A high stability stainless steel corrugated hose wall outlet device for gas transmission

A corrugated hose, stainless steel technology, applied in the direction of pipes, pipe supports, pipes/pipe joints/fittings, etc., can solve the problems of gas leakage, no public clamping and supporting equipment, low reliability and aesthetics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

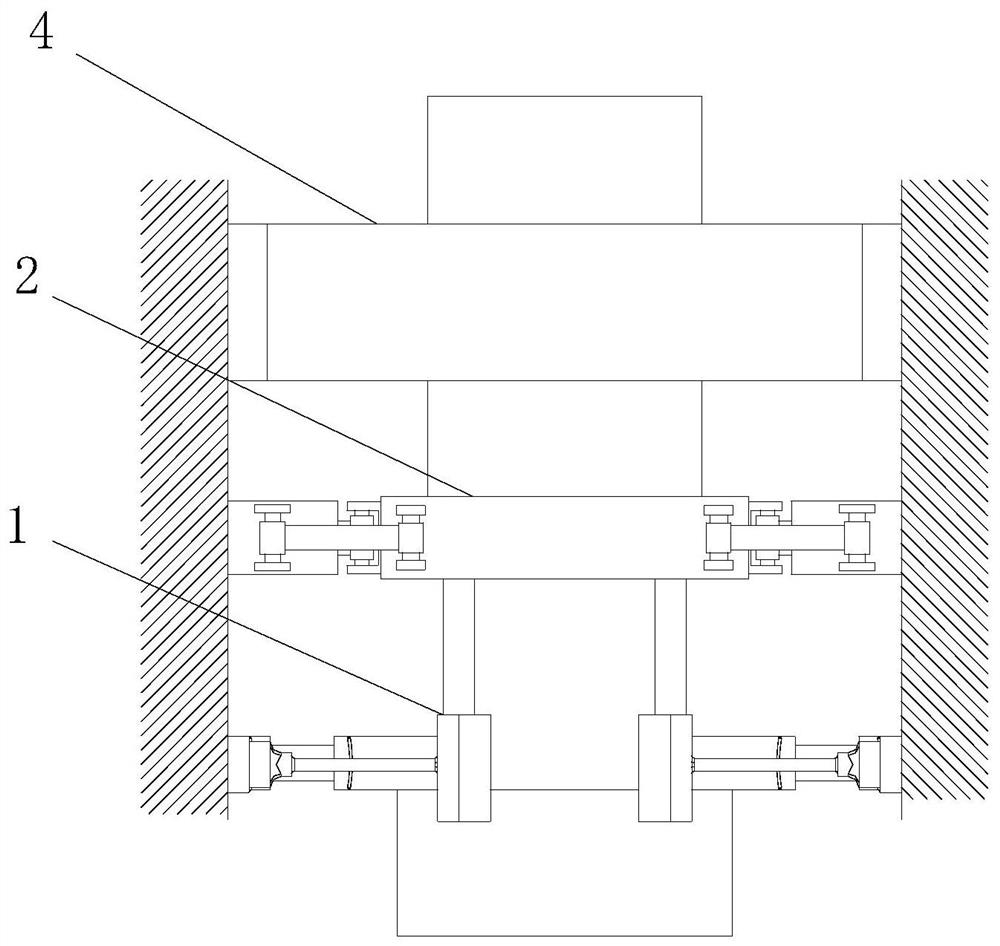

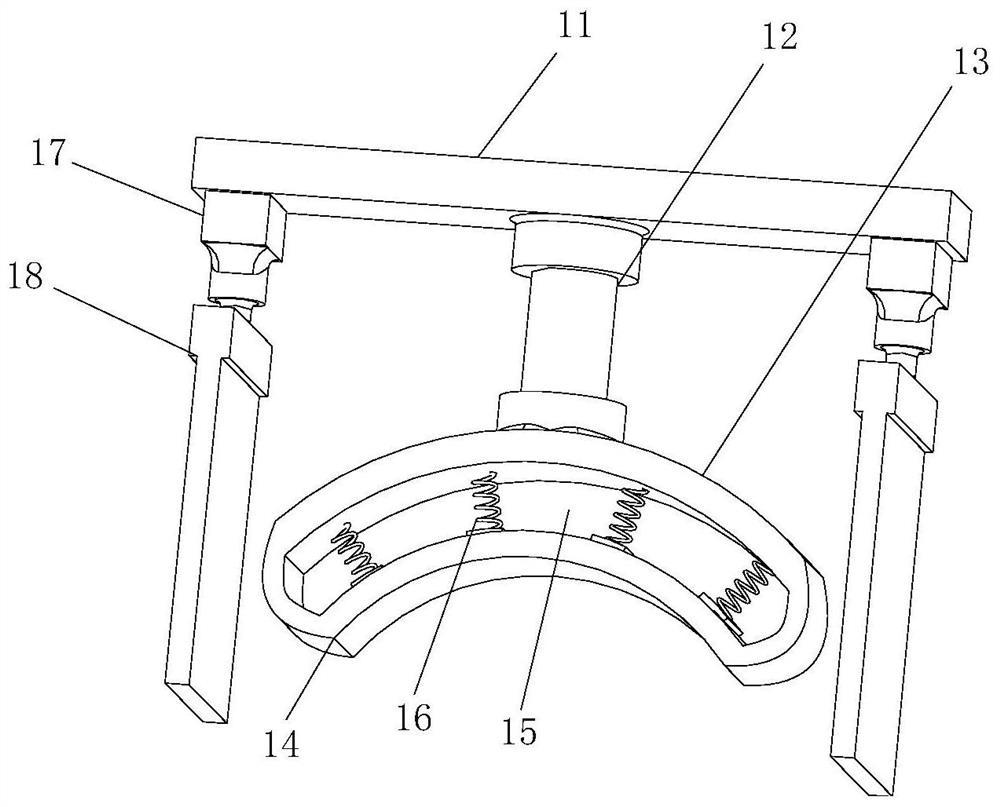

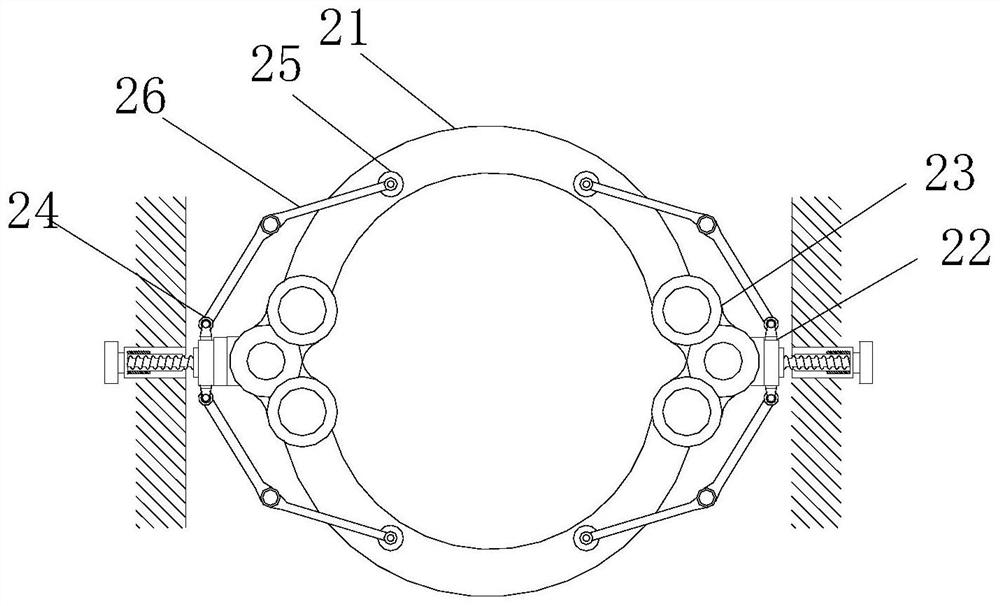

[0035] see figure 1 and figure 2 , a high-stability stainless steel corrugated hose outlet device for gas transmission, including a support frame 1, a clamping frame 2 and a limit frame 4, and side support plates 11 are installed on the two side walls of the wall. A support rod 12 is installed on the board 11, a support pad 13 is installed on the support rod 12, the support pad 13 has an arc structure, and the main body of the support pad 13 is an arc plastic pad 14. The pad 14 has an inner hollow structure and is provided with an inner slot 15 , and a plurality of support springs 16 are installed in the inner slot 15 in a supporting manner. Side fixing plates 17 are installed on both sides of the side support plate 11, and screw hole fixing plates 18 are installed on the side fixing plates 17.

[0036] In the present application, a support mechanism is provided at the end of the stainless steel corrugated hose into the wall, and a support frame 1 is provided on both sides ...

Embodiment 2

[0043] see Figure 5 , Figure 7 and Figure 8 , this embodiment is a further optimization of the first embodiment. On the basis of this, a transmission disc 51 is installed at the bottom of the limit frame 4, and a spiral groove 52 is arranged on the top disc surface of the transmission disc 51. The grooves 52 are spirally arranged on the drive plate 51 , a movable bracket 53 is installed at the bottom of the fixed rod 43 , the bottom plate of the movable bracket 53 is provided with helical teeth, and the movable bracket 53 is fitted and installed by the helical teeth Between the helical grooves 52 , the edge of the bottom disk surface of the transmission disc 51 is provided with transmission tooth grooves 54 , and the bottom of the transmission disc 51 is provided with a transmission gear 55 , and the transmission gear 55 engages with the transmission tooth grooves 54 . The side of the limit frame 4 is provided with an adjustment shaft, the driving end of the adjustment sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com