Special conveyor for degradable occluder

A technology of occluder and conveyor, which is applied in the field of medical equipment, can solve the problems of occluder implantation, etc., and achieve the effect of round front end, convenient operation, and simple and convenient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

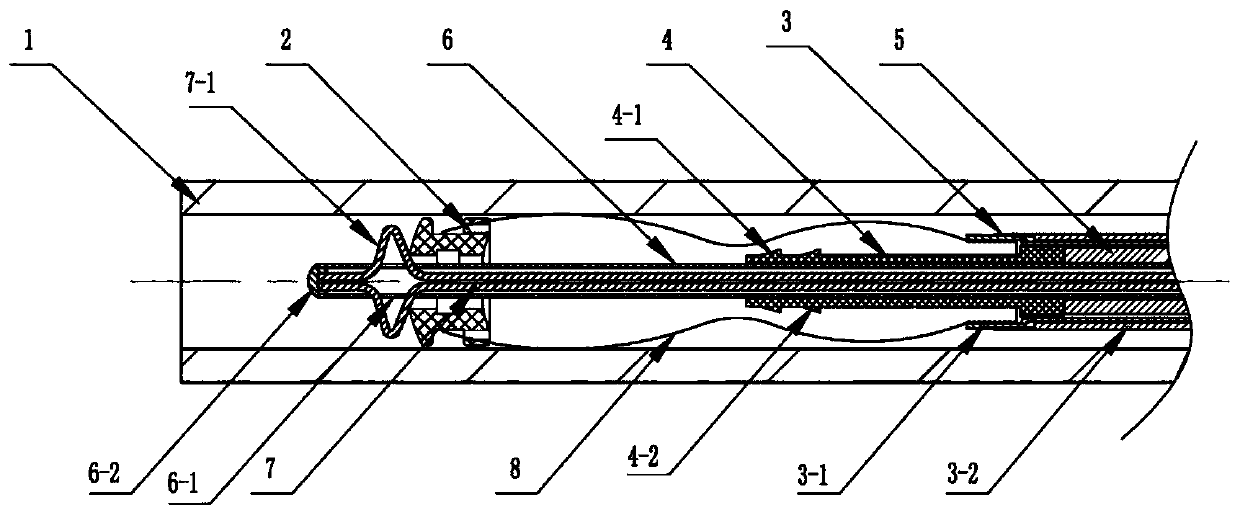

[0053] Such as Figure 1 to Figure 5 A special conveyor for a degradable occluder is shown, including: a sheath tube 1, a cap 2, a clamping device 3, a lock 4, a positioning rod 5, a pull rod outer tube 6, a pull rod 7, and a degradable occluder 8.

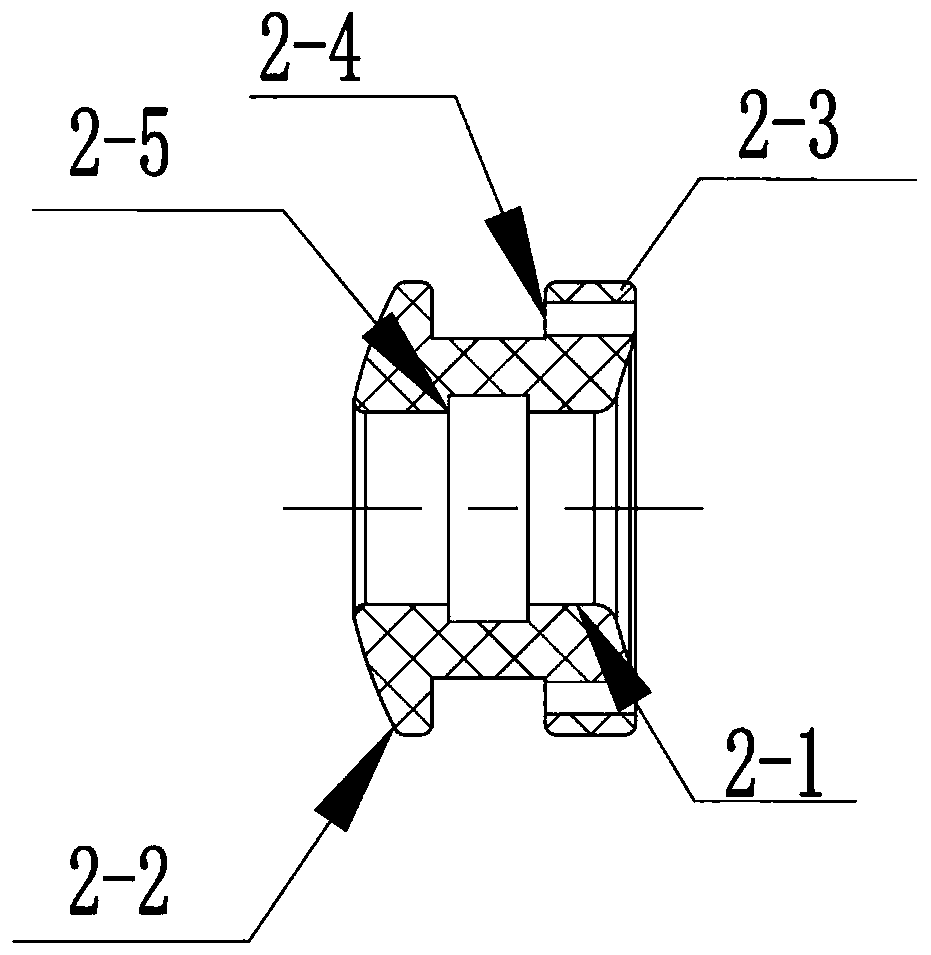

[0054] Such as figure 1 As shown, the cap 2 , the clamping device 3 , and the degradable occluder 8 are all arranged in the sheath tube 1 . The head of the degradable occluder 8 is fixedly connected to the cap 2, and the tail is connected to the clamping device 3; the front and middle parts of the lock 4 are inserted into the degradable occluder 8 from the tail of the degradable occluder 8, The rear part is set in the tightening device 3; the front part of the positioning rod 5 is set in the tightening device 3, and its front end surface is in contact with the rear end surface of the lock buckle 4; 4. The degradable occluder 8 and the cap 2; the tie rod 7 is arranged in the outer tube 6 of the tie rod.

[0055] Such as figur...

Embodiment 2

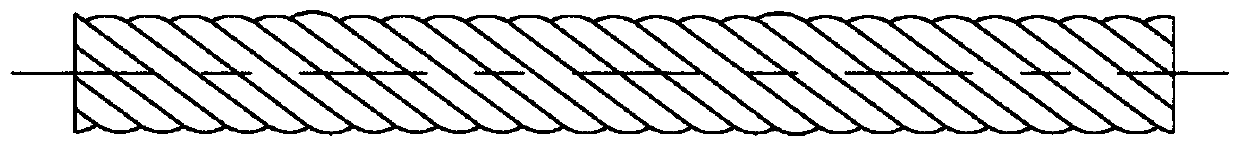

[0066] The structure of embodiment 2 is similar to that of embodiment 1, except that the structure of the outer tube 6 of the tie rod is different. Such as Figure 10 The outer tube 6 of the pull rod shown in Embodiment 2 is a braided outer tube, which includes a PTFE tube layer, a metal braided wire tube layer, and a PA / PU tube layer from the inside to the outside. The braided outer tube has strong tensile strength and a PTFE tube inside. Layer, smooth inner wall, good lubricity, easy to penetrate, accurate positioning.

Embodiment 3

[0068] Embodiment 3 is similar in structure to Embodiment 1, except that the structure of the fastening tube 3-1 is different. Such as Figure 11 and Figure 12 The fastening tube 3-1 of the shown embodiment 3 has four notches at the front end, so that the front end of the fastening tube 3-1 is more elastic than that of the first embodiment, and the head is designed in a tooth shape, which is convenient and degradable for plugging Device 8 is tightly combined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com