Method for installing composite cable saddle in anchor hole of a mountainous area suspension bridge tunnel s

An installation method and tunnel anchor technology, which are applied to suspension bridges, bridges, bridge parts, etc., can solve the problems of insufficient installation of composite cable saddle tunnel anchor holes, and achieve the effects of reducing construction costs, convenient operation and less equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

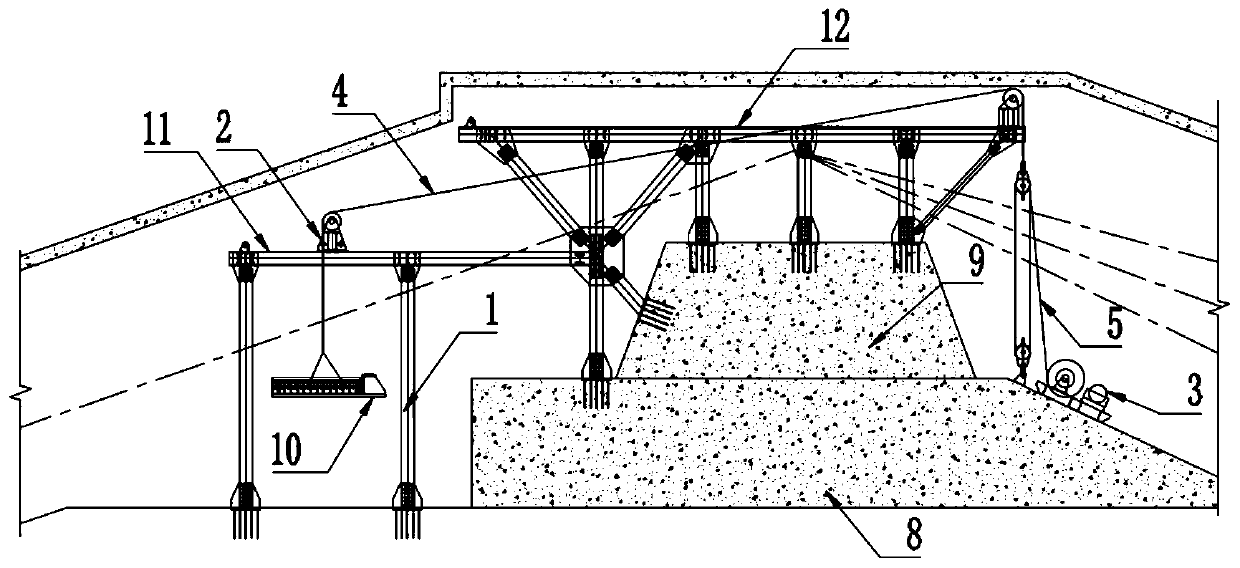

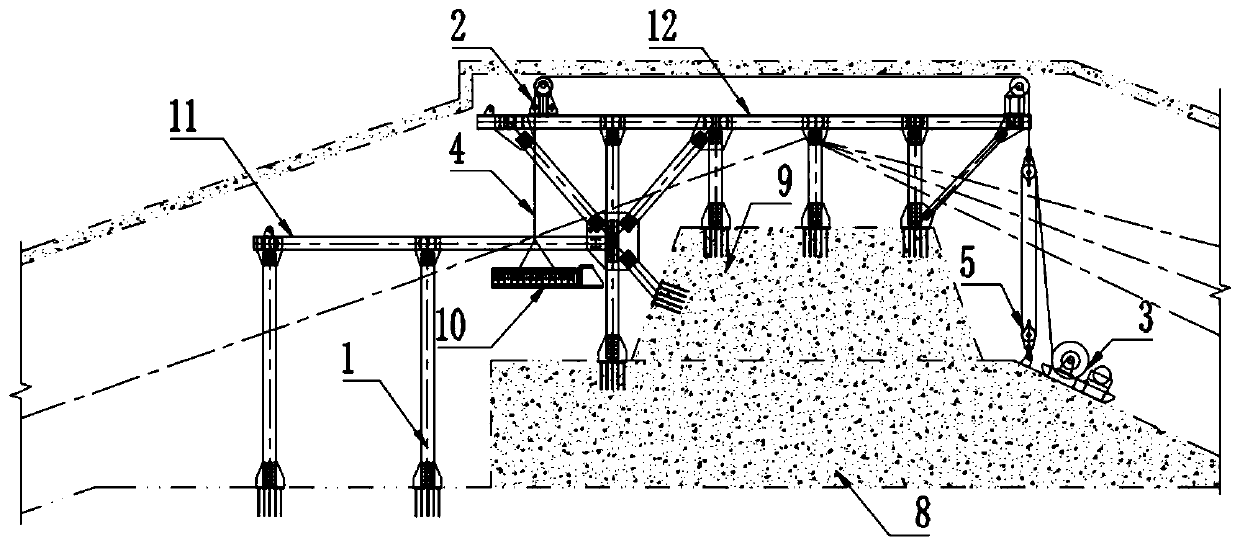

[0050] see figure 1 with Image 6 As shown, the embodiment of the present invention provides a method for installing a composite cable saddle in the tunnel anchor hole of a suspension bridge in a mountainous area. The composite cable saddle pier foundation 8 and the composite cable saddle pier 9 for installing the composite cable saddle are arranged in the tunnel anchor hole. The pier 9 is located on the top of the composite cable saddle pier foundation 8 . The elevation from the opening of the tunnel anchor hole to the top of the composite cable saddle pier 9 gradually increases, a portal frame 1 is set above the composite cable saddle pier foundation 8, and a hoist 3 is arranged behind the composite cable saddle pier foundation 8 . This method comprises the following steps:

[0051] Step 1: Use a flatbed truck to transport the component 10 of the composite cable saddle to the side of the pier foundation 9 of the composite cable saddle. Due to the excessive weight of the c...

Embodiment 2

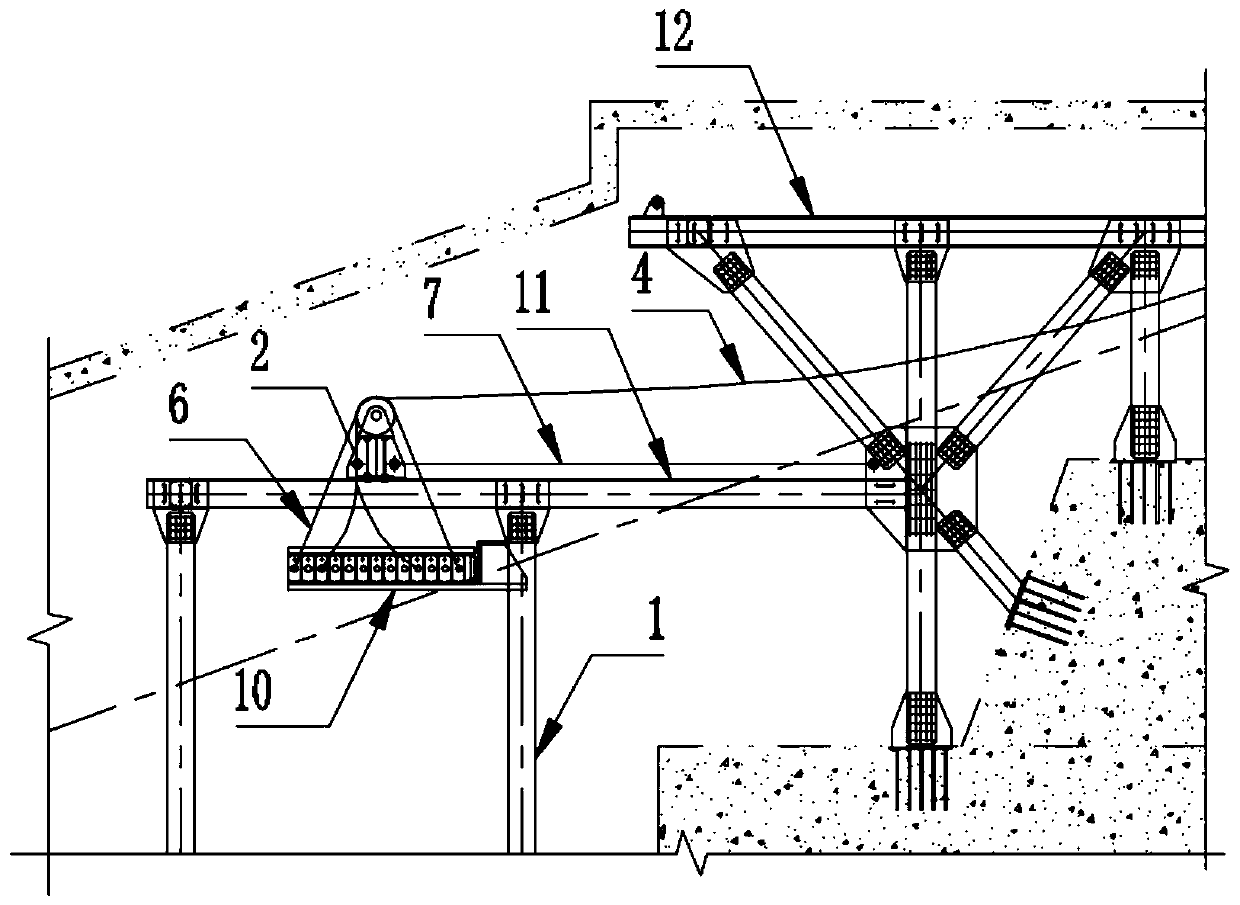

[0062] see figure 1 , Figure 9 with Figure 10 As shown, on the basis of Embodiment 1, the embodiment of the present invention provides a method for installing a composite cable saddle in the anchor hole of a suspension bridge tunnel in a mountainous area. The steering device 22 bypassing the sliding seat 2 on the platform 11 is connected to the component 10 of the composite cable saddle, and the steel plate 26 is placed between the sliding seat 2 and the mast 1 to fix the sliding seat 2 on the first elevation platform of the mast 1 11 to prevent the sliding seat 2 from overturning on the first elevation platform 11 of the portal frame 1 . The hoist 3 is started, and the hoisting wire rope 4 passes through the hoist 3 to lift the component 10 of the composite cable saddle to be higher than the top surface of the composite cable saddle pier foundation 8 .

[0063] By setting the sliding seat 2 on the first elevation platform 11 of the portal frame 1, the steering device 22 ...

Embodiment 3

[0065] see figure 1 with Figure 11 As shown, on the basis of Embodiment 2, the embodiment of the present invention provides a method for installing a composite cable saddle in the anchor hole of a suspension bridge tunnel in a mountainous area. The difference between this method and Embodiment 2 is that the first elevation platform 11 of the portal frame 1 is located at Close to the opening of the tunnel anchor hole, since the elevation from the opening of the tunnel anchor hole to the top of the composite cable saddle pier 9 gradually increases, the first elevation platform 11 located at the portal frame 1 of the tunnel anchor hole is compared with the first elevation platform 11 located at the composite cable saddle pier. The height of the second elevation platform 12 of the portal frame 1 above the foundation 8 is slightly lower. The hoist 3 is arranged at the rear of the composite cable saddle pier foundation 8 away from the tunnel anchor hole, and the hoist 3 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com