Log debarking device for wood processing

A log and lumber technology, applied in the field of log debarking devices for wood processing, can solve the problems of high processing cost, affect operation, consume a lot of manpower and material resources, and achieve the effects of reducing workload, improving safety, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

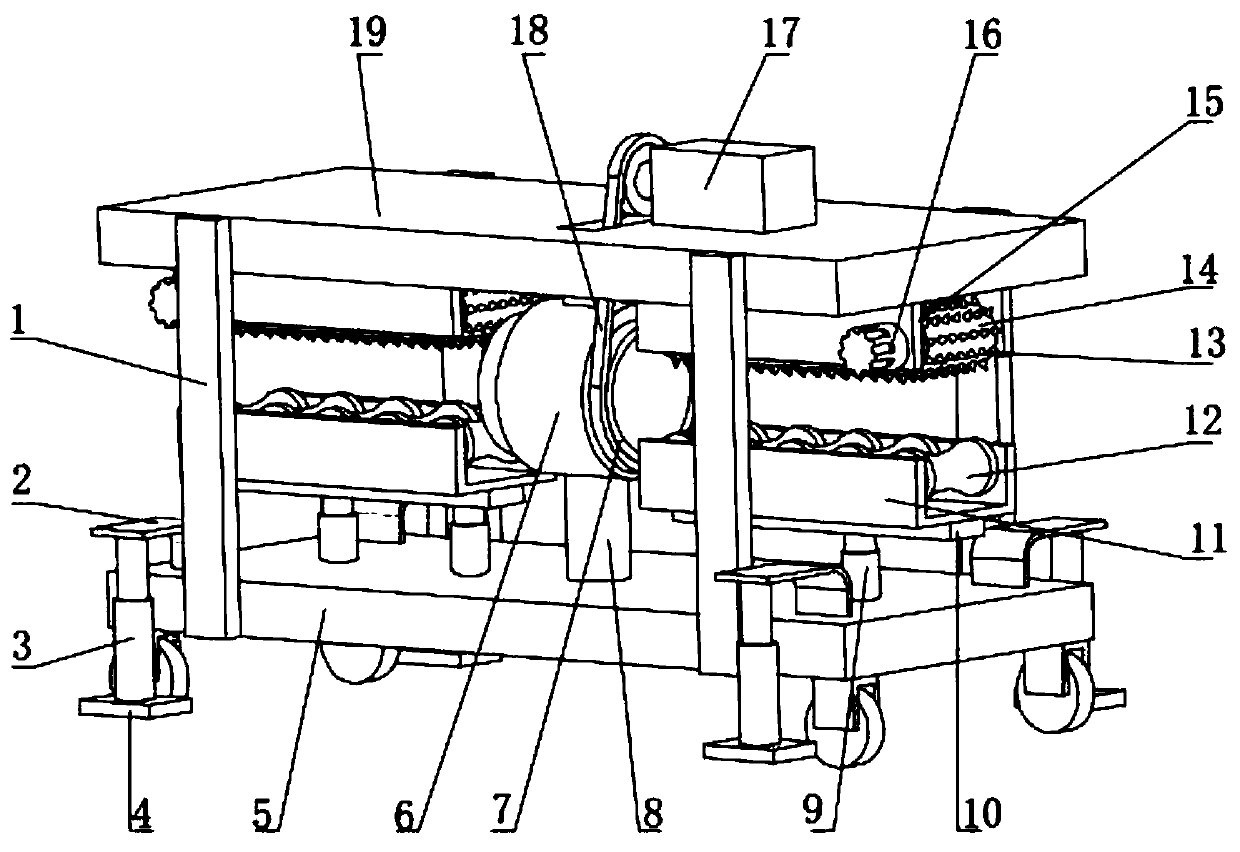

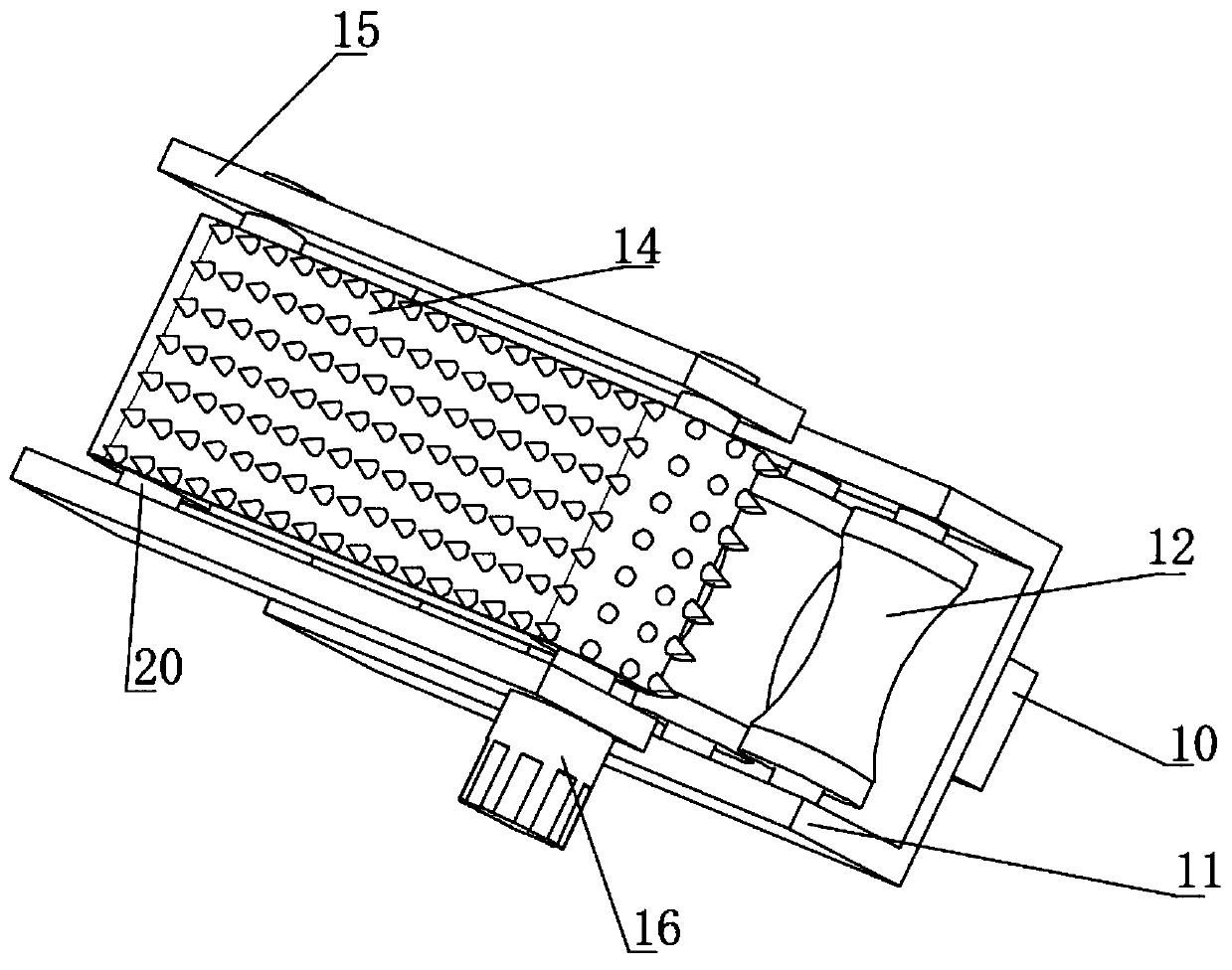

[0026] Reference Figure 1-3 , A log peeling device for wood processing, comprising an upper mounting plate 19 and a lower mounting plate 5. The top outer wall of the lower mounting plate 5 is equipped with first electric telescopic rods 9 on both sides, and two first electric telescopic rods 9 on the top outer wall The same first fixing plate 10 is installed, the top outer wall of the first fixing plate 10 is installed with a connecting frame 11, and the inner walls of the two ends of the connecting frame 11 are rotatably connected with arc-shaped squeezing rollers 12 distributed at equal distances, and the bottom outer wall of the upper mounting plate 19 A second fixing plate 15 is installed on both ends of the two second fixing plates 15 and the outer walls of the opposite ends of the two second fixing plates 15 are rotatably connected to both sides of the rotating shaft 20, and the outer wall of the two rotating shafts 20 is sleeved with the same conveyor belt 14 , The outer...

Embodiment 2

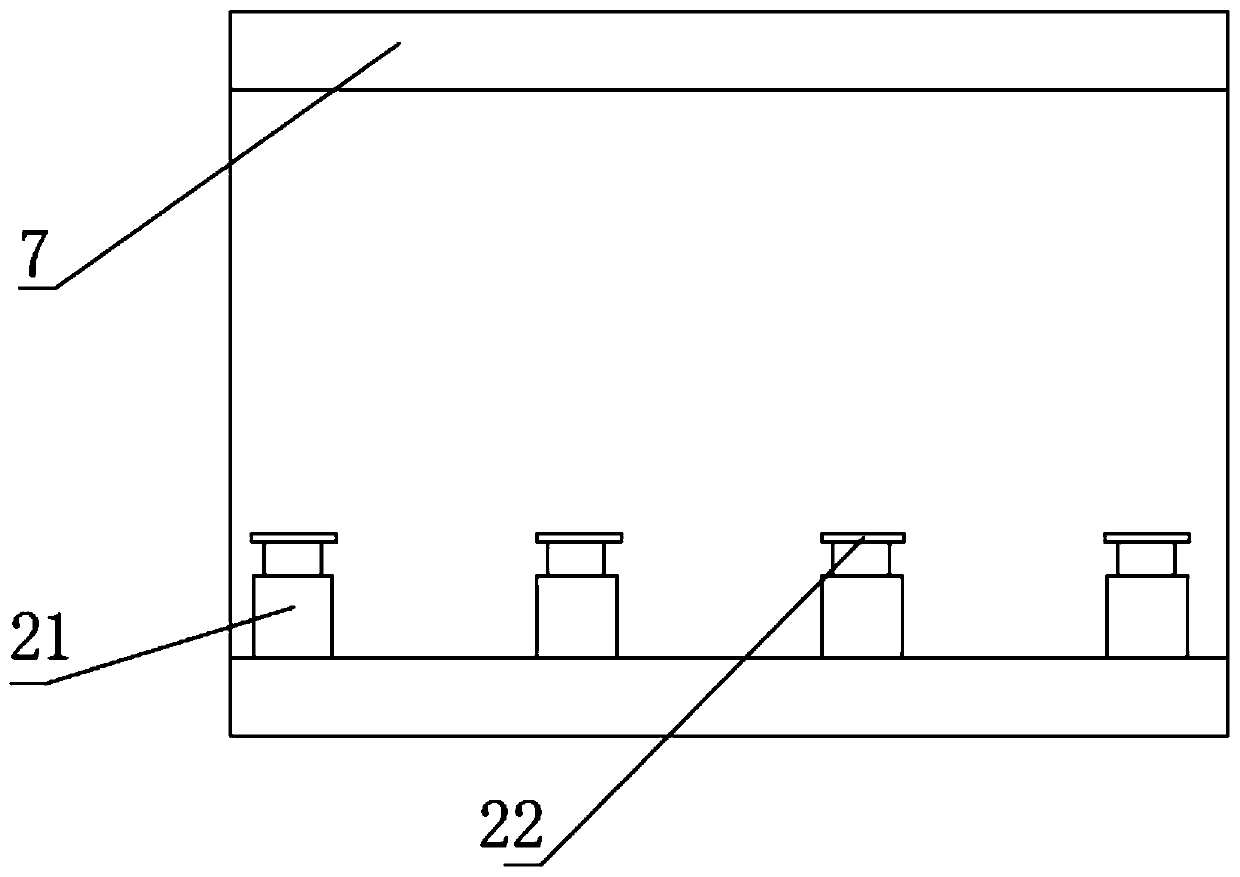

[0030] Reference Figure 1-4 , A log peeling device for wood processing, further comprising a first fixed plate 10 and a connecting frame 11 fixedly connected to the first fixed plate 10 and the connecting frame 11 provided with a sliding block 23, the top outer wall of the sliding block 23 is connected to the connecting frame by bolts 11 The bottom outer wall is fixedly connected, the top outer wall of the first fixing plate 10 is provided with a sliding groove, the bottom outer wall of the sliding block 23 is equipped with equidistantly distributed telescopic springs 24, and the bottom outer wall of the telescopic spring 24 is fixedly connected to the bottom inner wall of the first fixed plate 10 by bolts .

[0031] Working principle: Compared with Embodiment 1, the sliding block 23 and the telescopic spring 24 can be provided to fix the log more firmly, avoid unevenness of the log surface and damage the device, and improve the safety of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com