Self-generating limp system and method for hybrid electric vehicle

A self-generating technology for hybrid electric vehicles, applied in hybrid electric vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of immature technology, short development time, imperfect matching between 48V system and the whole vehicle, etc., and achieve improvement Effects of user experience and vehicle quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

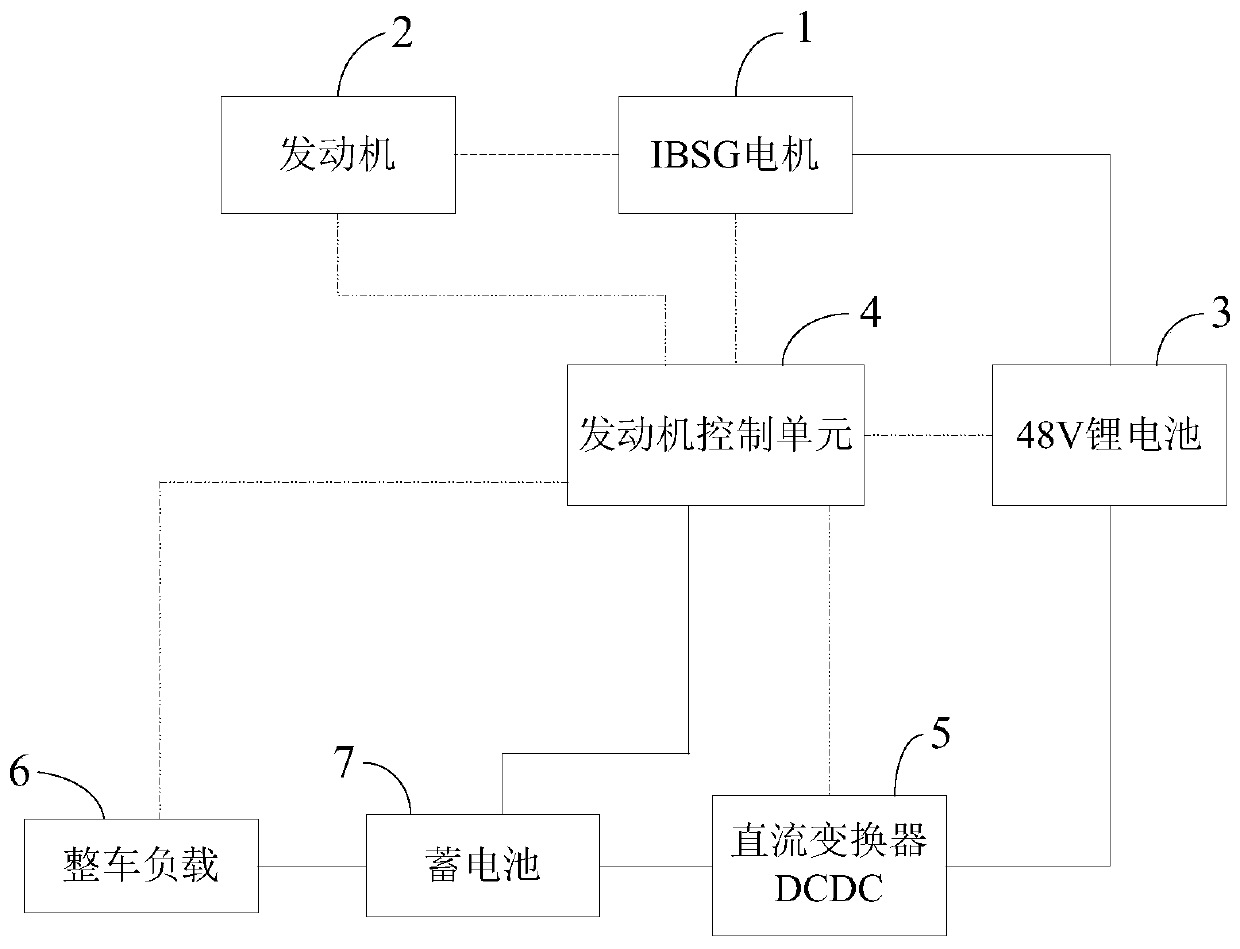

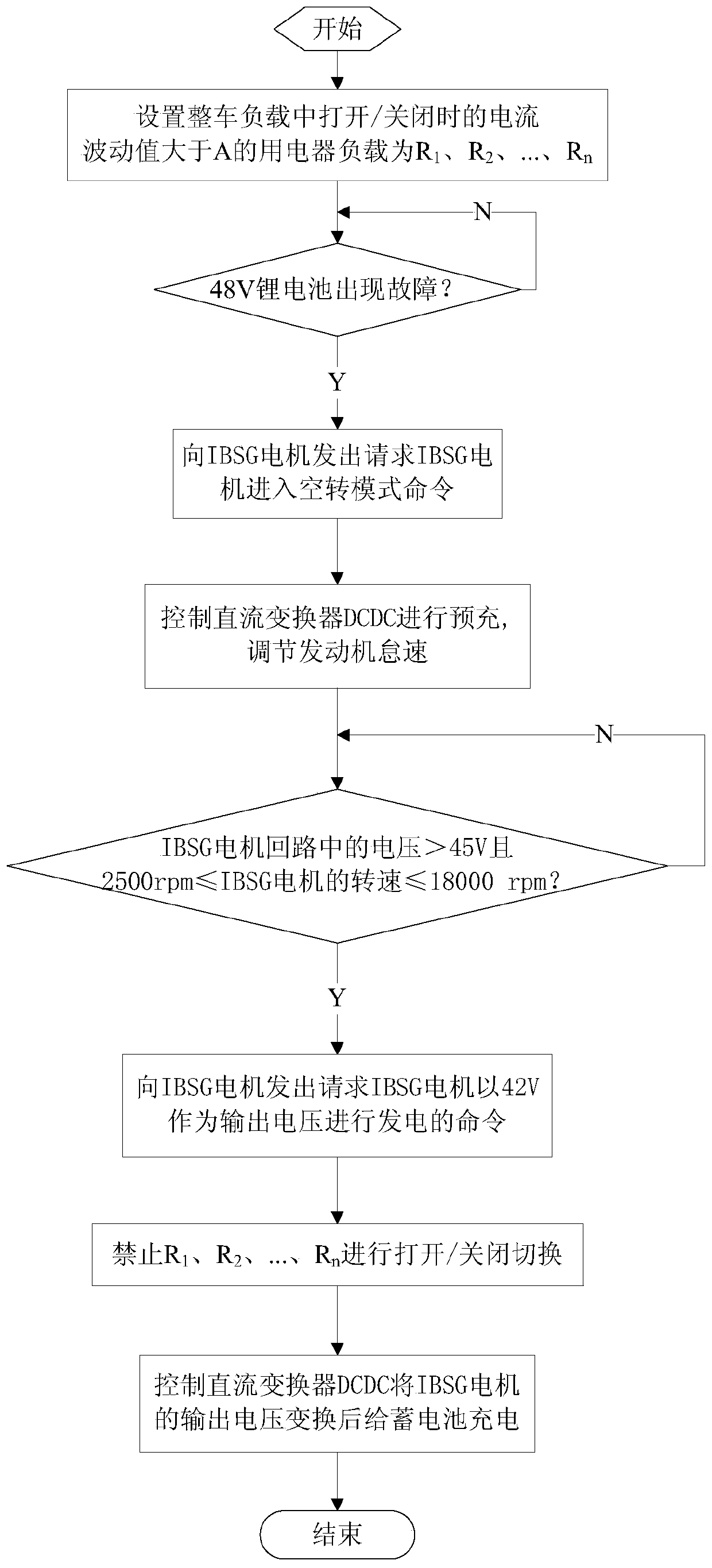

[0029] Such as figure 1 The self-generating limp system of a hybrid electric vehicle shown includes IBSG motor 1, engine 2, 48V lithium battery 3, engine control unit 4, DC converter DCDC5 and battery 7 (using 12V battery), engine control unit 4 and IBSG motor 1 , the engine 2, the 48V lithium battery 3, and the DC converter DCDC5 are respectively connected through signal lines, the battery 7 is connected with the engine control unit 4 through the power line, the battery 7 supplies power to the engine control unit 4, and the battery 7 is connected with the DC converter DCDC5 through the power line Connection, the DC converter DCDC5 is connected to the 48V lithium battery 3 through the power line, the IBSG motor 1 is connected to the engine 2, the IBSG motor 1 can rotate under the drive of the engine 2, and the IBSG motor 1 can also drive the flywheel of the engine 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com