A solid wood seamless bending process

A curved and seamless technology, which is applied in the direction of wood bending, wood processing equipment, manufacturing tools, etc., can solve problems such as difficult paint finishing, reduced strength of curved parts, rough curved surface, etc., to achieve a high degree of automation and reduce labor intensity , the effect of enhancing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

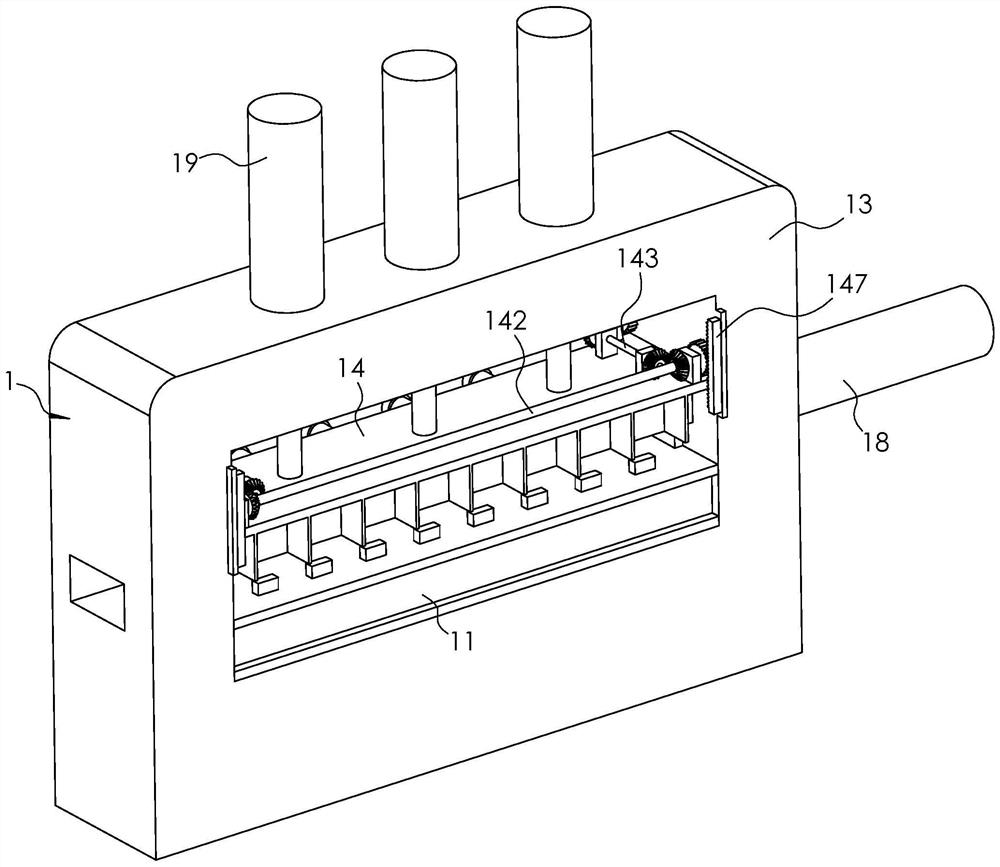

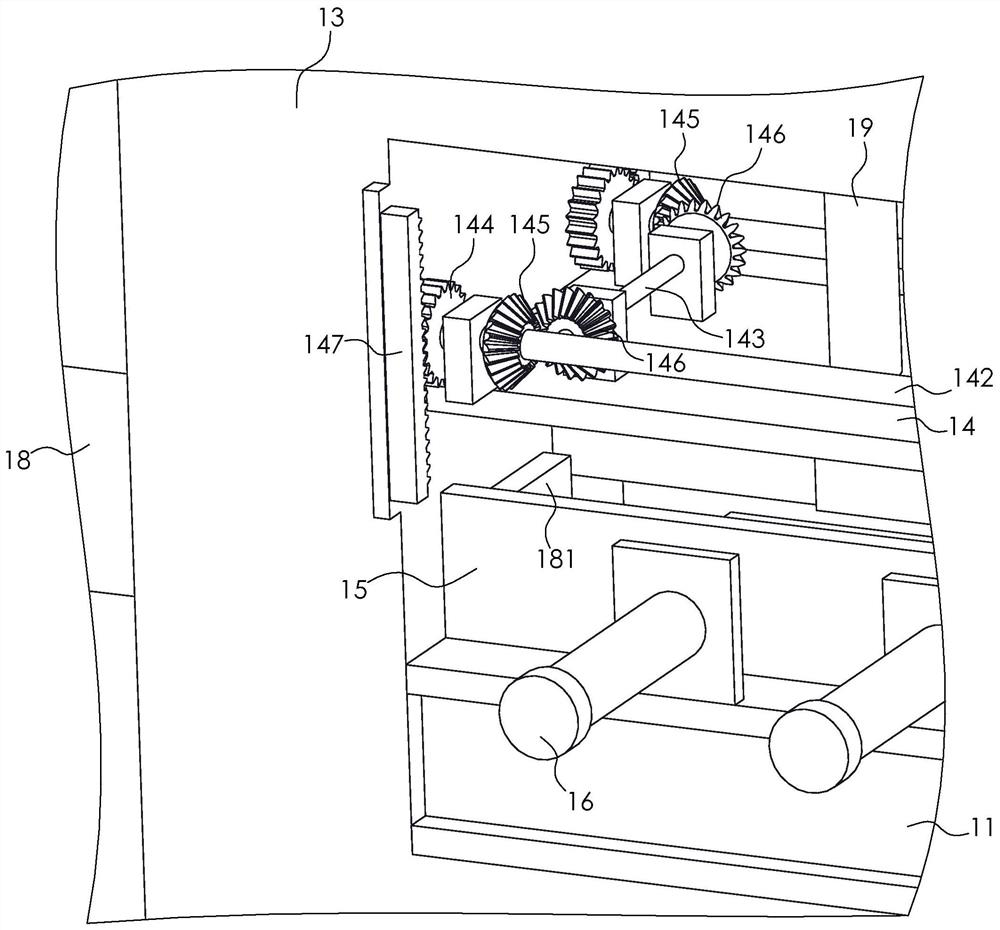

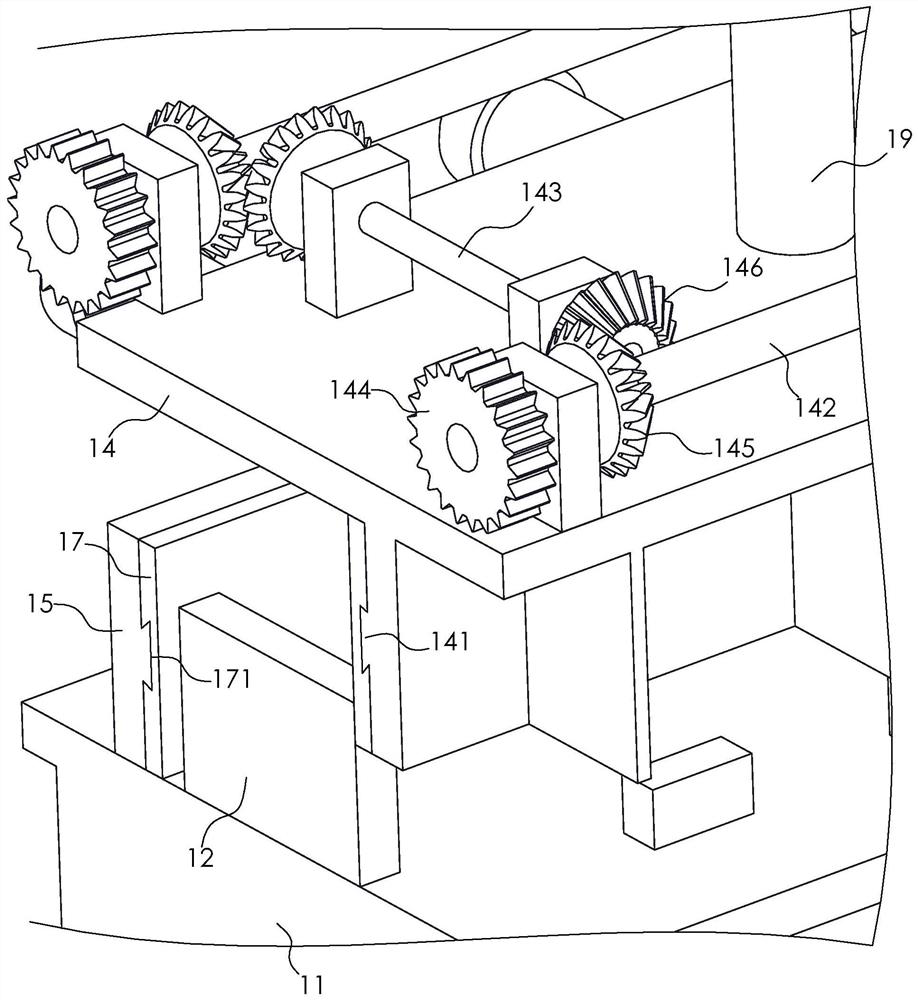

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] A solid wood seamless bending process, comprising the following steps:

[0039] S1. First put the wood into the airtight humidification barrel, the first air pump is installed on the airtight humidification barrel, the pressure sensor is installed in the airtight humidification barrel, and the water tank and processor are placed outside the airtight humidification barrel. The barrels are connected, the pipeline is equipped with a water valve, and the first air pump, the water valve and the pressure sensor are all coupled to the processor.

[0040] Firstly, the air in the airtight humidifying barrel is pumped out by the first air pump, so that a negative pressure with a pressure value of 0.075-0.085Mpa is formed in the airtight humidifying barrel, and the optimal pressure value in the airtight humidifying barrel is 0.085Mpa, so that the gas in the wood ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com