Construction method of height-adjustable safety guardrail device

A technology of safety guardrails and construction methods, which is applied in the directions of excavation, infrastructure engineering, and construction material processing, etc., which can solve problems such as increased safety risks at high-altitude borders, lack of protective measures, and obstacles to the normal use of mechanical equipment, so as to avoid borders Effects of operating status, safe return to normal height, and increased height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

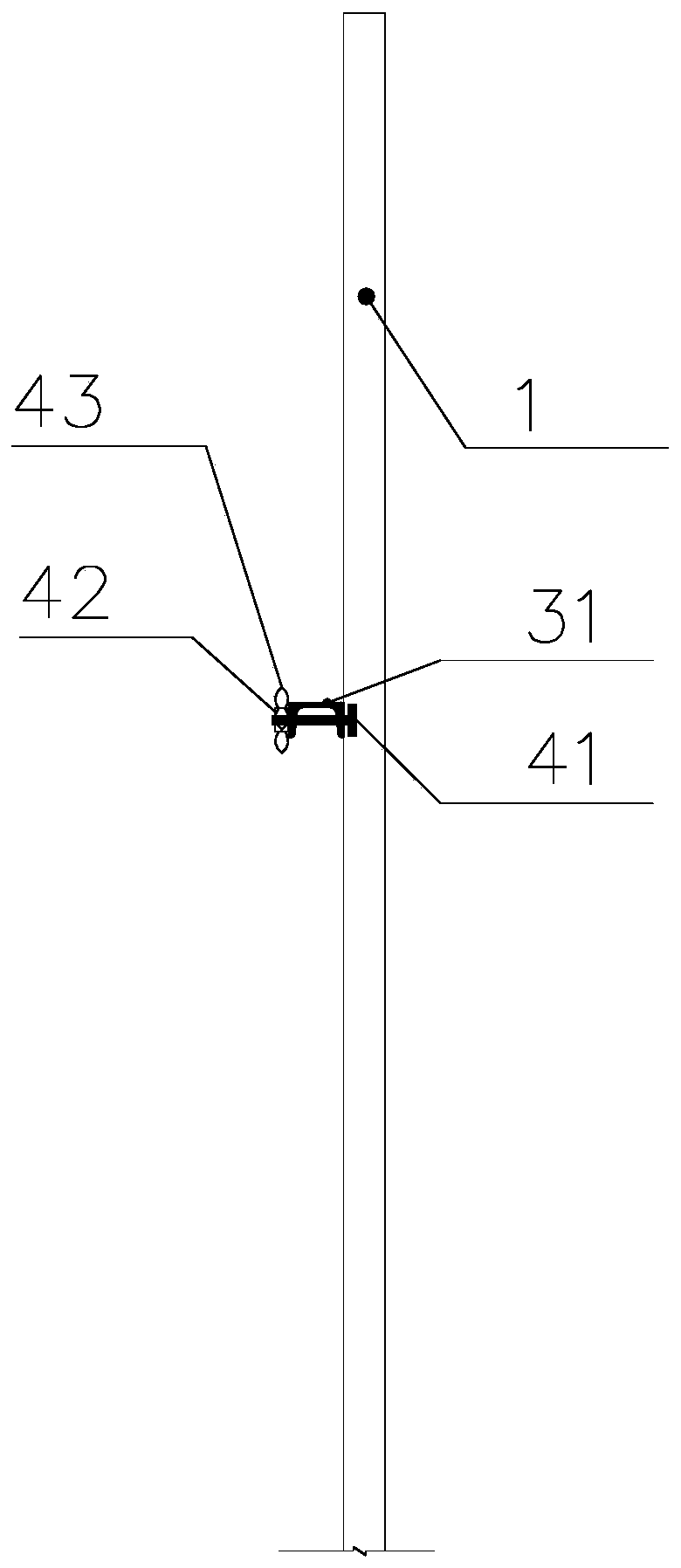

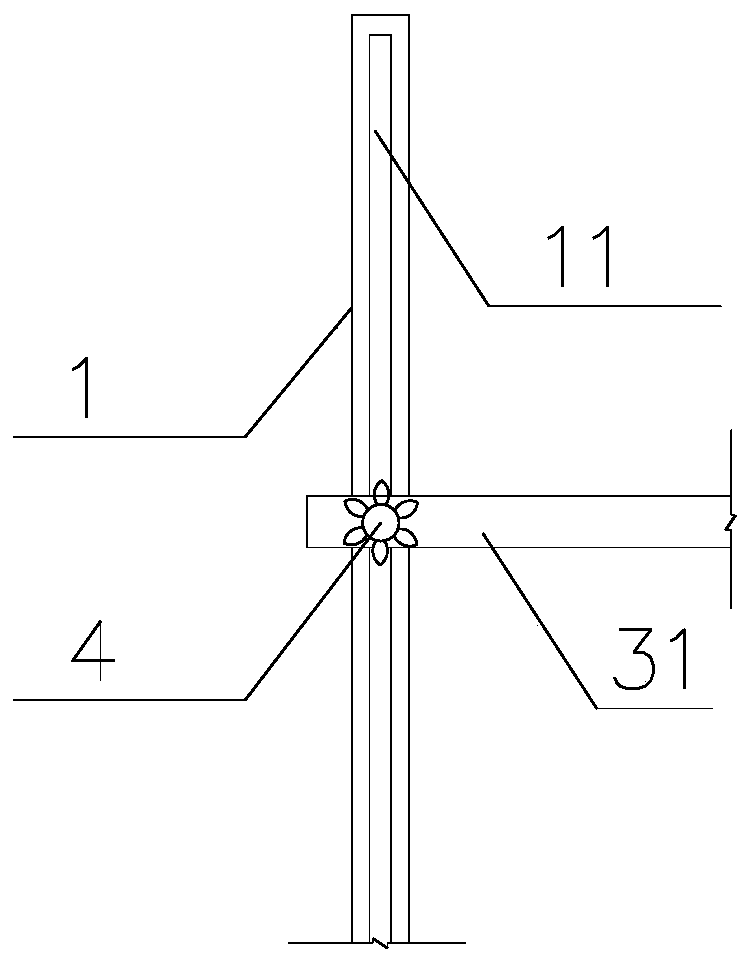

[0048] see Figure 7 to Figure 10 , the difference between this embodiment and Embodiment 1 is:

[0049] The height locking mechanism of the guardrail includes a screw rod 44, a nut 42 and an anti-rotation block 45. A vertical chute 11 is provided on the fixed column, and the upper rail 31 of the movable guardrail is provided with a through hole for the bolt rod of the bolt 41 to pass through. One end of the screw rod 44 is fixedly connected to the anti-rotation block 45, and the other end of the screw rod 44 passes through the vertical chute 11 of the fixed column 1 and the through hole of the upper rail 31 of the movable guardrail in sequence, and passes through the The nut 42 is fixed, the anti-rotation block 45 is located inside the fixed column 1 , and the fixed column 1 can limit the rotation of the anti-rotation block 45 around the axis of the screw rod 44 inside the fixed column 1 .

[0050] The anti-rotation block, on the one hand, can be used as a limiting device to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com