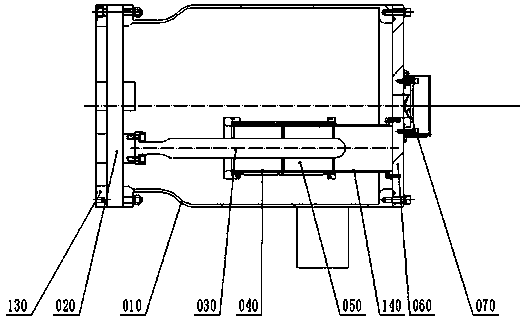

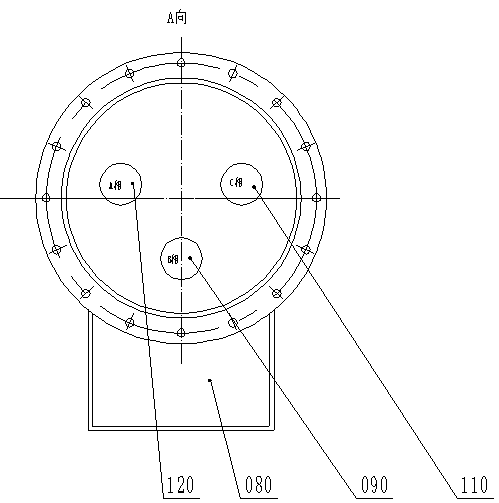

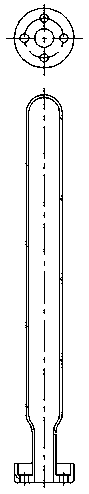

[0017] The upper positioning flange (130) is fixed on the upper half of the housing (010); the basin insulator (020) is connected with the housing (010); the primary conductive rod (030) is connected to the basin insulator ( 020) conductors are connected; the current coil shielding tube (040) is fixed on the lower positioning flange (060); the current coil (050) is arranged around the current coil shielding tube (040); three sets of primary conductive rods ( 090, 110, 120), the current coil shielding cylinder (040), and the current coil (050) are evenly distributed in the casing (010) to form a three-phase electronic current transformer; a shielding is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com