Cooling device for at least one component mounted on printed circuit board and printed circuit board

A technology for printed circuit boards and cooling devices, which is applied in the directions of printed circuit components, printed circuits, printed circuits, etc., can solve problems such as increasing the installation workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

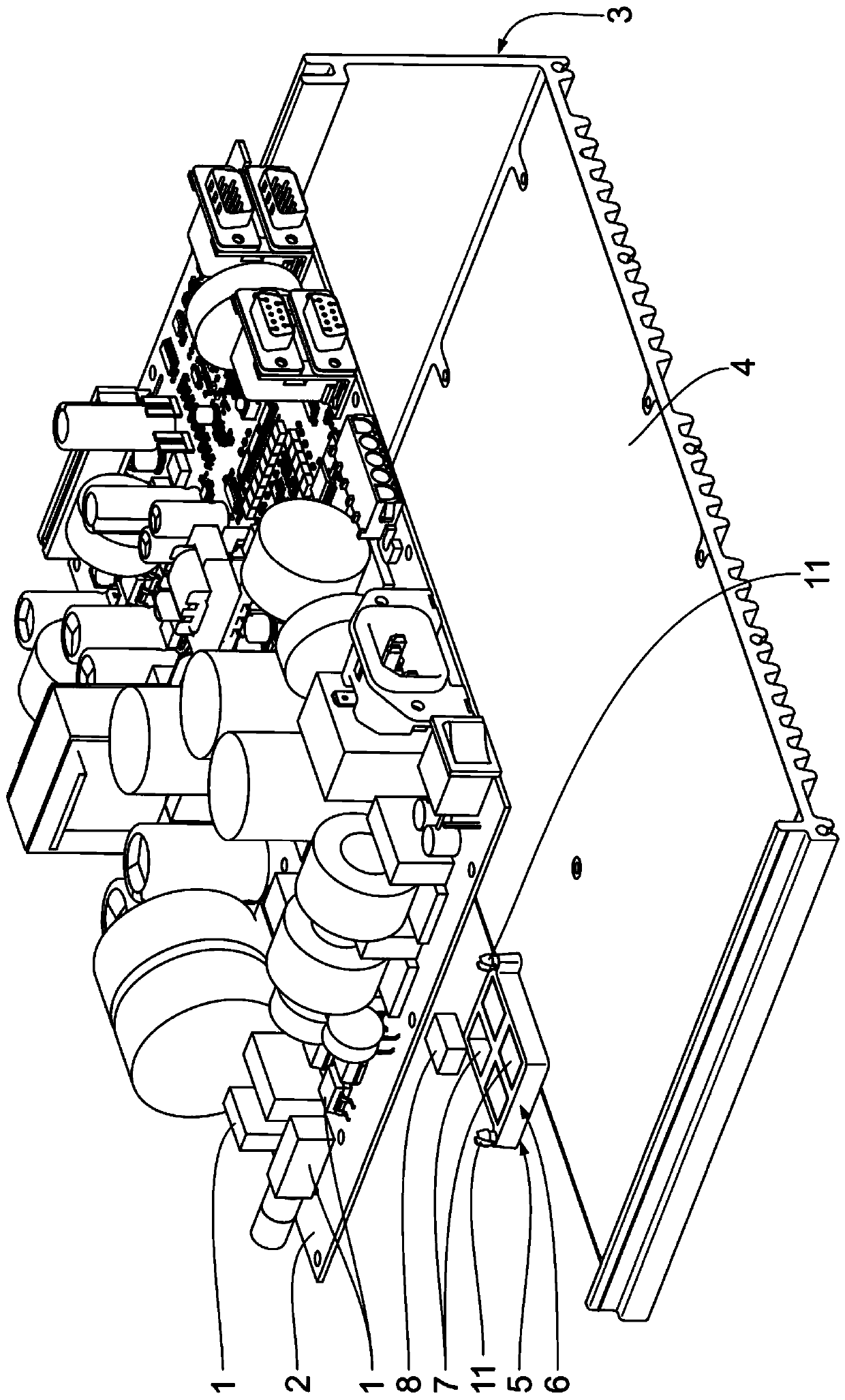

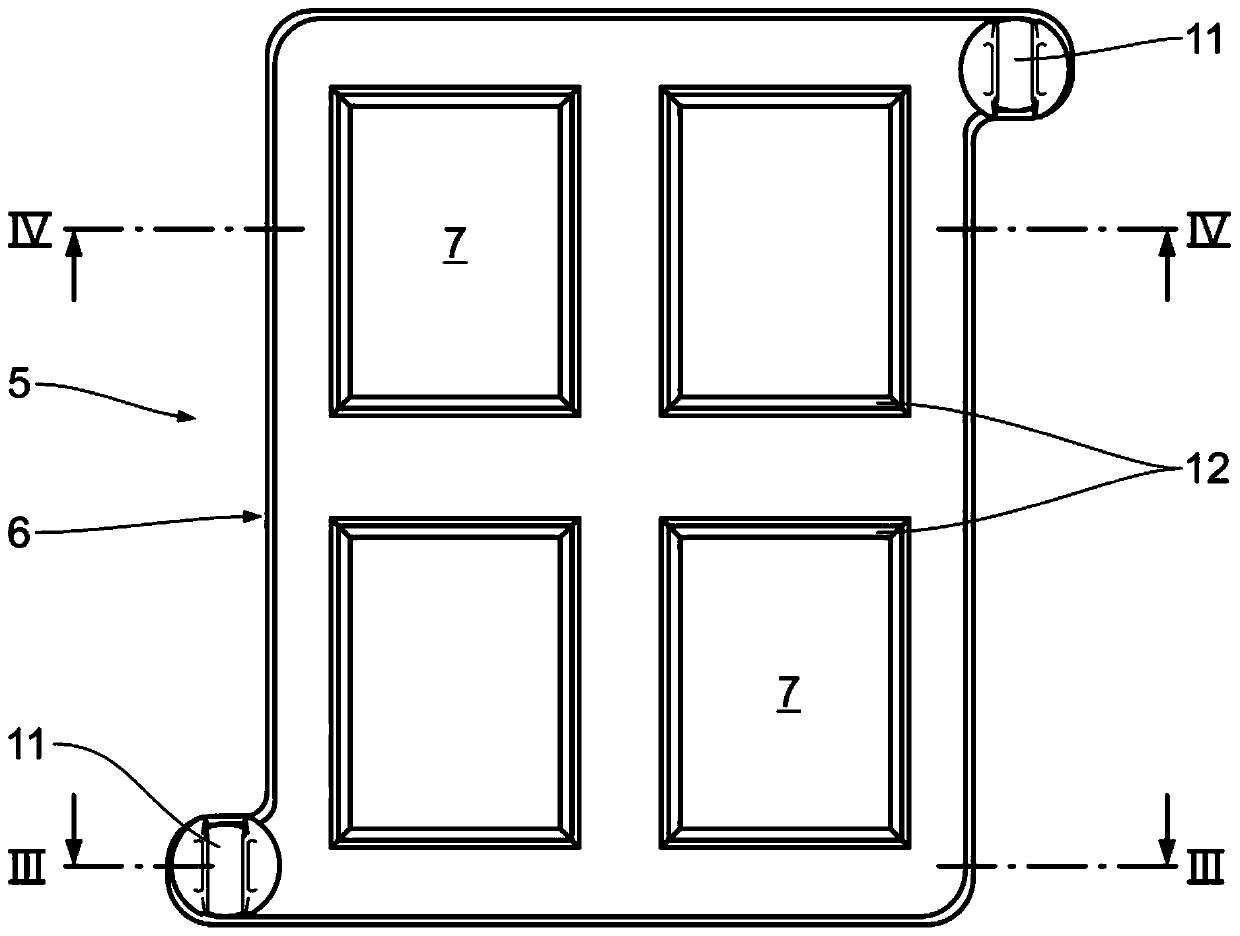

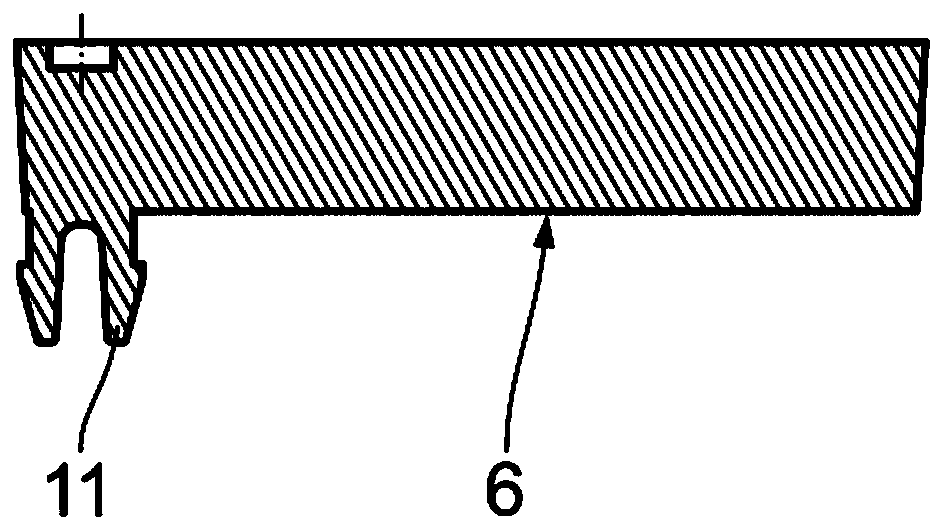

[0029] figure 1 A printed circuit board 2 equipped with various SMD components 1 and a metal housing 3 for receiving the printed circuit board 2 are shown in an exploded view. exist figure 1 , the components of the cooling device collectively designated 5 are arranged between the printed circuit board 2 and the bottom housing wall 4 of the metal housing 3 . The cooling device 5 serves to cool at least one of the components 1 mounted on the printed circuit board 2 . The cooling device 5 , as a heat conducting element frame, has a plastic heat sink frame 6 which includes four heat sink receptacles 7 as heat conducting element receptacles. The plastic material of the heat sink frame 6 is fireproof, electrically insulating, heat-resistant and shape-fixed.

[0030] The heat sink receptacle 7 is arranged complementary to the cuboid metal heat sink 8, one of which is in the figure 1 shown in . The metal cooling body 8 serves as a heat conducting element. The metal heat sink 8 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com