Bearing ring surface defect detection device based on machine vision

A technology for detection of bearing rings and defects, applied in sorting and other directions, can solve the problems of low detection efficiency and failure to realize on-site application in production lines, etc., achieve fast and stable results, save detection time, and flexibly adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

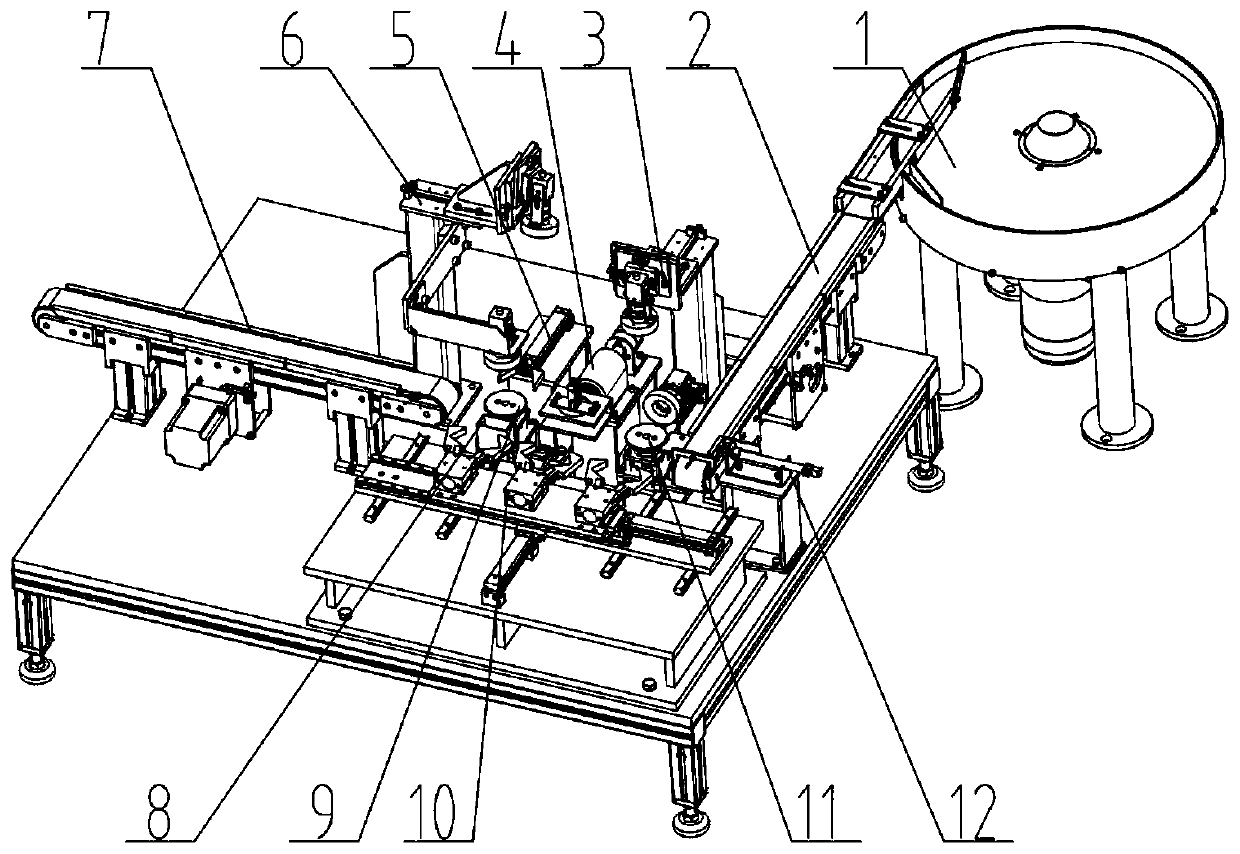

[0038] Such as figure 1 As shown, a kind of bearing ring surface defect detection device based on machine vision of the present invention mainly comprises: disk feeder 1, belt conveyor 2, push mechanism 12, first station rotary table 11, first station Camera adjustment frame 3, grabbing mechanism 10, flipping mechanism for the second station 4, rotary table for the third station 9, camera adjustment frame for the third station 6, rejecting mechanism 5, end belt conveyor 7, defective materials Road 8.

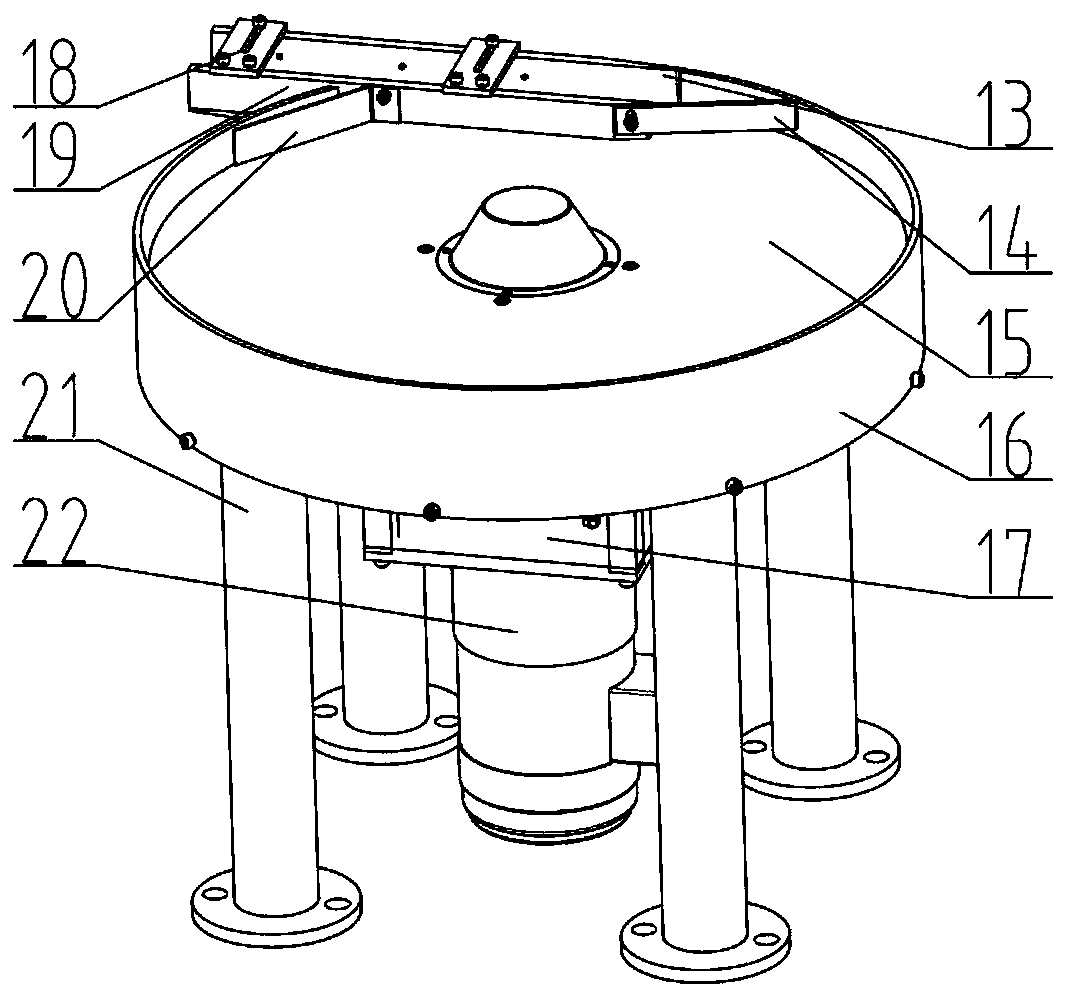

[0039] Such as figure 2 As shown, the disc feeding machine 1 mainly includes: a motor one 22, a motor support one 17, a supporting column 21, a disc bottom plate 15, a disc side plate 16, an inlet rib 14, and an outer side rib 13 of the material path , feedway inboard sidewall 19, feedway widening upper plate 18, small sidewall 20. The motor one 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com