Laser curve scale

A technology of laser and ruler, which is applied in the direction of sewing clothes tools, etc., to achieve the effect of improving the laser curve marking positioning process, making the processing and manufacturing simple and easy, and simplifying the laser measurement operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

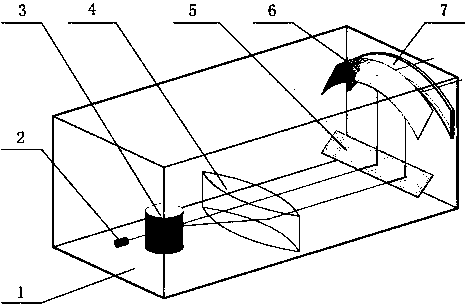

[0037] like figure 1 As shown, the laser source 2 is a point light source, and the optical assembly also includes a cylindrical reflector 3, a lens 4 and a plane reflector 5, and the laser light emitted by the point light source is expanded into laser light by the cylindrical reflector 3 The flat sheet light is converted into parallel laser light through the lens 4, and the parallel laser light passes through the plane reflector 5 to change its path, and then is reflected twice by the curved surface reflector 6 to form a ruled curved surface laser. Wherein, the reflective surface of the curved reflector 6 is a cylindrical surface, and a laser is used as a laser source. Therefore, in this embodiment, the laser ruled curved surface emitted from the laser outlet 7 is a cylindrical surface, and the ruled lines are consistent with the direction of the laser light emitted by the laser source 2 . In order to achieve the required accuracy of the ruled curved surface, the curved mirro...

Embodiment 2

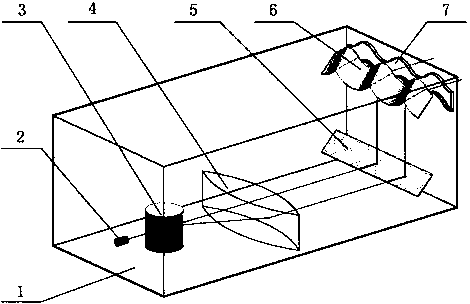

[0039] like figure 2 As shown, Embodiment 2 is basically the same as Embodiment 1, except that the reflective surface of the curved mirror 6 is a corrugated surface, so that the ruled curved surface of the laser emitted from the laser outlet 7 is a corrugated surface.

Embodiment 3

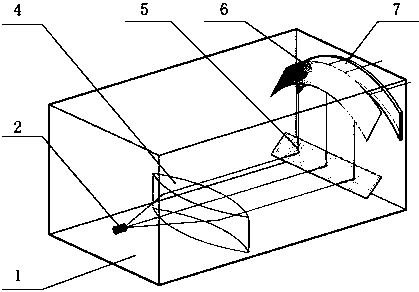

[0041] like image 3 As shown, embodiment 3 is basically the same as embodiment 1, the difference is that the cylindrical reflector 3 is removed, and the point light source 2 is directly positioned at the focal point of the lens 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com