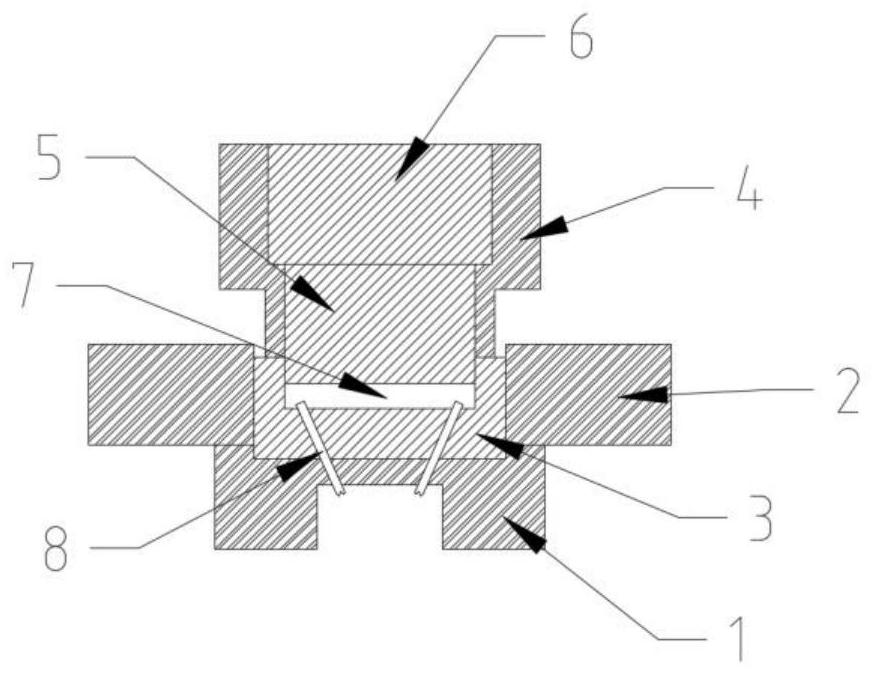

High-voltage electric appliance contact finger part cold extrusion forming technology and die thereof

A technology for high-voltage electrical appliances and forming processes, applied in metal extrusion dies, electrical components, metal material coating processes, etc., can solve the problems of insufficient filling at the ear making, difficulty in forming finger parts, and low material utilization. Achieve the effect of easy molding, stable mechanical properties and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

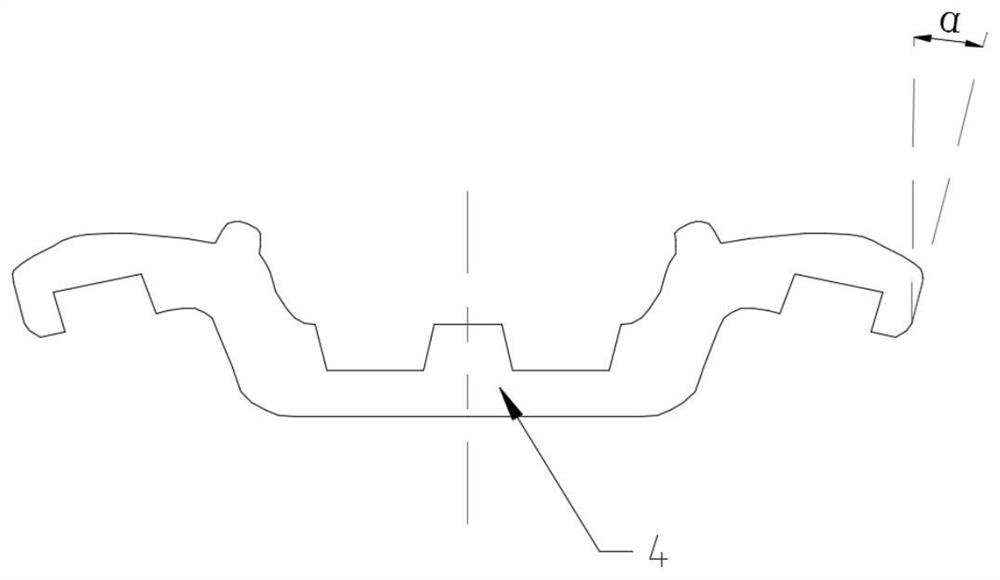

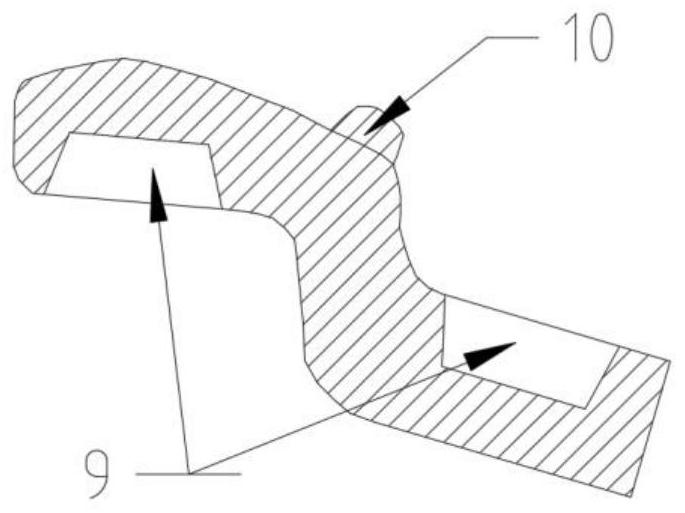

[0046] Embodiment 1: Using a mold of a cold extrusion forming process for high-voltage electrical contact finger parts to prepare contact finger parts, wherein the draft angle of the cavity 7 is 2.5°, including the following steps:

[0047]S1. Material selection and cutting: Select T2 red copper that matches the target size of the finger parts, cut it, and the volume is 1021mm 3 ;

[0048] S2. Annealing treatment:

[0049] 1) The first heating and holding stage: the temperature is raised from room temperature to 200°C, the heating rate is 3°C / min, and the holding time is 3h;

[0050] 2) The second heating and holding stage: from the first heating and holding stage to 390°C, the heating rate is 2.2°C / min, and the holding time is 3.5h;

[0051] 3) Cooling: take out after cooling to 65°C from the second heating and holding stage;

[0052] S3. Phosphating treatment:

[0053] 1) Phosphating treatment: place the blank in a phosphating solution for phosphating, the phosphating ti...

Embodiment 2

[0061] Embodiment 2: Using a mold of a cold extrusion forming process for high-voltage electrical contact finger parts to prepare contact finger parts, wherein the draft angle of the cavity 7 is 2.2°, including the following steps:

[0062] S1. Material selection and cutting: Select T2 red copper that matches the target size of the finger parts, cut it, and the volume is 1021mm 3 ;

[0063] S2. Annealing treatment:

[0064] 1) The first heating and holding stage: the temperature is raised from room temperature to 180°C, the heating rate is 2.4°C / min, and the holding time is 2.5h;

[0065] 2) The second heating and holding stage: from the first heating and holding stage, the temperature is raised to 370°C, the heating rate is 2°C / min, and the holding time is 3h;

[0066] 3) Cooling: take out after cooling to 50°C from the second heating and holding stage;

[0067] S3. Phosphating treatment:

[0068] 1) Phosphating treatment: place the billet in a phosphating solution for ...

Embodiment 3

[0076] Embodiment 3: Using a mold of a cold extrusion forming process for high-voltage electrical contact finger parts to prepare contact finger parts, wherein the draft angle of the cavity 7 is 2.8°, including the following steps:

[0077] S1. Material selection and cutting: Select T2 red copper that matches the target size of the finger parts, cut it, and the volume is 1021mm 3 ;

[0078] S2. Annealing treatment:

[0079] 1) The first heating and holding stage: the temperature is raised from room temperature to 220°C, the heating rate is 3.6°C / min, and the holding time is 3.5h;

[0080] 2) The second heating and holding stage: from the first heating and holding stage to 420°C, the heating rate is 2.4°C / min, and the holding time is 4h;

[0081] 3) Cooling: take out from the second heating and holding stage after cooling to 80°C;

[0082] S3. Phosphating treatment:

[0083] 1) Phosphating treatment: place the billet in a phosphating solution for phosphating, the phosphat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Draft angle | aaaaa | aaaaa |

| Draft angle | aaaaa | aaaaa |

| Draft angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com