Manufacture process of soft capsule shells

A manufacturing process and soft capsule technology, applied in the field of soft capsule rubber manufacturing process, can solve problems such as uneven dispersion and sticky glue, and achieve the effect of uniform sol, simple process flow, and convenient addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

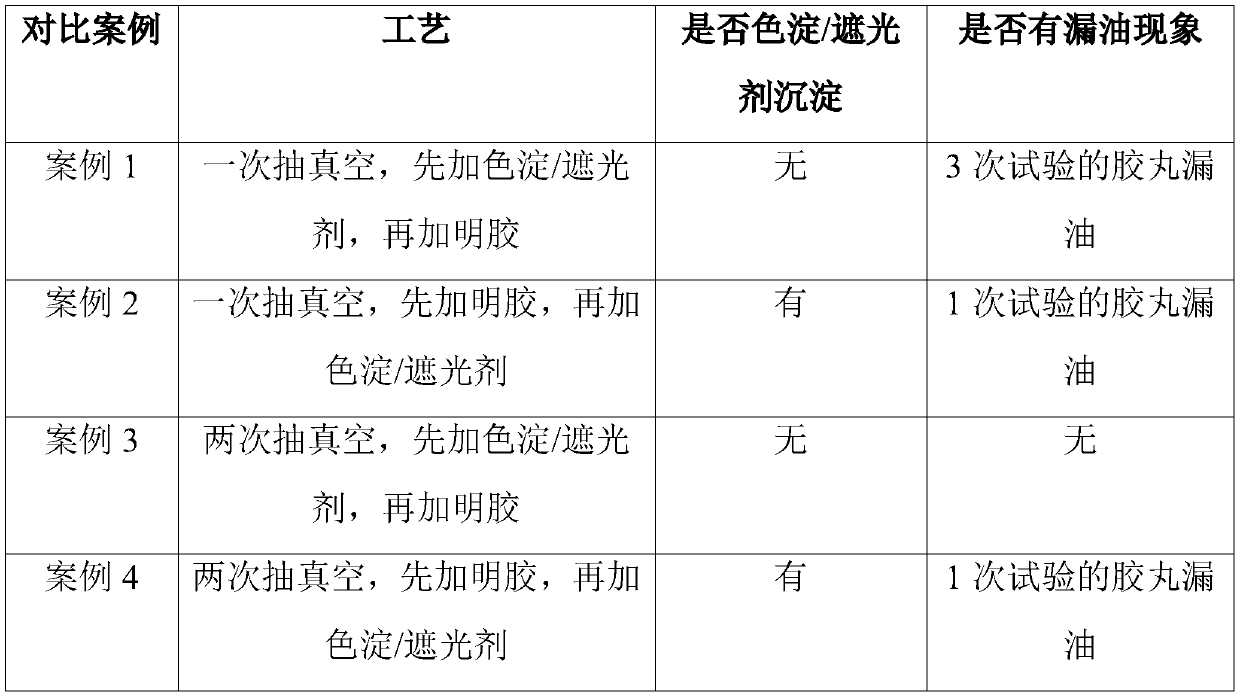

Examples

Embodiment

[0030] This embodiment provides a soft capsule rubber, which includes 9-11 parts of purified water, 0.1-0.5 parts of color lake / sunscreen agent, 9-11 parts of gelatin and 3-6 parts of glycerin. The following describes the soft capsule rubber manufacturing process in detail:

[0031] First step, high shear stage: extraction of purified water, and the lake / opacifier was dispersed in the purified water under high shear for 20 min.

[0032] The second step, the warm-up phase: the Add purified water and glycerin into the glue tank, and at 70°C to 90°C, add the dispersed color lake / opacifier in the high-shear stage into the glue tank; extract and use the remaining Rinse the inner wall of the chemical glue tank with purified water, stir evenly and let it stand for use;

[0033] The third step, the sol stage: add gelatin into the glue tank that has been preheated, and stir the sol for 3-5 minutes;

[0034] The fourth step, the first vacuuming stage: at a vacuum degree of -0.08M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com