Cotton tip pruning method based on tracked robot

A robot and crawler-type technology, applied in the field of cotton topping based on crawler robots, can solve problems such as harsh working environment, low topping efficiency, and affecting cotton farmers' enthusiasm for planting, and achieve the effect of solving low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

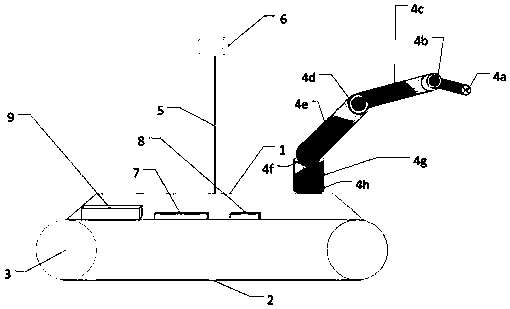

[0051] The cotton topping method based on crawler robot provided in this embodiment is a method for cotton topping applied to crawler robot, wherein, as figure 2 As shown, the crawler robot includes: a body 1, crawler belts 2 on both sides below the chassis of the vehicle body 1, with the forward direction of the robot as the positive direction, and the stepper motor 3 driven by the rear of the crawler belt 2 to move the robot, so Describe the four-degree-of-freedom mechanical arm 4 at the front of the vehicle body 1, the cylindrical cutter device 4a at the forward claw head of the mechanical arm 4, the automatic lifting rod 5 in the middle of the vehicle body 1, and the automatic lifting rod 5 in the middle of the vehicle body 1. The binocular camera 6 on the pole top position, the core control board 7 and the motor drive board 8 inside the vehicle body, and the battery module 9 at the rear of the vehicle body 1 .

[0052] Such as figure 2 As shown, the mechanical arm 4 in...

Embodiment 2

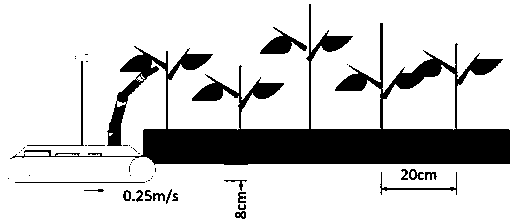

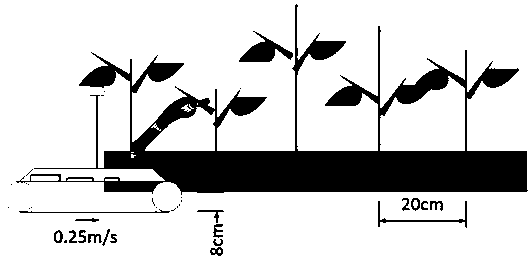

[0086] In this embodiment, five pots of cotton plants with soil randomly excavated in the test field are arranged in a row, and the cotton topping method based on the crawler robot is described in detail. The specific process is as follows Figure 5 shown, including:

[0087] Arrange the cotton plants planted in the pots in a vertical row with a distance of 20 cm, and place the crawler robot on the right side of the cotton plants placed side by side with a distance of 8 cm, such as image 3 shown;

[0088] 1. Measure the height of the five pots of cotton plants before topping and record the height data before topping, adjust the initial height of the automatic lifting rod 5 so that the binocular camera 6 is at the level of the cotton plants, and obtain the first pot of cotton plant through the binocular camera 6 The image information of the upper branches and leaves is sent to the image processing device of the core control board 7 for processing;

[0089] 2. After obtaining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com