A processing device and process for fluid deburring of copper-tungsten alloy contacts

A copper-tungsten alloy and processing device technology, which is applied in metal processing equipment, used abrasive processing devices, explosion generating devices, etc., can solve the problems of poor deburring quality and low deburring efficiency, and achieve high processing efficiency, The effect of good deburring quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

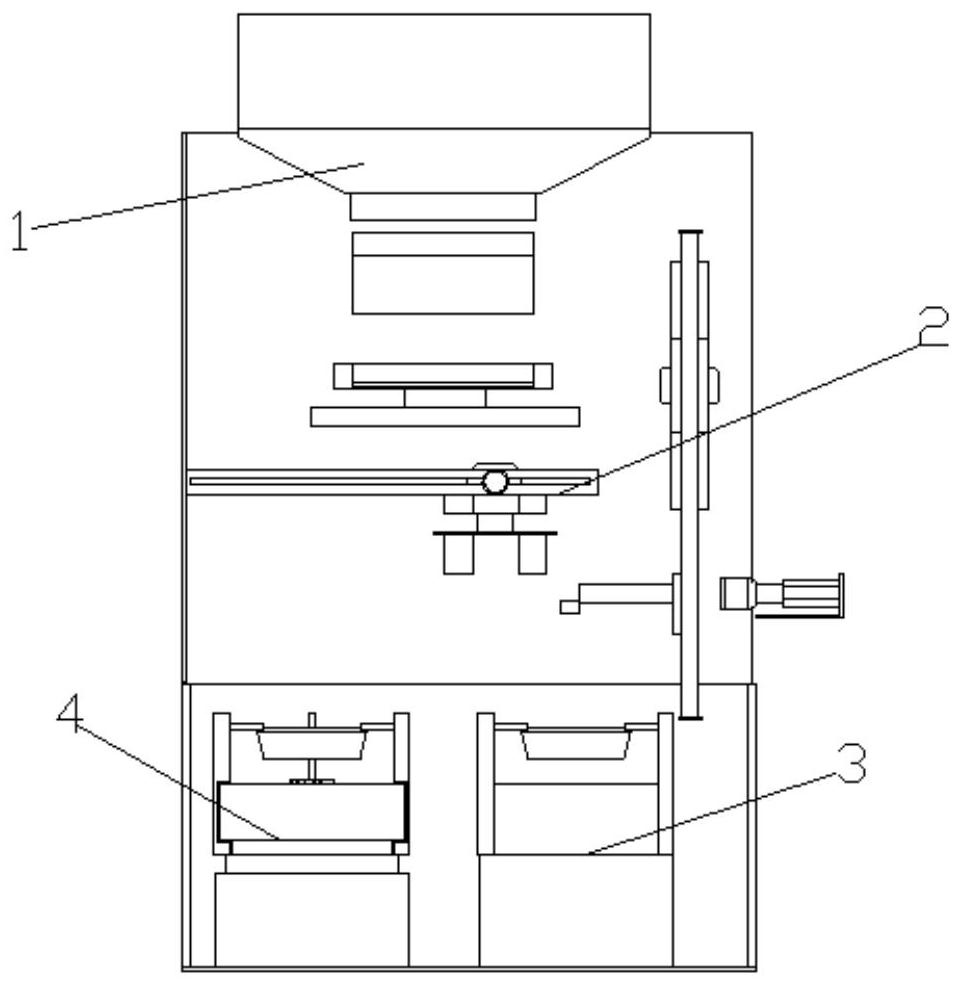

[0042] like figure 1 A processing device for fluid deburring of copper-tungsten alloy contacts shown: including a support box placed on the ground, a feeding device 1 arranged on the upper end of the support box for placing copper-tungsten alloy contacts, and arranged on the support. The lower end of the box body is used for deburring the copper-tungsten alloy contacts.

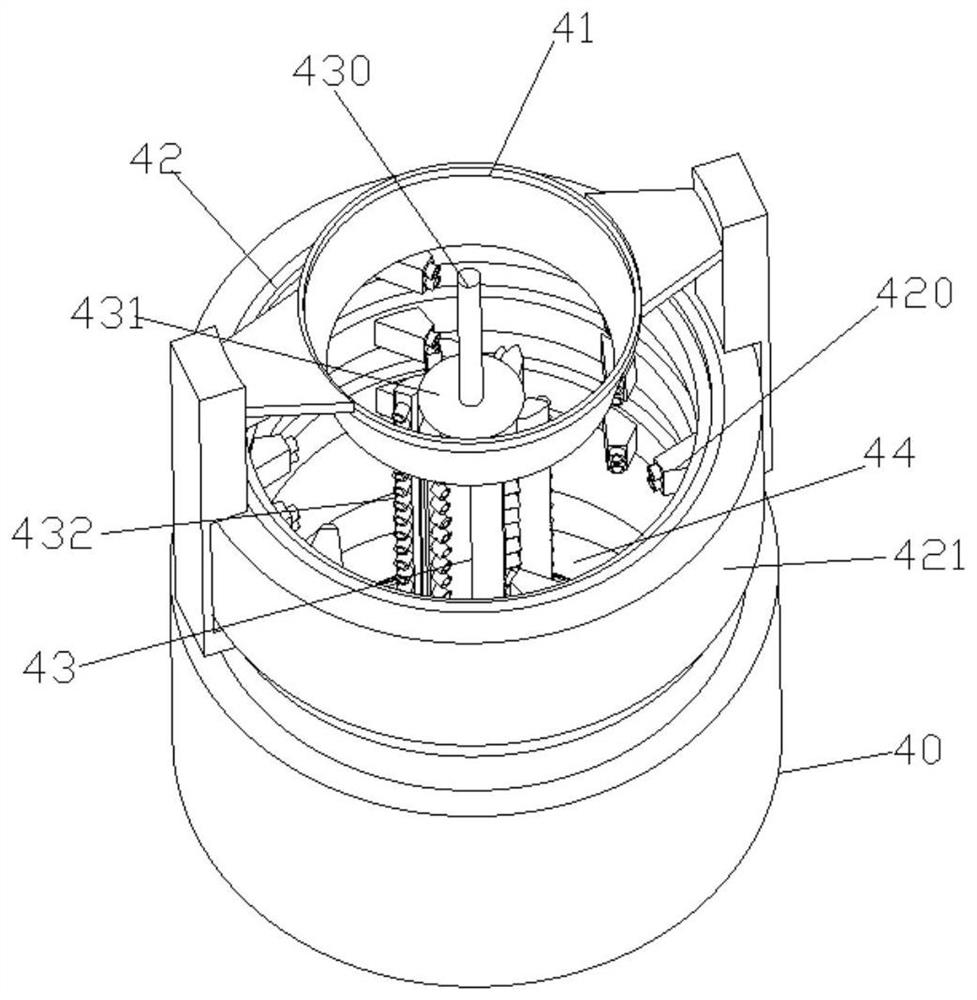

[0043] The composite deburring device includes a first deburring device 3 arranged at the lower end of the supporting box to deburr the copper-tungsten contacts, and a second deburring device 3 arranged at the lower end of the supporting box to perform a second deburring treatment on the copper-tungsten contacts. Deburring device 4;

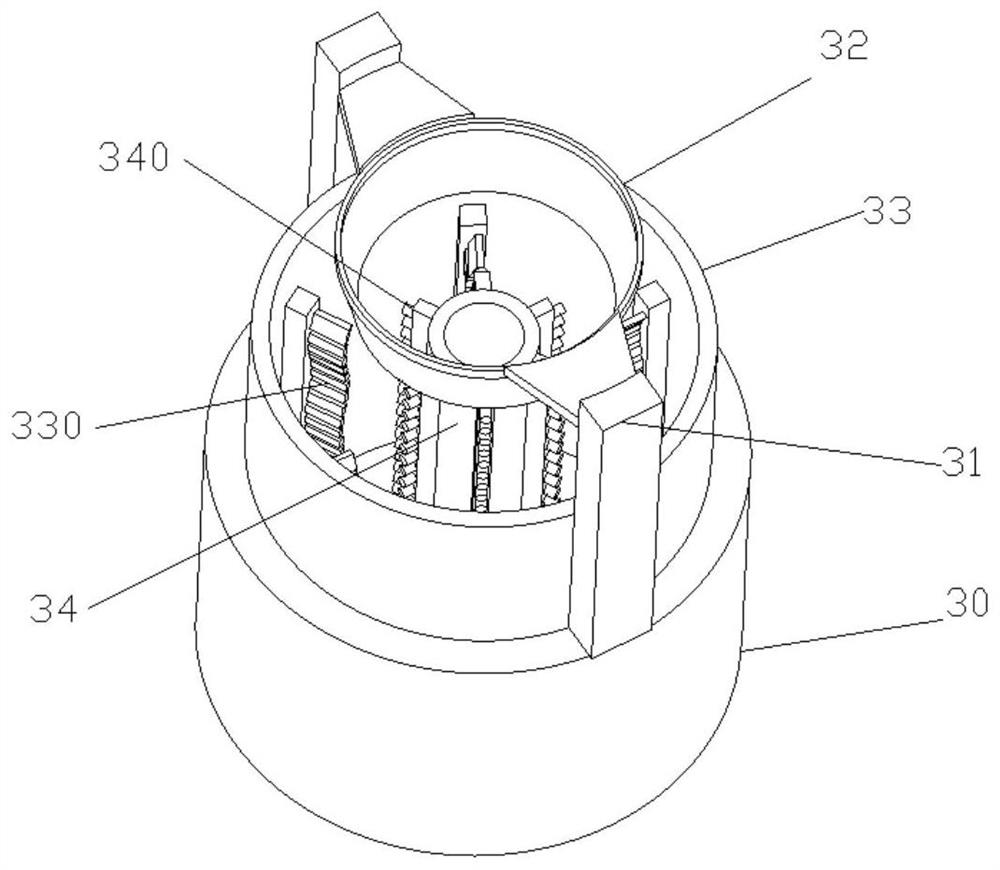

[0044] The first deburring device 3 includes three sets of scraping devices arranged side by side;

[0045] like figure 2 As shown, the scraping device includes a first outer fixing cylinder 30 , a bracket ring 31 arranged on the first outer fixing cylinder 30 , a copper tun...

Embodiment 2

[0056] The difference from Example 1 is: as Figure 4 As shown, the feeding device 1 includes a contact placement box 10 arranged at the upper end of the support box for placing copper-tungsten contacts, a feed opening 11 arranged at the lower end of the contact placement box 10, and a steering wheel arranged below the feed opening 11 The table 13, and the feeding chute 12 whose upper end is located just below the feeding port 11 and whose lower end can be connected to the turning table 13;

[0057] The feeding chute 12 is inclined at an angle of 30° to the ground;

[0058] The feeding port 11 is a rectangular opening, the length of which is 3mm greater than the length of a single copper-tungsten contact, and the width is 5mm greater than the outer wall diameter of the copper-tungsten contact;

[0059] The turning table 13 includes a mounting plate 130 fixed on the support box, a rotating frame 131 movably arranged on the mounting plate 130, a turning and placing slot 132 sli...

Embodiment 3

[0067] Utilize the device of above-mentioned embodiment 1 to carry out the processing technology of fluid deburring to copper-tungsten alloy contact, comprising the following steps:

[0068] Step 1: First Deburring

[0069] First, the copper-tungsten contacts are scraped and ground for the first time to remove burrs;

[0070] Specifically: after connecting the copper-tungsten contact with the copper-tungsten contact clamping sleeve 32 Rotate upward, use the first flexible brush 330 and the second flexible brush 340 to scrape, grind and deburr the inner and outer walls of the contacts in the fluid abrasive medium for 20 minutes;

[0071] Step 2: Second Deburring

[0072] Then perform a second fluid deburring on the copper-tungsten contacts;

[0073] Specifically: after the copper-tungsten contact is connected to the fixed sleeve 41, the outer wall jet nozzle 420 and the inner wall jet 432 spray fluid abrasives to the inner and outer walls of the copper-tungsten contact respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com