Strong-radiation-resistance fiber pile and preparation process thereof

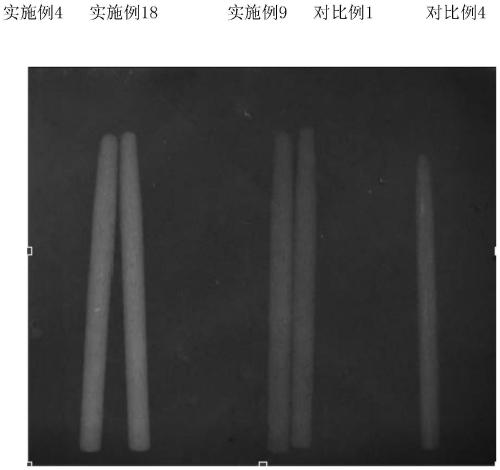

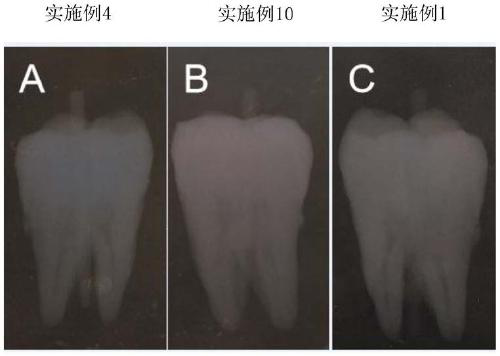

A preparation process and fiber technology, which is applied in the field of strong radiation-resistant fiber posts and its preparation technology, can solve the problems of inability to accurately distinguish fiber posts and tooth bodies, difficulty in uniform dispersion, and poor development effect, etc., to achieve good development effect, Avoid the effects of uneven dispersion and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

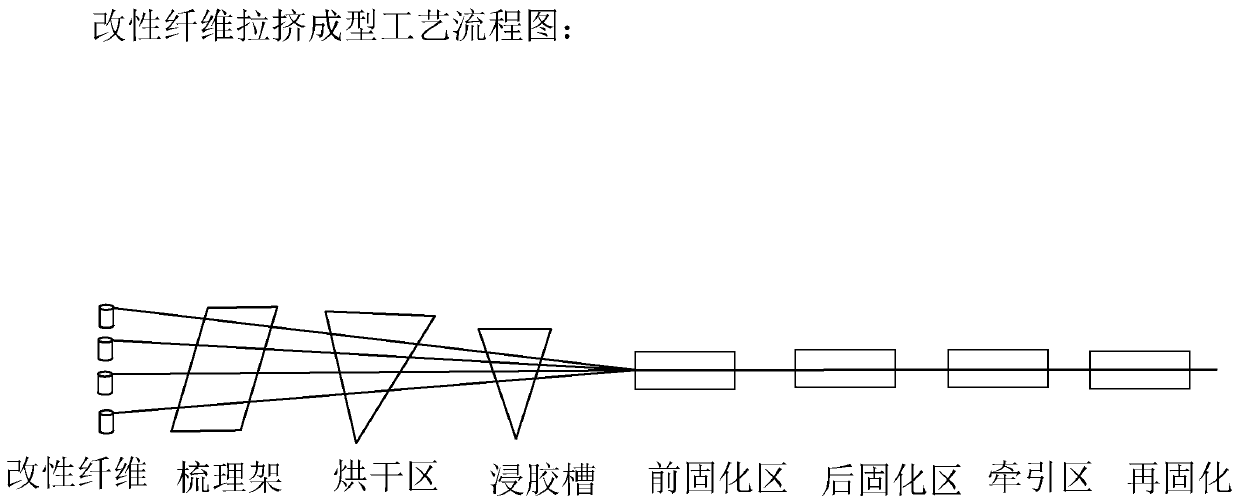

Method used

Image

Examples

preparation example 1

[0068] The preparation steps of modified fiber are as follows:

[0069] S1, 54kg SiO 2 、14kg Al 2 o 3 、7kg B 2 o 3 , 20kg CaO and 20kg zirconia are added to the grinding equipment to prepare batches with an average particle size of 30 μm;

[0070] S2. Put the batch material into the melting furnace and melt it to obtain a stable molten liquid, the liquidus temperature of the molten liquid is 1180°C;

[0071] S3. Make the molten liquid leak from the leakage hole of the platinum alloy leakage plate evenly distributed with 4000 leakage holes. The diameter of the leakage hole is 1mm. The molten liquid coming down from the leakage hole flows to the wire drawing furnace through the passage for wire drawing. The temperature is 1600°C;

[0072]S4. The fiber coming out of the wire drawing furnace is rapidly cooled by a water mist sprayer to shape the drawn fiber; then it passes through an oiler equipped with a sizing agent, and the filamentary fibers are collected into bundles du...

preparation example 2

[0076] The preparation steps of modified fiber are as follows:

[0077] S1, 54kg SiO 2 、14kg Al 2 o 3 、7kg B 2 o 3 , 20kg CaO and 20kg zirconia are added to the grinding equipment to prepare batches with an average particle size of 100 μm;

[0078] S2. Put the batch material into the melting furnace and melt it to obtain a stable molten liquid, the liquidus temperature of the molten liquid is 1180°C;

[0079] S3. Make the molten liquid leak from the leakage hole of the platinum alloy leakage plate evenly distributed with 4000 leakage holes. The diameter of the leakage hole is 2mm. The molten liquid coming down from the leakage hole flows to the wire drawing furnace through the passage for wire drawing. The temperature is 1300°C;

[0080] S4. The fiber coming out of the wire drawing furnace is rapidly cooled by a water mist sprayer to shape the drawn fiber; then it passes through an oiler equipped with a sizing agent, and the filamentary fibers are collected into bundles ...

preparation example 3

[0084] The preparation steps of modified fiber are as follows:

[0085] S1, 54kg SiO 2 、14kg Al 2 o 3 、7kg B 2 o 3 , 20kg CaO and 20kg zirconia are added in the grinding equipment to prepare batches with an average particle size of 55 μm;

[0086] S2. Put the batch material into the melting furnace and melt it to obtain a stable molten liquid, the liquidus temperature of the molten liquid is 1180°C;

[0087] S3. Make the molten liquid leak from the leakage hole of the platinum alloy leakage plate evenly distributed with 4000 leakage holes. The diameter of the leakage hole is 2mm. The molten liquid coming down from the leakage hole flows to the wire drawing furnace through the passage for wire drawing. The temperature is 1450°C;

[0088] S4. The fiber coming out of the wire drawing furnace is rapidly cooled by a water mist sprayer to shape the drawn fiber; then it passes through an oiler equipped with a sizing agent, and the filamentary fibers are collected into bundles d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com