Shaft gravity type stock bin

A gravity-type, silo technology, applied in the field of automated production equipment, can solve problems such as high labor costs, difficult manufacturing, and high prices, and achieve the effects of being easy to grab by manipulators, improving efficiency, and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

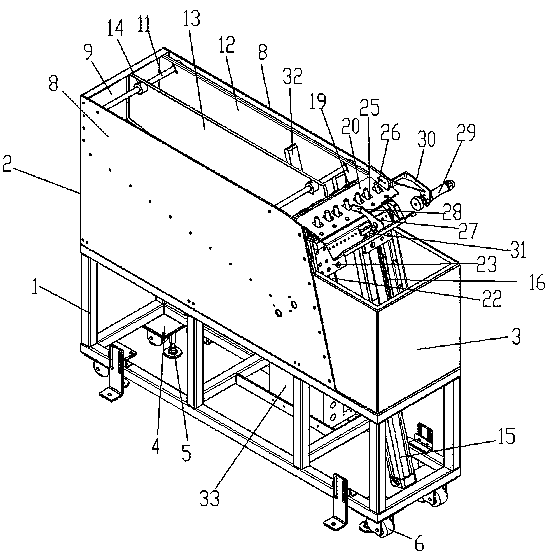

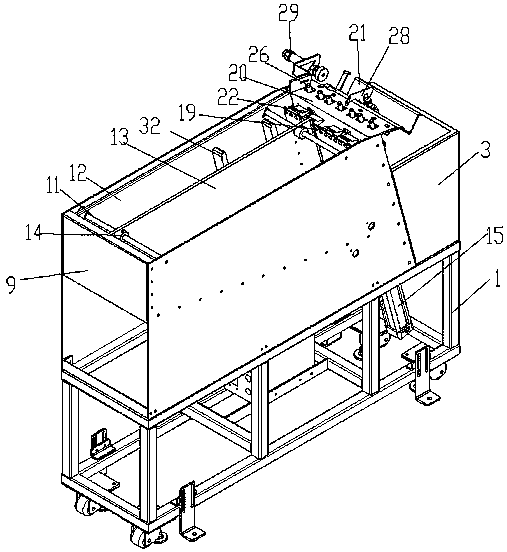

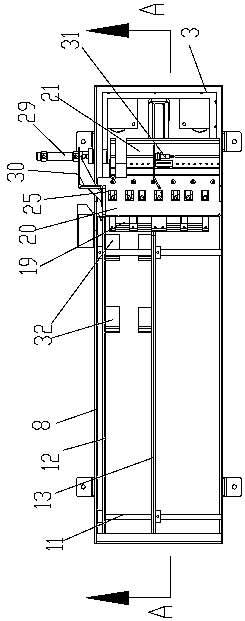

[0030] Such as Figure 1~5 As shown, the present invention discloses a shaft-type gravity feed bin, which is mainly aimed at feeding various metals, plastics, nylon and other cylindrical bars. Its structure includes a support frame 1, which is installed on the The upper storage bin 2 is installed on the support frame 1 and is located at the U-shaped protective plate 3 at the front end of the storage bin, and the jacking and feeding mechanism installed on the front end of the storage bin. inside the shield.

[0031] Specifically, the support frame 1 is a frame structure composed of a plurality of aluminum alloy pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com