Environment-friendly automobile glass

An automotive glass and environmental protection technology, applied in the direction of coating, etc., can solve the problems of affecting the space environment of the car room, the difficulty of removing organic matter, and the narrow space of the car, and achieve the effects of reducing infrared radiation, low cost, and removing the cost of filming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

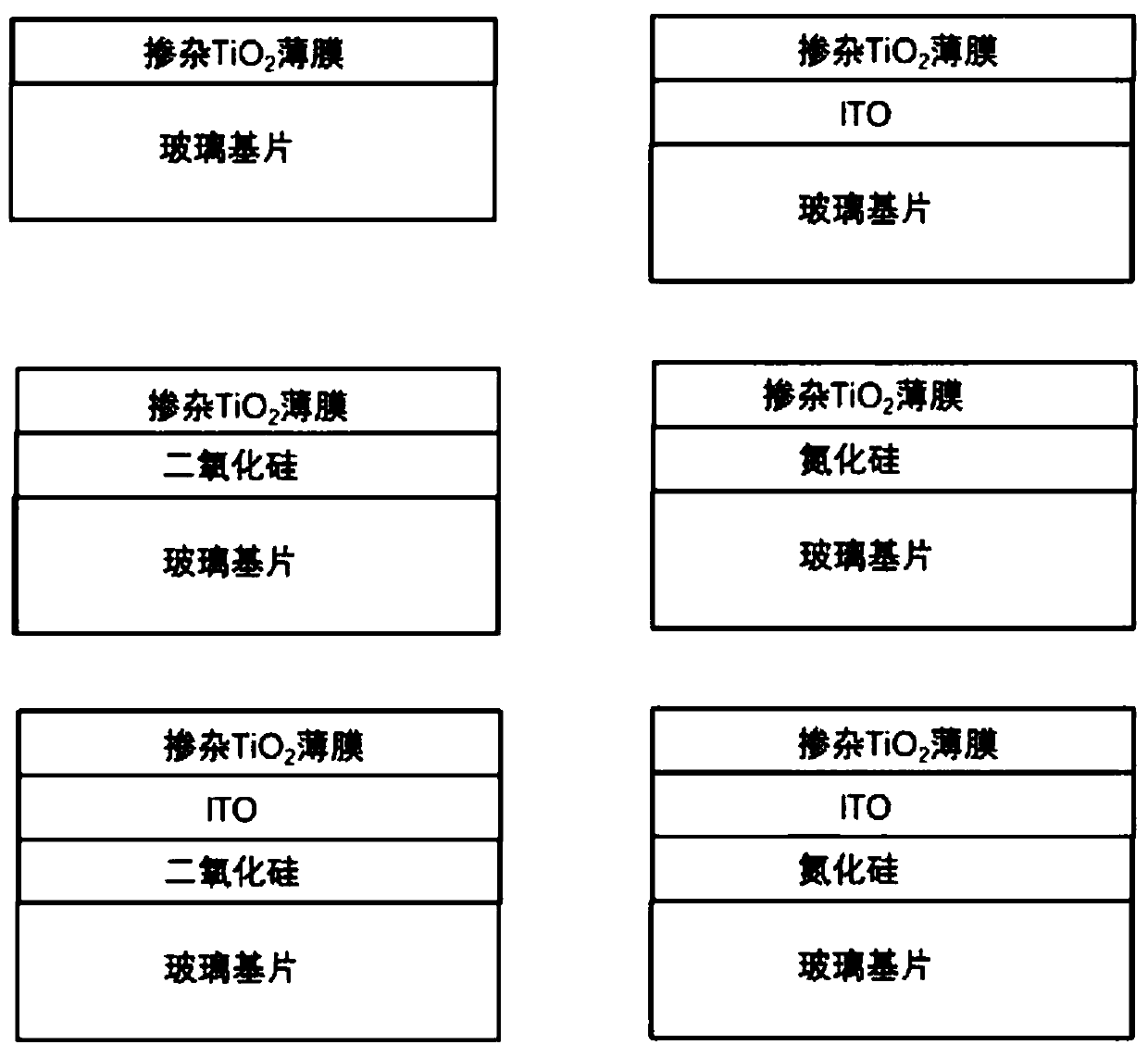

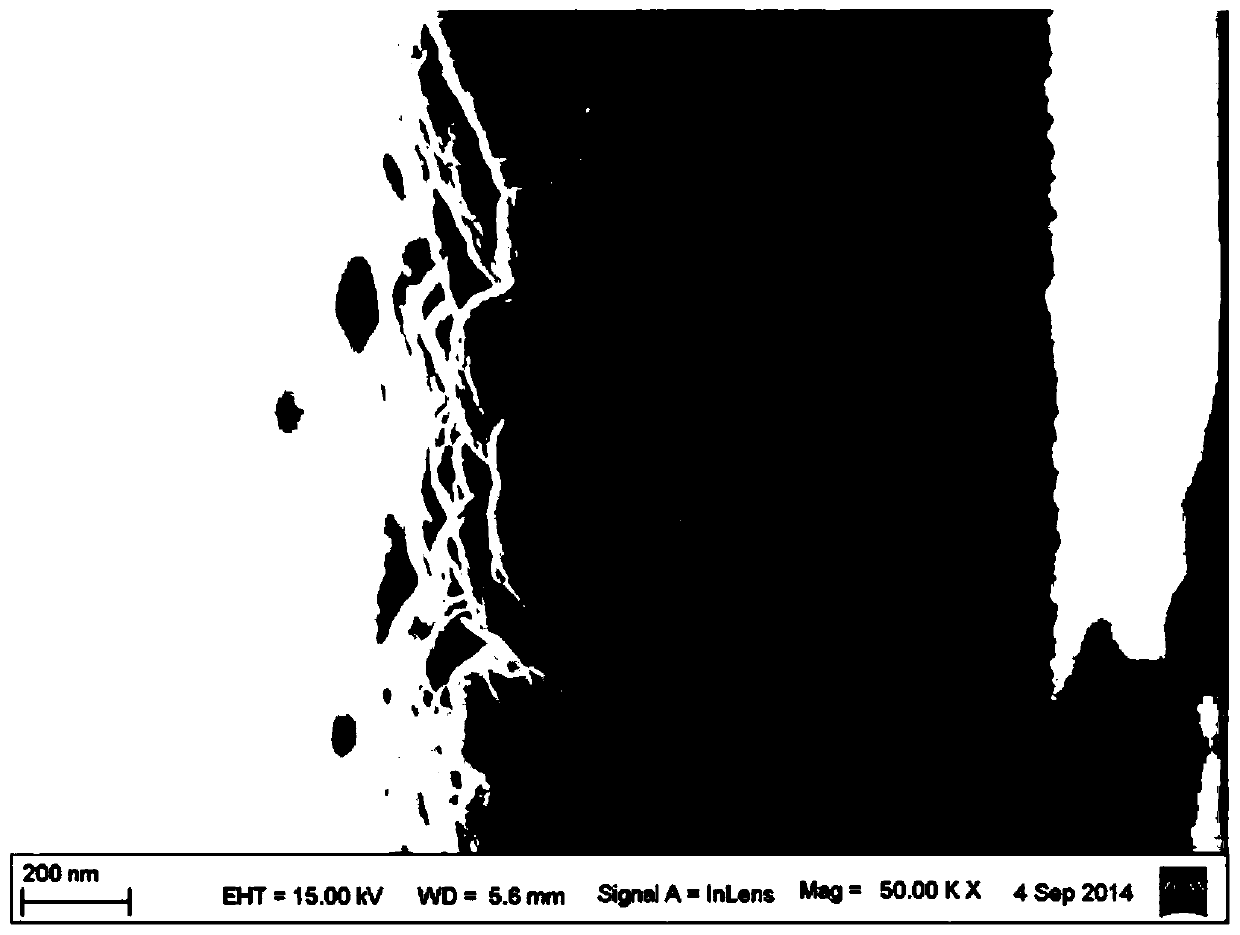

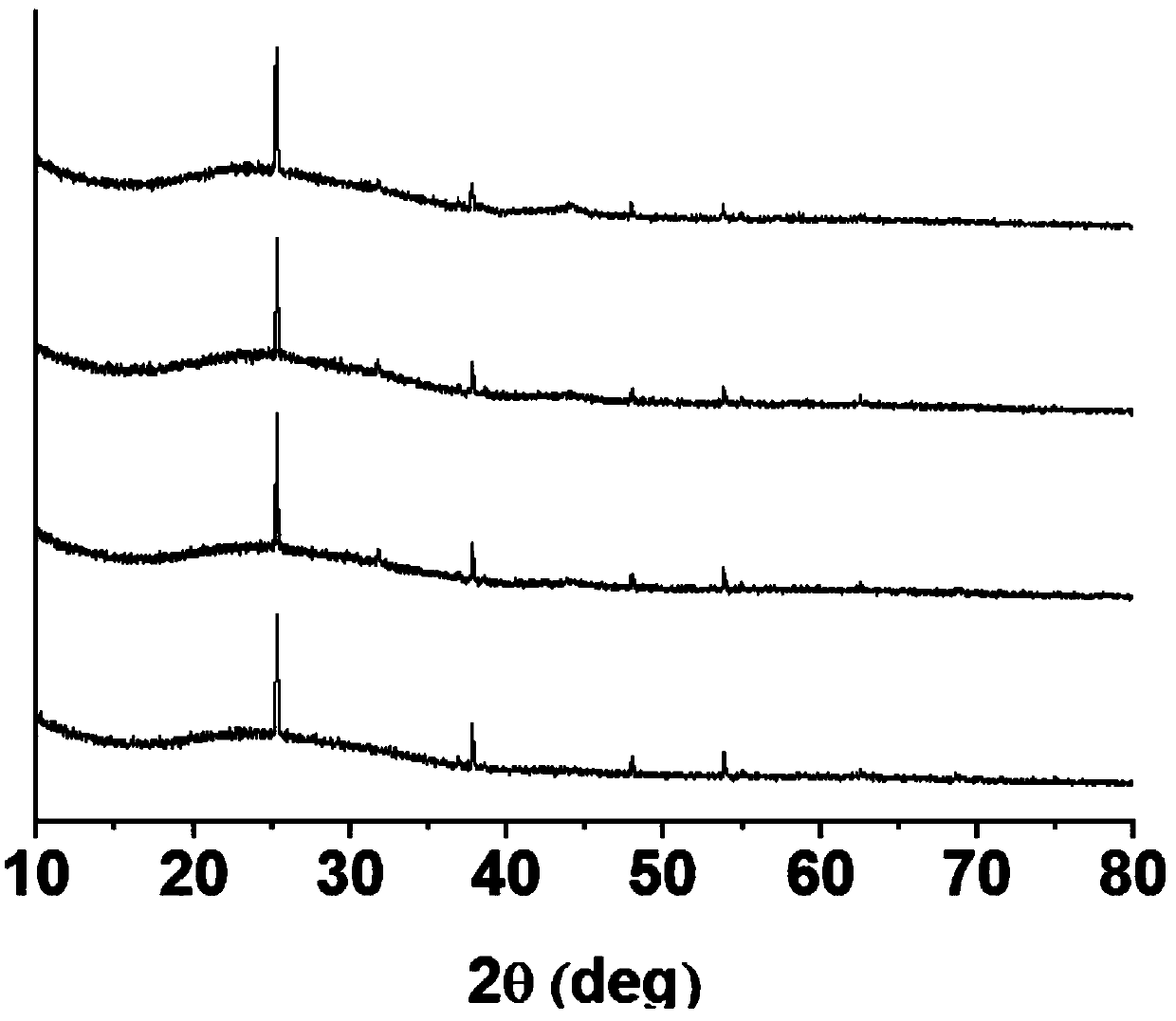

[0041] In this example, the composite layer of automobile glass is prepared by sputtering method, and the specific preparation method is as follows.

[0042] (1) Automobile glass cleaning: Automobile glass is explosion-proof glass, soaked in glass cleaning solution for 10 minutes, rinsed with high-pressure water gun for 5 minutes, dried with air gun, placed in a drying oven at 105°C for 30 minutes, and prepared for subsequent coating.

[0043] (2) Preparation of silicon dioxide layer: adopt radio frequency sputtering method, the target material is silicon dioxide, and the background vacuum of the sputtering chamber is 2×10 -4 Pa, nitrogen gas was introduced, the chamber was vacuum-conditioned to 1Pa, the radio frequency power was turned on, the power was set to 15W, and a 20nm silicon dioxide film was sputtered.

[0044] (3) Preparation of ITO thin film: DC sputtering method is adopted, the target material is ITO, and the background vacuum of the sputtering chamber is 2×10 -4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com