Magnetic adsorption self-arrangement circulation deburring machine and deburring method

A deburring machine and deburring technology, which is applied to the parts of grinding machine tools, automatic grinding control devices, and machine tools suitable for grinding the edge of workpieces, etc. problem, to save the time of manual inspection and rework, good deburring quality, and easy batch processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

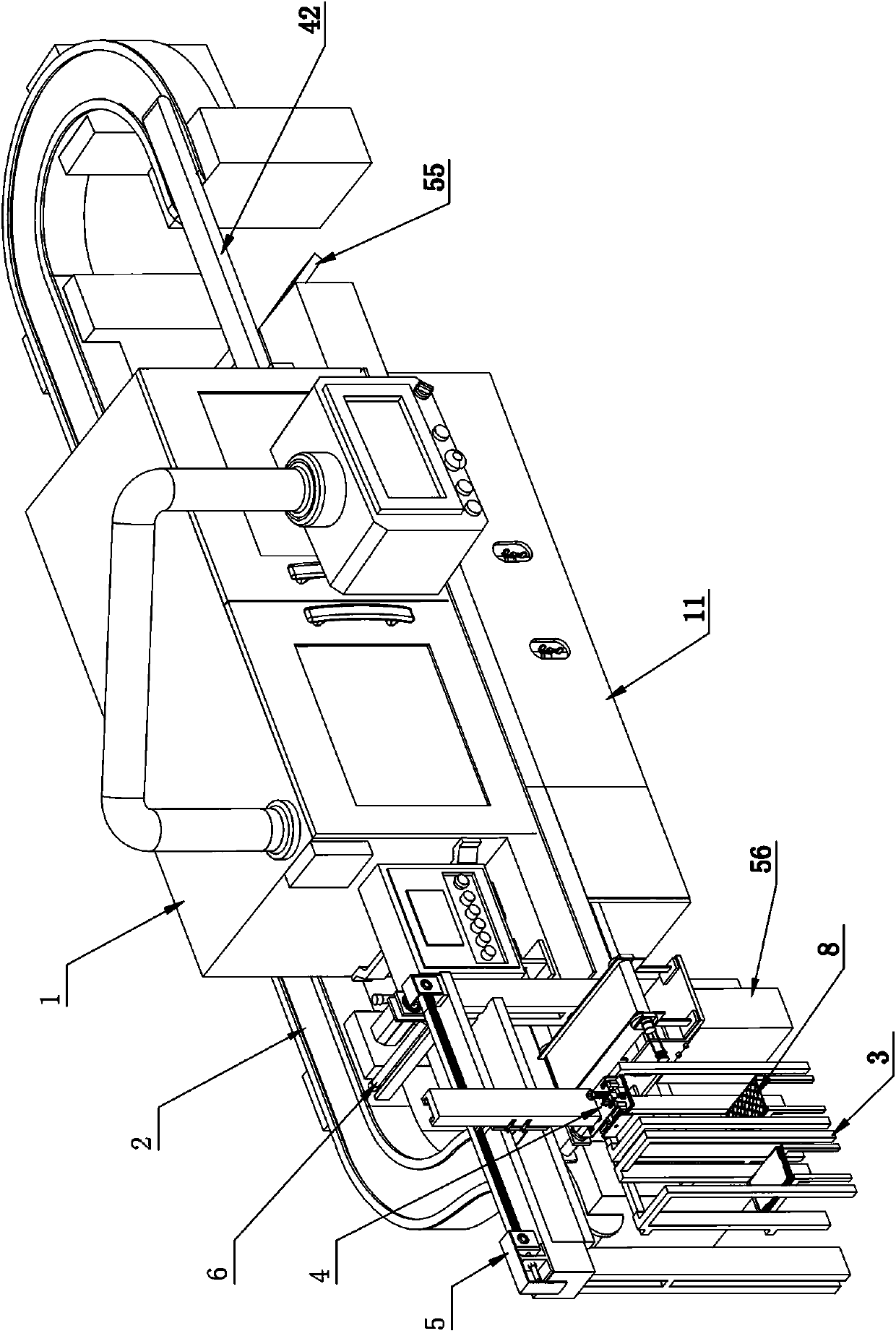

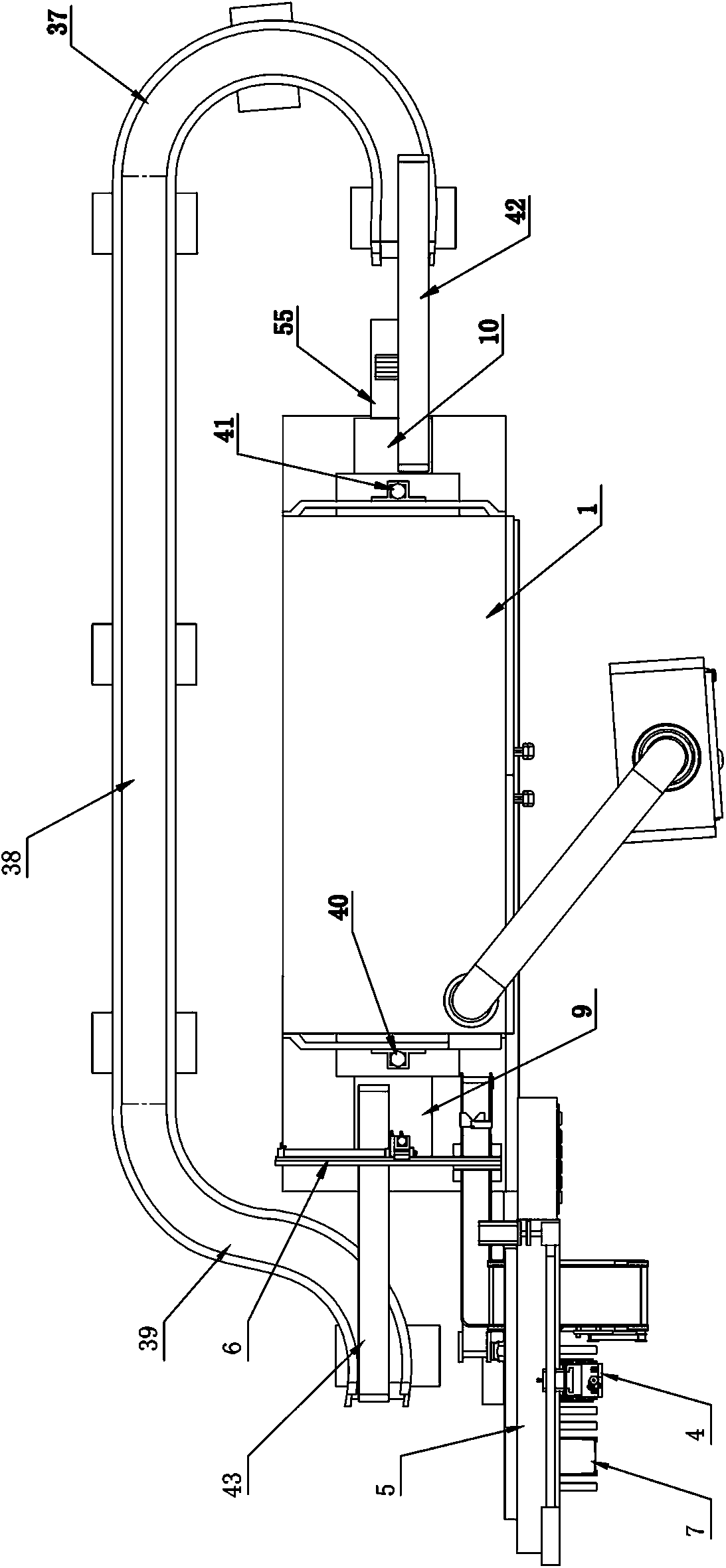

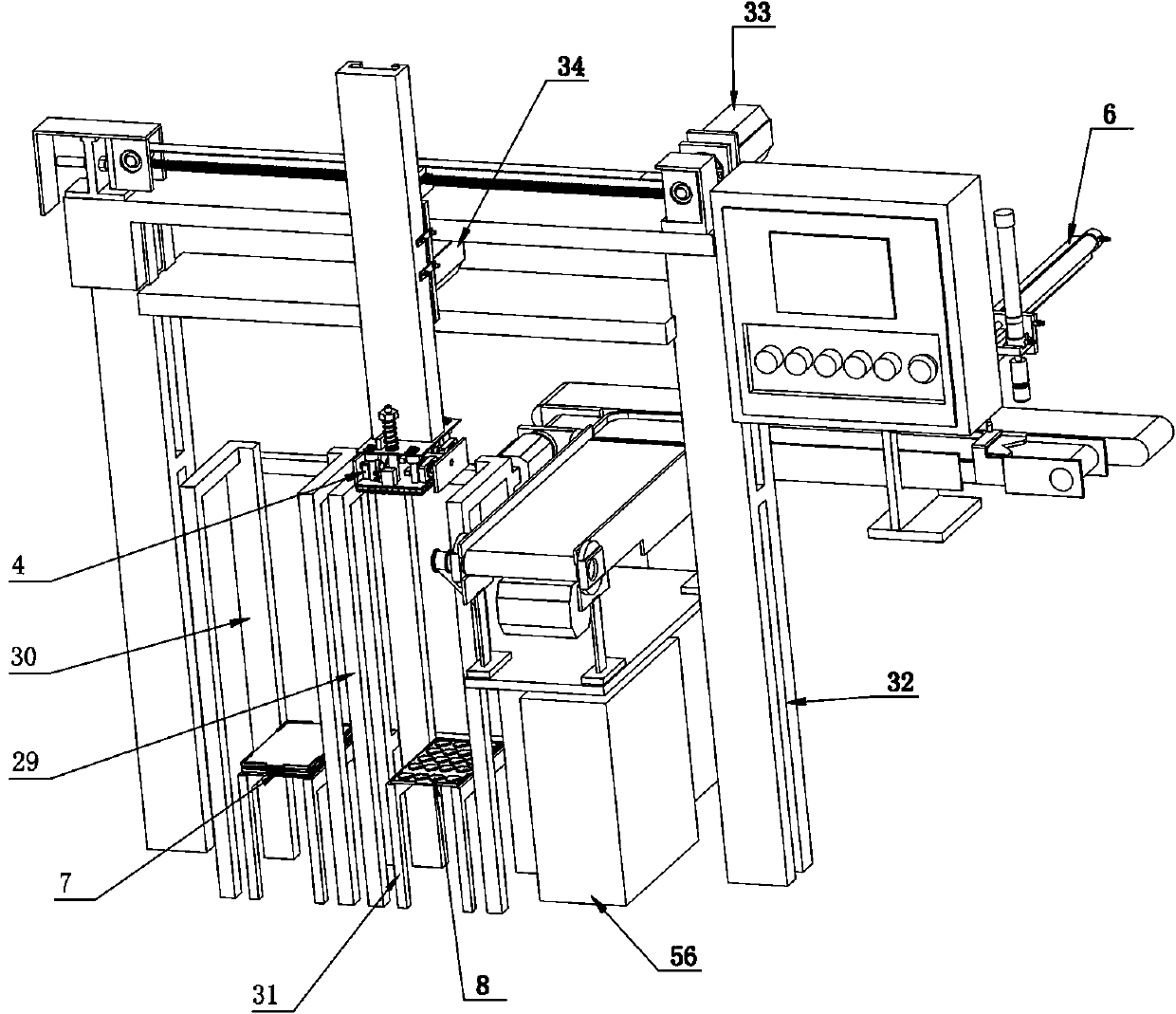

[0029] refer to Figure 1~Figure 8 , the present invention provides a magnetic self-arrangement cycle deburring machine and a deburring method, the magnetic self-arrangement cycle deburring machine includes a deburring device 1 and a workbench 11, and also includes a deburring device installed on the workbench 11 and connected to the deburring device respectively. The rotary conveyor belt 2 connected to the device 1 and the automatic arrangement feeding device 3; the automatic arrangement feeding device 3 includes a magnetic suction mechanism 4, a feeding mechanism 5 and a sorting mechanism 6, and the magnetic suction mechanism 4 is installed on the feeding mechanism 5; the magnetic suction mechanism 4 is used The workpieces 8 arranged in matrix on the adsorption tray 7 are transferred to the sorting mechanism 6 by the feeding mechanism 5; the feeding port of the deburring device 1 is provided with a feeding conveyor belt 9 corresponding to the sorting mechanism 6, and the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com